Preparation method for double-chamber MEMS atomic vapor cell

A technology of atomic gas chambers and gas chambers, which is applied in the field of preparation of double-cavity MEMS atomic gas chambers, can solve problems affecting the long-term stability of CPT atomic clocks, difficult engineering implementation, and high difficulty coefficients, so as to achieve mass production and improve Performance, the effect of improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below with reference to the drawings and embodiments.

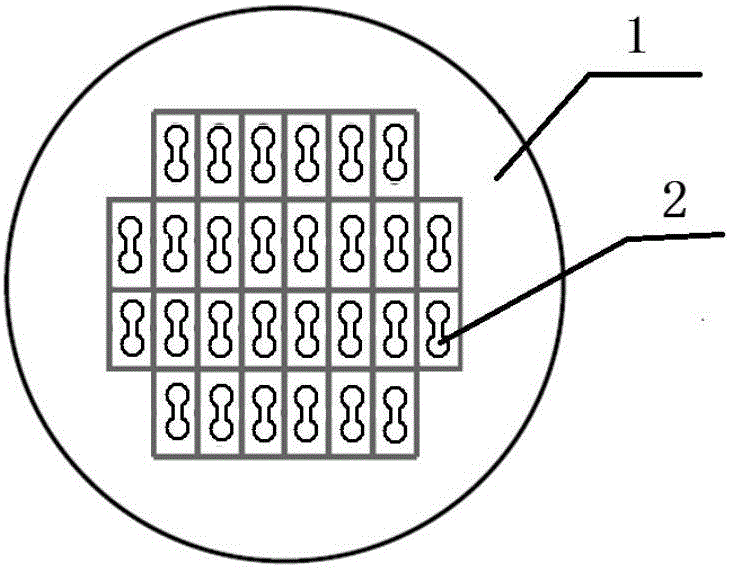

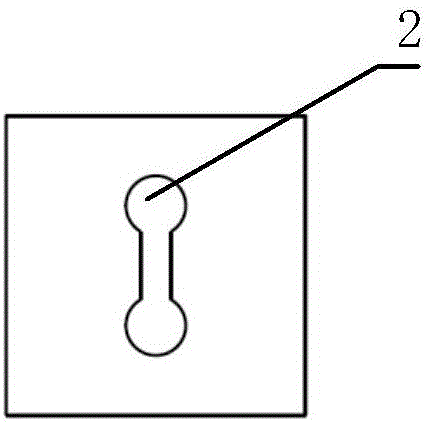

[0024] See Figure 1(a), Figure 1(b), Figure 2(a), Figure 2(b) and image 3 , The preparation method of MEMS atomic gas chamber includes the completion of the 4-inch silicon wafer dual cavity array design and processing, the completion of the bonding of the "glass-silicon wafer-glass" structure, the completion of the cutting and end treatment of a single dual-cavity MEMS atomic gas chamber and the double To connect the cavity-type MEMS atomic gas chamber to the thin glass conduit, the specific steps are as follows:

[0025] (1) Design and processing of dual-cavity MEMS atomic gas chamber 4 inch silicon wafer dual-cavity array:

[0026] a. The wafer uses a silicon wafer with a diameter of 4 inches and a thickness of 1 mm;

[0027] b. Complete the 4-inch silicon wafer dual-cavity array (1) design;

[0028] c. Complete the glass (5)-silicon wafer (6)-glass (7) dual-cavity MEMS a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com