Fly ash based geopolymer grouting material and preparation method for same

A technology of fly ash and grouting materials, which is applied in the field of building materials, can solve the problems of low strength in the later stage, low strength in the later stage, and short setting time, and achieve high early strength and later strength, good fluidity and workability, and preparation The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Prepare raw materials according to the following components and weight: 20kg of modified water glass, 30kg of fly ash, 10kg of metakaolin, 5kg of ordinary Portland cement with a label grade of 42.5, 60kg of natural river sand with a fineness modulus of 2.3, and 0.05 sucrose kg, alkyl silicone oil 0.03kg, hydroxypropyl methylcellulose ether 0.01kg, water 10kg.

[0029] Prepare the fly ash base polymer grout according to the following steps:

[0030] (1) use sodium hydroxide to adjust the modulus of modified water glass to be 1.0, and the concentration is 30%;

[0031] (2) Mix the adjusted modified water glass with other raw materials, stir for 3 minutes, let stand for 1 minute, and then stir for 2 minutes to obtain the grouting material.

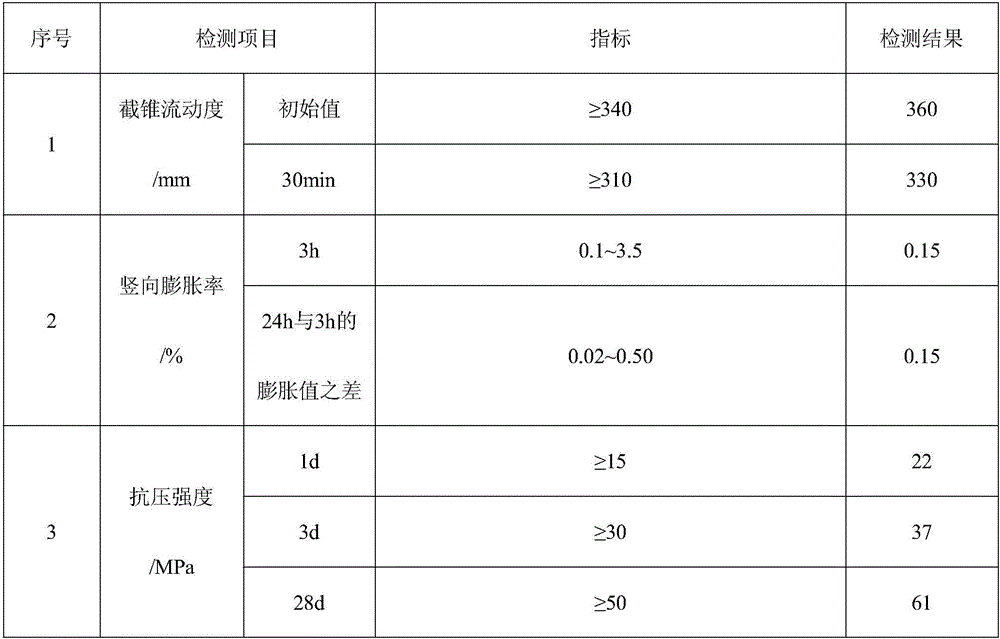

[0032] The performance test results of the grouting material prepared according to the above method are as follows:

[0033]

[0034]

Embodiment 2

[0036] Prepare raw materials according to the following components and weights: 20kg of modified water glass, 40kg of fly ash, 5kg of ordinary Portland cement with a label grade of 42.5R, 60kg of quartz sand with a fineness modulus of 2.5, 0.05kg of citric acid, castor Sesame oil 0.03kg, hydroxypropyl methylcellulose ether 0.01kg, water 10kg.

[0037] Prepare the fly ash base polymer grout according to the following steps:

[0038] (1) use sodium hydroxide to adjust the modulus of modified water glass to be 1.2, and the concentration is 35%;

[0039] (2) Mix the adjusted modified water glass with other raw materials, stir for 4 minutes, let stand for 1.5 minutes, and then stir for 2.5 minutes to obtain the grout.

