Compound low-phosphorous corrosion inhibition and scale inhibition medicament and preparation method thereof

A technology of corrosion and scale inhibition and medicament, which is applied in the field of compound low-phosphorus corrosion and scale inhibition medicament and its preparation, can solve the problems of ecological destruction, eutrophication of water body, etc., achieve reduced usage, low total phosphorus content, suitable for The effect of biodegradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

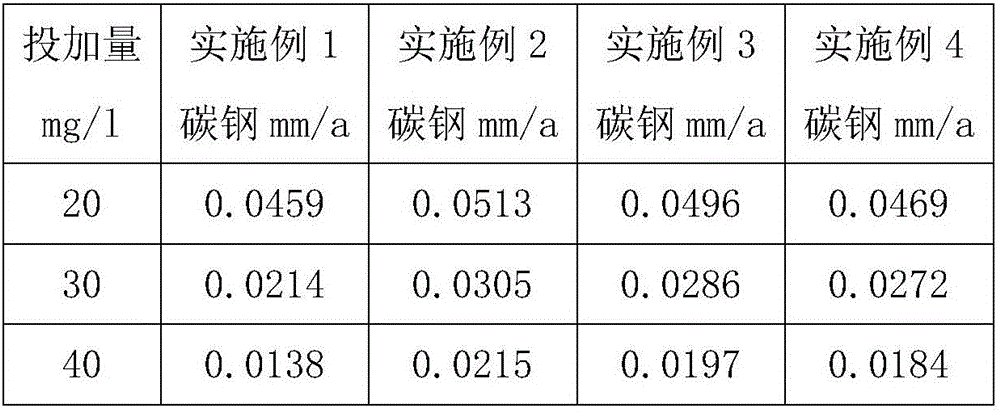

Embodiment 1

[0033] 20 parts of heptadecenyl hydroxyethyl imidazoline quaternary ammonium salt (OED produced by Qinhuangdao Shengli Chemical Co., Ltd.); 15 parts of polyaspartic acid; 2-phospho-1,2,4-tricarboxylic butane Add 10 parts and 30 parts of water into the reaction kettle, and then stir at a rotation speed of 100 rpm. After the solution is uniformly mixed, raise the temperature to 45°C and continue stirring for 20 minutes to obtain solution A;

[0034] Add 8 parts of hexadecyldimethyl (2-sulfite) ethylammonium (produced by Hebei Lanqing Water Treatment Technology Co., Ltd.) into solution A, adjust the rotation speed to 150rpm and mix and stir to make it completely dissolved, then add anhydrous chlorine 13 parts of zinc chloride, continue to stir until the solution is clear, then add 5 parts of dimethylformamide and continue to stir for 30 minutes, keep warm for 2 hours, mix well, cool and stand still, and the finished product is obtained.

Embodiment 2

[0036] 17 parts of heptadecenyl hydroxyethyl imidazoline quaternary ammonium salt (OED produced by Qinhuangdao Shengli Chemical Co., Ltd.); 18 parts of polyaspartic acid; 2-phospho-1,2,4-tricarboxylic butane Add 8 parts and 38 parts of water into the reaction kettle, and then stir at a rotation speed of 110 rpm. After the solution is uniformly mixed, raise the temperature to 40°C and continue stirring for 30 minutes to obtain solution A;

[0037] Add 5 parts of hexadecyldimethyl (2-sulfurous acid) ethyl ammonium (produced by Hebei Lanqing Water Treatment Technology Co., Ltd.) into solution A, adjust the rotation speed to 150rpm and mix and stir to make it completely dissolved, then add sulfuric acid heptahydrate 20 parts of zinc, continue to stir until the solution is clear, then add 4 parts of dimethylformamide and continue to stir for 30 minutes, keep warm for 2 hours, mix well, cool and stand still, and the finished product is obtained.

Embodiment 3

[0039] 23 parts of heptadecenyl hydroxyethyl imidazoline quaternary ammonium salt (OED produced by Qinhuangdao Shengli Chemical Co., Ltd.); 13 parts of polyaspartic acid; 2-phospho-1,2,4-tricarboxylic butane Add 13 parts and 35 parts of water into the reaction kettle, and then stir at a rotation speed of 110 rpm. After the solution is uniformly mixed, heat up to 50°C and continue stirring for 25 minutes to obtain solution A;

[0040] Add 10 parts of hexadecyldimethyl (2-sulfite) ethyl ammonium (produced by Hebei Lanqing Water Treatment Technology Co., Ltd.) into solution A, adjust the rotation speed to 150rpm and mix and stir to make it completely dissolved, then add anhydrous chlorine 11 parts of zinc chloride, continue to stir until the solution is clear, then add 5 parts of dimethylformamide and continue to stir for 30 minutes, keep warm for 2 hours, mix well, cool and stand still, and the finished product is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com