Waterborne alkyd enamel paint and preparation method thereof

A water-based alkyd and water-based alkyd resin technology, used in magnetic coatings, coatings, anti-corrosion coatings, etc., can solve the problems of water resistance and mechanical properties that are not easy to meet high requirements, slow drying, etc. Low, the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

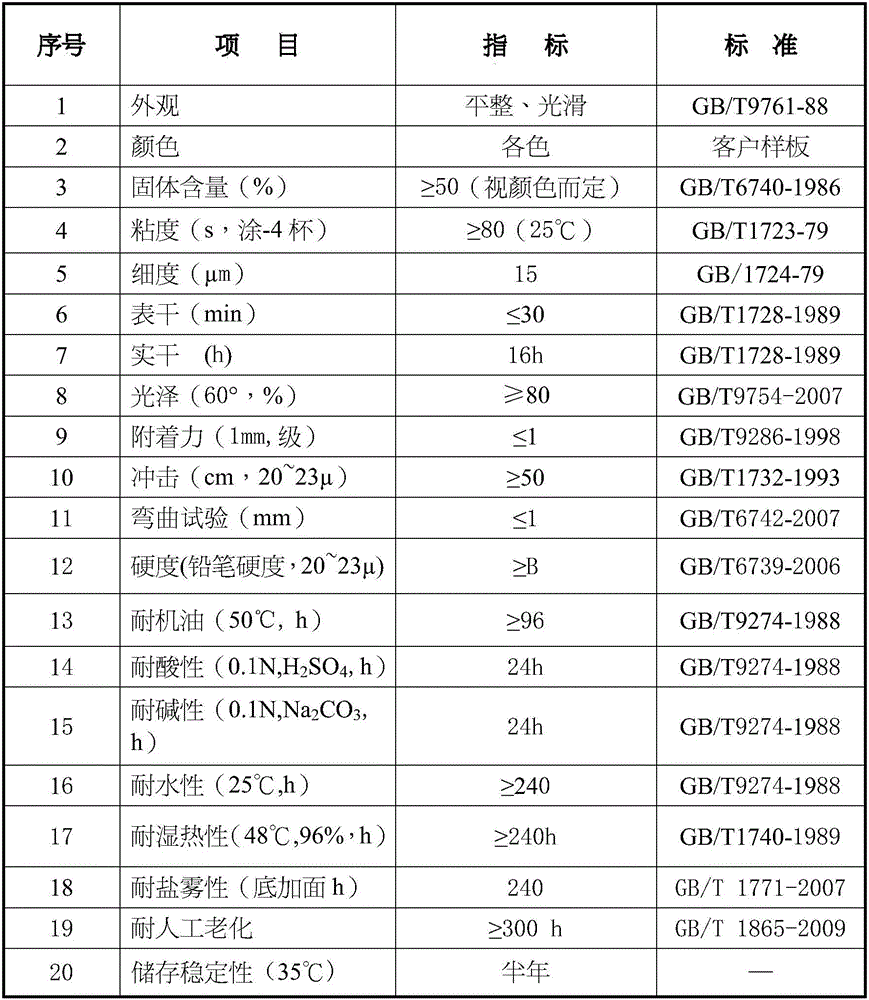

Examples

Embodiment 1

[0026] A kind of water-based alkyd enamel of the present embodiment mainly comprises the raw material of following weight ratio: model is 8 parts of water-based alkyd resins of YD-67, model is 10 parts of water-based epoxy modified alkyd resins of YD-60, 0.5 parts of neutralizer, 0.55 parts of water-based drier, 0.2 parts of water-based dispersant, 0.05 parts of water-based wetting agent, 0.8 parts of water-based thickener with model YD-612, and water-based modified thickener with model YD-615 0.8 parts of agent, 3 parts of titanium dioxide, 0.1 parts of carbon black, 6 parts of barium sulfate, and 70 parts of water.

[0027] The preparation method of a kind of water-based alkyd enamel of this embodiment is specifically to add the water-based alkyd resin, neutralizer, water-based wetting agent and water-based dispersant in the formula amount into the stirring device, and under the speed of 600 rpm Stir for 20 minutes, adjust the pH value to 8; then add the formula amount of ti...

