Dual-degradation heatproof food package film

A food packaging film, double-degradation technology, applied in packaging, household packaging, packaged food, etc., can solve problems such as environmental pollution, difficult natural degradation, and hindering economic development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

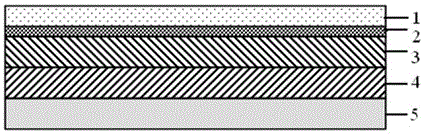

[0024] Such as figure 1 As shown, a double-degradable heat-resistant food packaging film has a layered structure, which is a transparent heat-resistant protective layer (1), a printing layer (2), a printing substrate layer (3), and a photodegradable barrier layer from the outside to the inside. layer (4) and a biodegradable heat-sealing layer (5), wherein the transparent protective layer (1) is an ethylene-vinyl acetate copolymer added with a benzophenone photosensitizer and a particle size of 20 nm fumed silica, with a thickness of 10 microns, the printing substrate layer (3) is a biaxially oriented polyamide added with benzophenone photosensitizer, the thickness is 20 microns, the photodegradable barrier layer (4) is a polymer of methyl ketone and ethylene, the thickness The biodegradable heat-sealing layer (5) is polylactic acid with a thickness of 20 microns, and the adjacent layers of the double-degradable food packaging film are bonded by heat and pressure.

Embodiment 2

[0026] A double-degradable heat-resistant food packaging film, which is a layered structure, from the outside to the inside is a transparent heat-resistant protective layer (1), a printing layer (2), a printing substrate layer (3), and a photodegradable barrier layer (4 ) and a biodegradable heat-sealing layer (5), wherein the transparent protective layer (1) is an ethylene-vinyl acetate copolymer added with a benzophenone photosensitizer and a particle size of 30 nm fumed silica, with a thickness of 20 microns, The printing substrate layer (3) is biaxially stretched polypropylene with a ferrocene photosensitizer added, with a thickness of 40 microns, and the photodegradable barrier layer (4) is a polymer of methacrylketone and ethylene, with a thickness of 40 microns. The biodegradable heat-sealing layer (5) is polycaprolactone with a thickness of 40 microns, and the adjacent layers of the double-degradable food packaging film are bonded by heat and pressure.

Embodiment 3

[0028] A double-degradable heat-resistant food packaging film, which is a layered structure, from the outside to the inside is a transparent heat-resistant protective layer (1), a printing layer (2), a printing substrate layer (3), and a photodegradable barrier layer (4 ) and a biodegradable heat-sealing layer (5), wherein the transparent protective layer (1) is an ethylene-vinyl acetate copolymer added with a benzophenone photosensitizer and a particle size of 50 nanometers of fumed silica, with a thickness of 30 microns, The printing substrate layer (3) is polyethylene terephthalate added with iron stearate photosensitizer, the thickness is 50 microns, and the photodegradable barrier layer (4) is the polymerization of vinyl alcohol cinnamate and ethylene The biodegradable heat-sealing layer (5) is polyester amide with a thickness of 50 microns, and the adjacent layers of the double-degradable food packaging film are bonded by heat and pressure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com