Mechanical grate type waste gasifying and incinerating system and synthesized gas straight tube combustion chamber

A combustion chamber and synthesis gas technology, applied in the combustion method, combustion type, combustion control and other directions, can solve the problems of backward heat treatment mode, lower heat conversion efficiency, easy ash deposition, etc., to improve energy conversion efficiency and heat exchange efficiency. , the effect of preventing secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

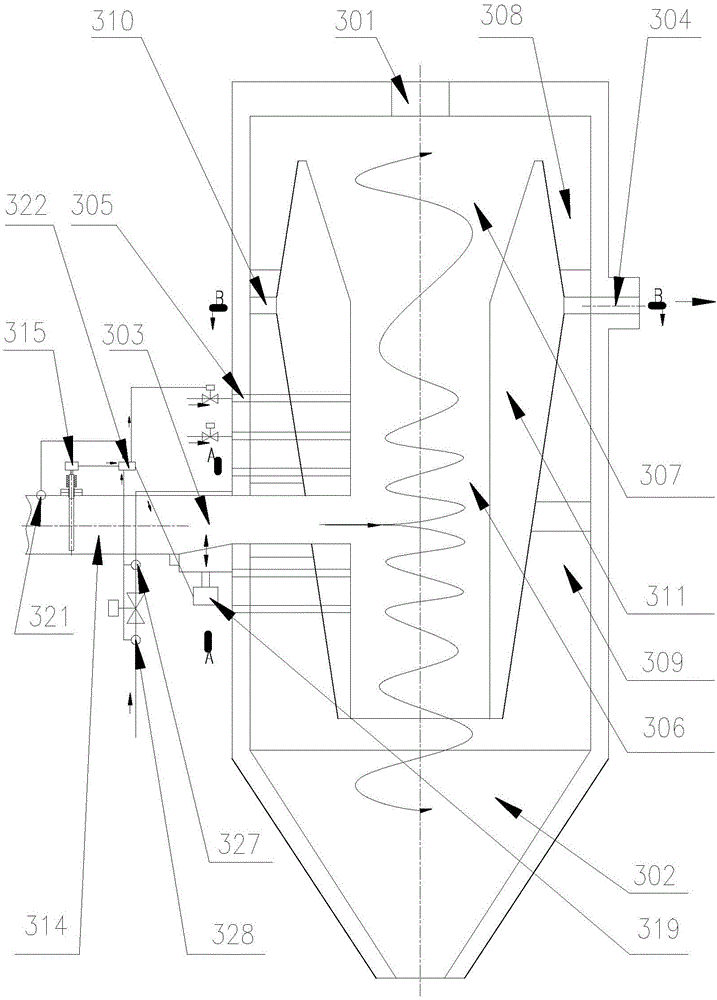

[0043] see Figure 1 to Figure 5 , is a preferred embodiment of the syngas straight tube combustor,

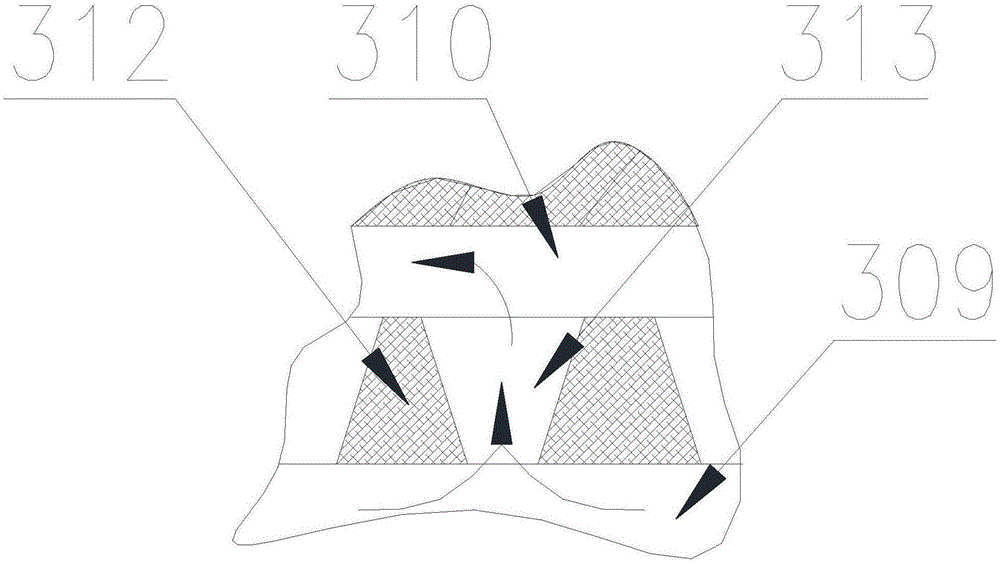

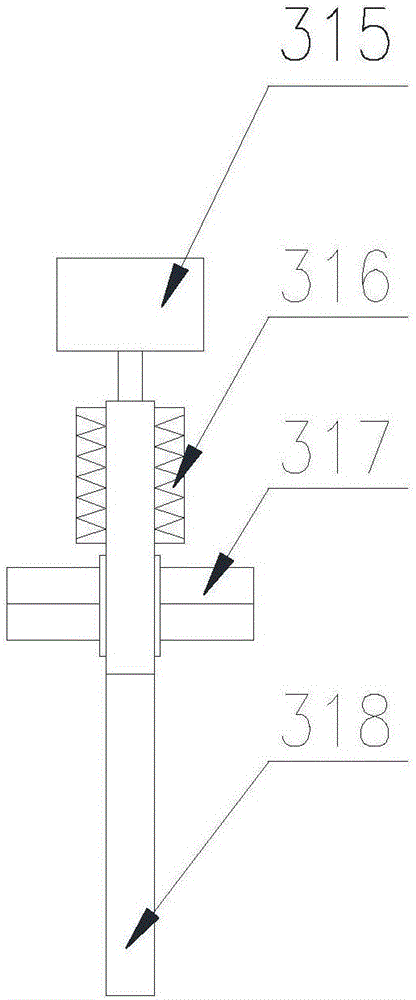

[0044] A straight pipe combustion chamber for synthesis gas, the combustion chamber ignition and combustion-supporting hole 301 is arranged on the top plate of the straight pipe combustion chamber for synthesis gas, and the inner cavity of the straight pipe combustion chamber for synthesis gas includes combustion channels arranged in sequence from top to bottom, The conical slag outlet 302 and the upper annular flue gas passage 308, the annular exhaust flue 310, and the lower annular flue gas passage 309 are arranged in sequence from top to bottom around the combustion channel. , the upper annular flue gas passage 308, the annular exhaust flue 310, the lower annular flue gas passage 309 are separated from the combustion passage by an annular air guide pier 311, and the combustion passage includes a vertical passage 306 at the bottom and The V-cone passage 307 located above th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com