Organic silicon nitrogen anti-flaming regenerated cellulose fiber

A technology of regenerated cellulose and organic silicon, which is applied in the direction of artificial filaments in cellulose solution, chemical post-treatment of cellulose/protein artificial filaments, and manufacture of fire-resistant and flame-retardant filaments, so as to promote blood circulation and metabolism, eliminate Fatigue, the effect of maintaining comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

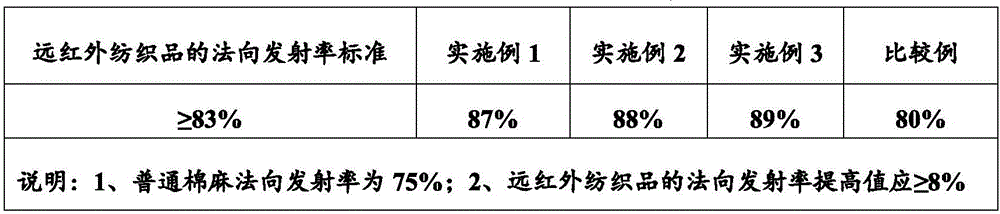

Examples

Embodiment 1

[0028] Inject the organic silicon nitrogen flame retardant of 30wt% to the amount of cellulose into the prepared viscose collagen solution, make the viscose and the flame retardant react for 30 minutes, mix the viscosity of the glue for 70 seconds, and mature (10% ammonium chloride) 10ml. Regenerated in the coagulation bath by spinneret spinning, the coagulation bath composition is sulfuric acid 75g / l, sodium sulfate 160g / l, zinc sulfate 20g / l, temperature 40 ℃. The regenerated fiber tow is drawn, cut, washed, fixed cross-linked, bleached, oiled, dried, packed, and the condition of the fixed cross-linked bath is: fixed cross-linking agent: pure water: sodium bisulfite (weight Ratio)=33:66:1, the treatment time is 15-40 minutes, and the treatment temperature is 75°C.

[0029] SiO in flame retardant 2 、TiO 2 The total content of CaO and CaO is 18.7wt%, and the amide content is 12.5wt%; wherein the ratio (molar ratio) of silicon, titanium and calcium is 5.4:2.7:7.0

Embodiment 2

[0031] Inject the organic silicon nitrogen flame retardant of 33wt% to the amount of cellulose into the prepared viscose collagen solution, make the viscose and the flame retardant react for 50 minutes, mix the viscosity of the glue for 80 seconds, and mature (10% ammonium chloride) 14ml. Regenerated in the coagulation bath by spinneret spinning, the coagulation bath composition is sulfuric acid 100g / l, sodium sulfate 180g / l, zinc sulfate 30g / l, temperature 40°C. The regenerated fiber tow is drawn, cut, washed, fixed cross-linked, bleached, oiled, dried, packed, and the condition of the fixed cross-linked bath is: fixed cross-linking agent: pure water: sodium bisulfite (weight Ratio)=33:66:1, the treatment time is 15-40 minutes, and the treatment temperature is 75°C.

[0032] SiO in flame retardant 2 、TiO 2 The total content of CaO and CaO is 23wt%, and the amide content is 18.7wt%. The ratio (molar ratio) of silicon, titanium and calcium is 6.7:3.5:9.2.

Embodiment 3

[0034]Inject the organic silicon nitrogen flame retardant of 35wt% to the amount of cellulose into the prepared viscose collagen solution, make the viscose and the flame retardant react for 60 minutes, mix the viscosity of the glue for 70 seconds, and mature (10% ammonium chloride) 16ml. Regenerated in the coagulation bath by spinneret spinning, the coagulation bath composition is sulfuric acid 125g / l, sodium sulfate 280g / l, zinc sulfate 50g / l, temperature 45 ℃. The regenerated fiber tow is drawn, cut, washed, fixed cross-linked, bleached, oiled, dried, packed, and the condition of the fixed cross-linked bath is: fixed cross-linking agent: pure water: sodium bisulfite (weight Ratio)=33:66:1, the treatment time is 15-40 minutes, and the treatment temperature is 75°C.

[0035] SiO in flame retardant 2 、TiO 2 The total content of CaO and CaO is 33wt%, and the amide content is 28wt%. The ratio (molar ratio) of silicon, titanium and calcium is 7.2:3.8:12.3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com