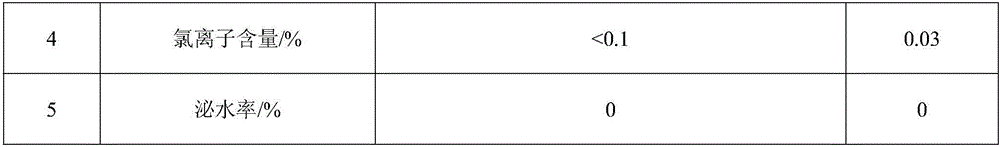

[0040] The performance test results of the grouting material prepared according to the above method are as follows:

[0041]

[0042]

Embodiment 3

[0044] Prepare raw materials according to the following components and weight: 20kg of alkali activator, 30kg of fly ash, 5kg of metakaolin, 10kg of ordinary Portland cement with a grade of 42.5, 60kg of quartz sand with a fineness modulus of 2.8, and 0.05 barium chloride kg, palm oil 0.03kg, hydroxyethyl methylcellulose ether 0.01kg, water 10kg.

[0045] Prepare the fly ash base polymer grout according to the following steps:

[0046] (1) use sodium hydroxide to adjust the modulus of modified water glass to be 1.2, and the concentration is 35%;

[0047] (2) Mix the adjusted modified water glass with other raw materials, stir for 4 minutes, let stand for 1.5 minutes, and then stir for 2.5 minutes to obtain the grout.

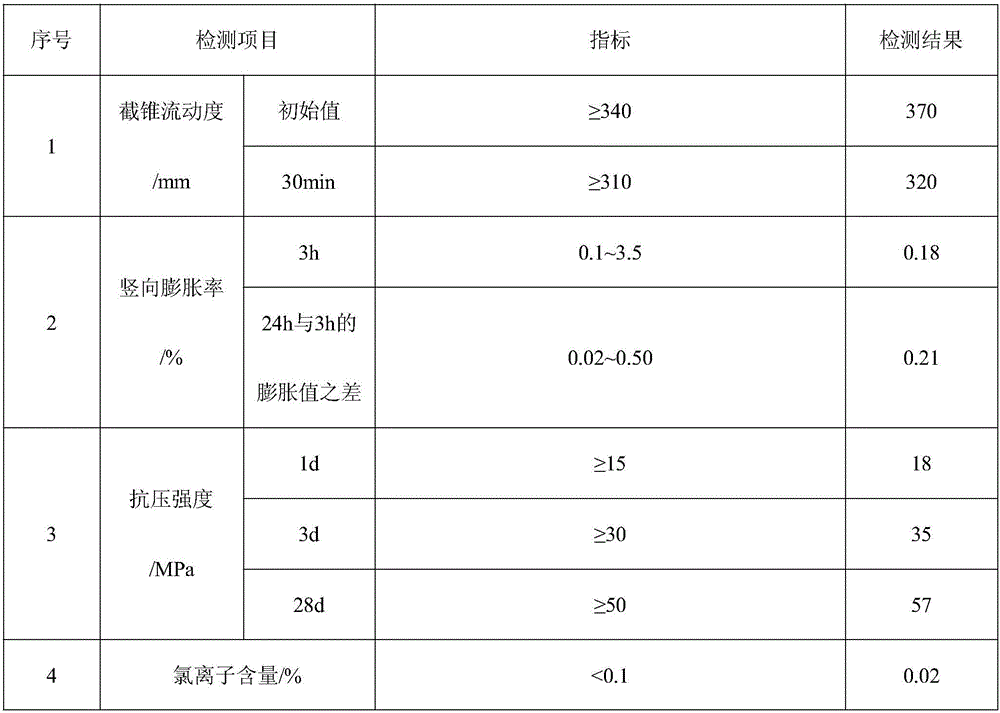

[0048] The performance test results of the grouting material prepared according to the above method are as follows:

[0049]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com