A kind of automobile inner lining material with sterilization and deodorization

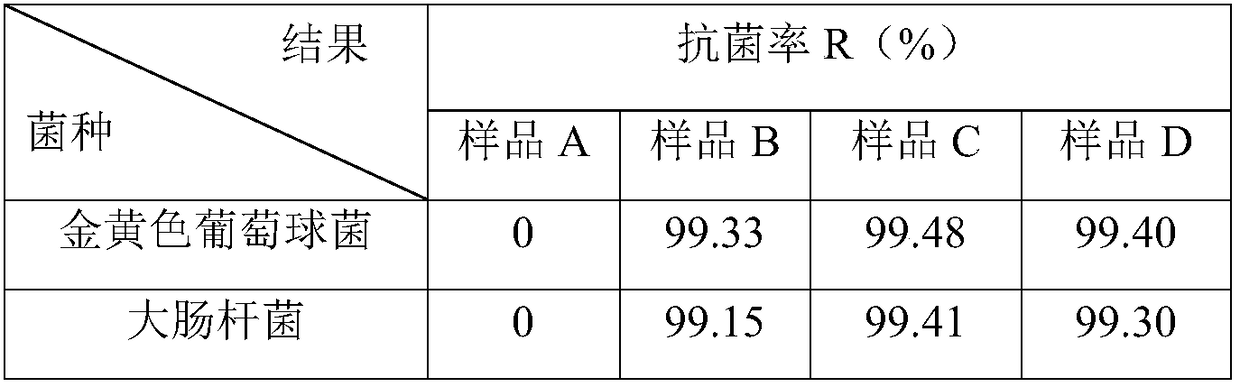

An automobile and lining technology, which is applied in the field of automobile lining materials and non-woven composite materials for automobile lining, can solve the problems of easy breeding of bacteria, mildew, affecting the personal health of passengers, and achieve long-term antibacterial enhancement. The effect of bacteriostatic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A material for automobile inner lining with sterilization and deodorization, which is made of the following components in parts by weight: 100 parts of isotactic polypropylene, 8 parts of maleic anhydride grafted polypropylene, 8 parts of medical stone, lanthanum oxide 3 parts of zinc, 3 parts of titanium dioxide loaded with cerium, 0.3 parts of antioxidant, 8 parts of vermiculite, 0.6 parts of silane coupling agent, 0.2 parts of monoglyceride, 30 parts of polyethylene wax, 20 parts of chitin fiber, 30 parts of carbon nanofiber 30 parts of bamboo fiber, 4 parts of perilla oil, 10 parts of gardenia, 8 parts of Zhuru, 10 parts of Magnolia officinalis, 6 parts of oily mandarin leaves, and 15 parts of Prunella vulgaris.

[0030] The preparation method of the automobile inner lining material with sterilization and deodorization comprises the following steps:

[0031] (1) After mixing medical stone and vermiculite and coarsely pulverizing them, heat them at high temperature f...

Embodiment 2

[0039] A material for automobile inner lining with sterilization and deodorization, which is made of the following components in parts by weight: 120 parts of isotactic polypropylene, 16 parts of maleic anhydride grafted polypropylene, 16 parts of medical stone, lanthanum oxide 5 parts of zinc, 5 parts of titanium dioxide loaded with cerium, 0.5 parts of antioxidant, 16 parts of vermiculite, 1 part of silane coupling agent, 0.4 parts of monoglyceride, 50 parts of polyethylene wax, 30 parts of chitin fiber, 50 parts of carbon nanofiber 40 parts, 40 parts of bamboo fiber, 6 parts of perilla oil, 20 parts of gardenia, 16 parts of Zhuru, 20 parts of Magnolia officinalis, 12 parts of oily mandarin leaves, 25 parts of Prunella vulgaris.

[0040] The preparation method of the automobile inner lining material with sterilization and deodorization comprises the following steps:

[0041] (1) After mixing medical stone and vermiculite and coarsely pulverizing them, heat them at high tempe...

Embodiment 3

[0049] A material for automobile inner lining with sterilization and deodorization, which is made of the following components in parts by weight: 110 parts of isotactic polypropylene, 12 parts of maleic anhydride grafted polypropylene, 12 parts of medical stone, lanthanum oxide 4 parts of zinc, 4 parts of titanium dioxide loaded with cerium, 0.4 parts of antioxidant, 12 parts of vermiculite, 0.8 parts of silane coupling agent, 0.3 parts of monoglyceride, 40 parts of polyethylene wax, 25 parts of chitin fiber, 40 parts of carbon nanofiber 35 parts of bamboo fiber, 5 parts of perilla oil, 15 parts of gardenia, 12 parts of Zhuru, 15 parts of Magnolia officinalis, 9 parts of oily mandarin leaves, 20 parts of Prunella vulgaris.

[0050] The preparation method of the automobile inner lining material with sterilization and deodorization comprises the following steps:

[0051] (1) After mixing medical stone and vermiculite and coarsely pulverizing them, heat them at high temperature f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com