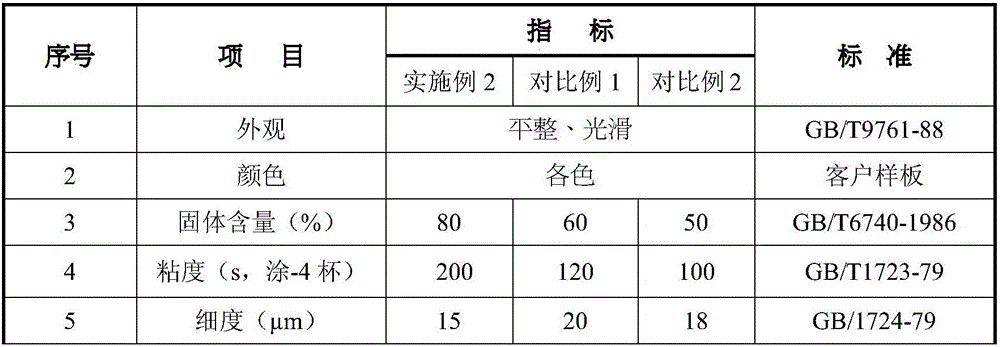

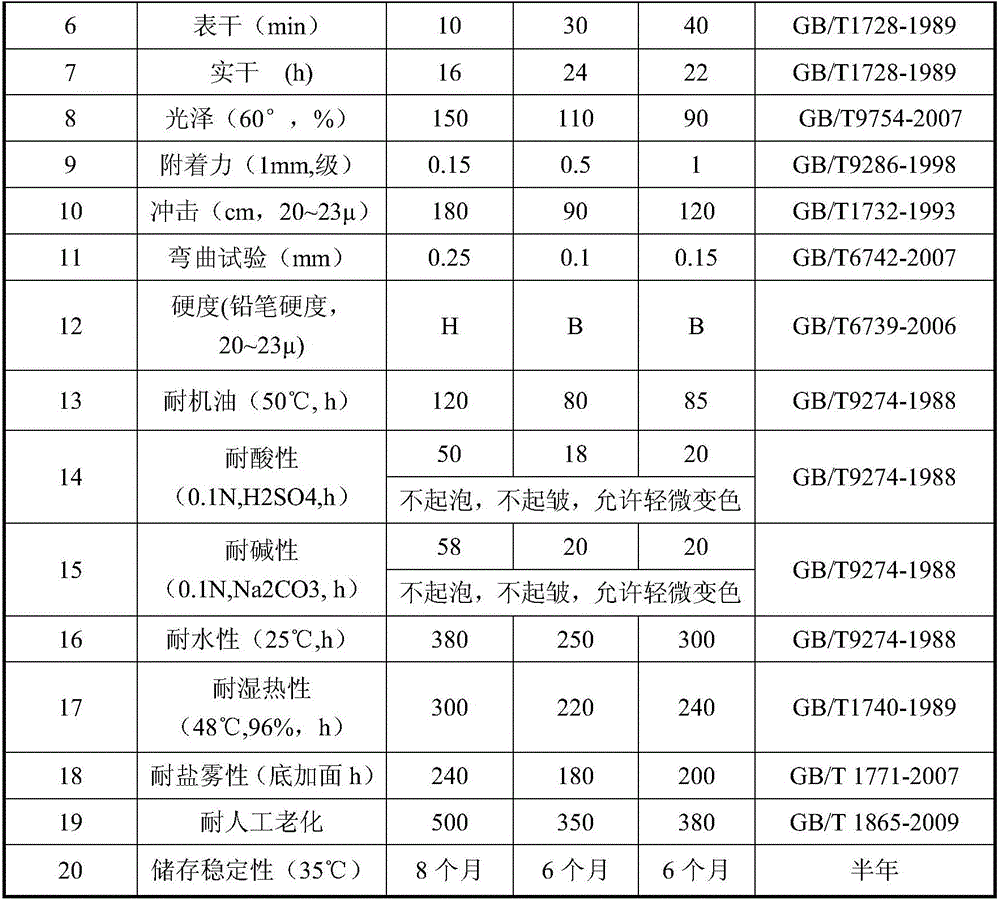

Embodiment 2

[0029] A kind of water-based alkyd enamel of the present embodiment mainly comprises the raw material of following weight ratio: model is 10 parts of water-based alkyd resins of YD-67, model is 15 parts of water-based epoxy modified alkyd resins of YD-60, 1.0 part of neutralizer, 1.0 part of water-based drier, 0.3 part of water-based dispersant, 0.1 part of water-based wetting agent, 1.0 part of water-based thickener with model YD-612, and water-based modified thickener with model YD-615 1.0 parts of agent, 4 parts of titanium dioxide, 0.2 parts of carbon black, 7.5 parts of barium sulfate, and 58.9 parts of water.

[0030] The preparation method of a kind of water-based alkyd enamel of this embodiment is specifically to add the water-based alkyd resin, neutralizing agent, water-based wetting agent and water-based dispersant in the formula amount into the stirring device, at the speed of 700 rpm Stir for 20 minutes, adjust the pH value to 9; then add the formula amount of tita...

Embodiment 3

[0032] A kind of water-based alkyd enamel of the present embodiment mainly comprises the raw material of following weight ratio: model is 15 parts of water-based alkyd resins of YD-67, model is 15 parts of water-based epoxy modified alkyd resins of YD-60, 1.5 parts of neutralizer, 1.5 parts of water-based drier, 0.6 parts of water-based dispersant, 0.1 part of water-based wetting agent, 1.2 parts of water-based thickener with model YD-612, and water-based modified thickener with model YD-615 1.2 parts of agent, 5 parts of titanium dioxide, 0.4 parts of carbon black, 6.5 parts of barium sulfate, and 52 parts of water.

[0033] The preparation method of a kind of water-based alkyd enamel of this embodiment is specifically to add the water-based alkyd resin, neutralizing agent, water-based wetting agent and water-based dispersant in the formula amount into the stirring device, at the speed of 700 rpm Stir for 20 minutes, adjust the pH value to 9; then add the formula amount of ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com