Method and device for synthesizing ethyl lactate by using vapor permeation dehydration technology

A technology of ethyl lactate and osmotic dehydration, which is applied in the separation/purification of carboxylic acid esters, preparation of carboxylic acid esters, chemical instruments and methods, etc., can solve the problem that lactic acid cannot be recycled and reused, the amount of evaporation cannot be accurately controlled, and ethyl lactate Solve the problems of high water content in ester products, and achieve the effects of low organic matter content, high dehydration efficiency and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

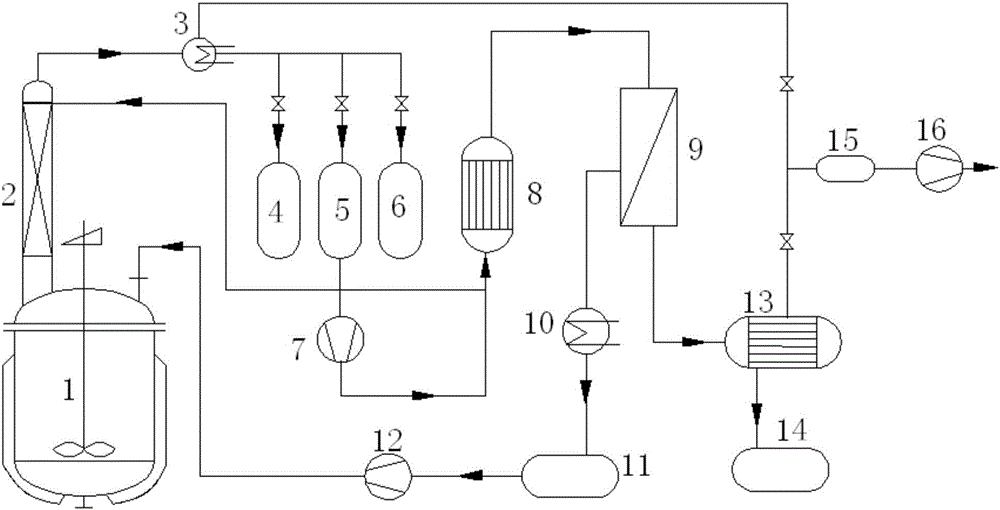

[0029] Such as figure 1As shown, 2.5kg of lactic acid (water content about 20%) was put into the reactor, and after vacuum distillation, the amount of distilled water was 0.4kg. After cooling slightly, 3.65L of absolute ethanol and 0.04kg of catalytic resin were put into it. After heating, the esterification reaction is carried out under the catalysis of the catalyst. The temperature in the reactor is 85~90°C, and the temperature at the top of the rectification column is controlled at about 76°C. The height of the rectification column is 0.8 m and the diameter of the column is about 37 mm, the rectification column is filled with 3 mm × 0.5 mm glass spring packing. The rising steam and the descending reflux liquid in the reactor conduct heat and mass transfer in the rectification column, part of the overhead distillate is used as the reflux liquid with a reflux ratio of 1.5, and the other part is used as the raw material liquid for the steam permeation dehydration process, eva...

Embodiment 2

[0031] like figure 1 As shown, 4kg of lactic acid (water content about 20%) was put into the reactor, and after vacuum distillation, the amount of distilled water was 0.53kg. After cooling down slightly, add 6.67L absolute ethanol and 0.032kg (accurately measured) concentrated sulfuric acid. After heating, the esterification reaction is carried out under the catalysis of the catalyst. The temperature in the reactor is 85~90°C, and the temperature at the top of the rectification column is controlled at about 76°C. The height of the rectification column is 0.8 m and the diameter of the column is about 37 mm. , the rectification column is filled with 3 mm × 0.5 mm glass spring packing. The rising steam and the descending reflux liquid in the reactor conduct heat and mass transfer in the rectification column, part of the overhead distillate is used as the reflux liquid, and the reflux ratio is 2, and the other part is used as the raw material liquid for the steam permeation dehyd...

Embodiment 3

[0033] like figure 1 As shown, 3kg of lactic acid (water content about 20%) was put into the reactor, and after vacuum distillation, the amount of distilled water was 0.45kg. After cooling down slightly, add 4.6L absolute ethanol and 0.024kg (accurately measured) concentrated sulfuric acid. After heating, the esterification reaction is carried out under the catalysis of the catalyst. The temperature in the reactor is 85~90°C, and the temperature at the top of the rectification column is controlled at about 76°C. The height of the rectification column is 0.8m and the diameter of the column is about 37 mm. , the rectification column is filled with 3 mm × 0.5 mm glass spring packing. The rising steam and the descending reflux liquid in the reactor conduct heat and mass transfer in the rectification column, part of the overhead distillate is used as the reflux liquid, and the reflux ratio is 2, and the other part is used as the raw material liquid for the steam permeation dehydra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com