Silicon-based lateral injection laser and preparation method thereof

A laser and lateral technology, applied in the field of silicon-based lateral injection lasers and their preparation, can solve the problems of large lasing threshold of devices, complex germanium materials, large optical loss, etc., to reduce optical absorption loss, simplify process steps, and improve compatibility. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

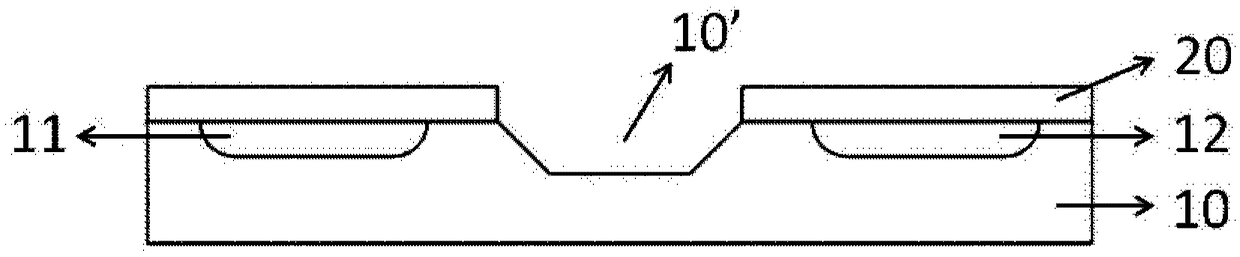

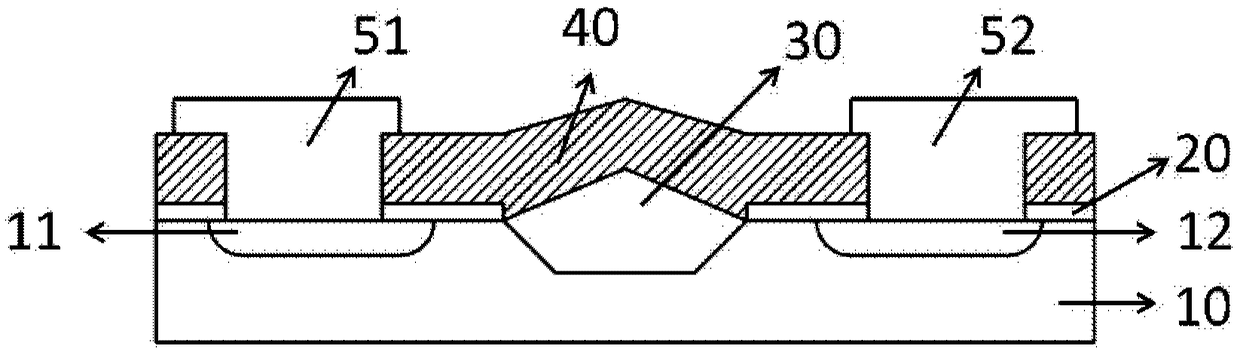

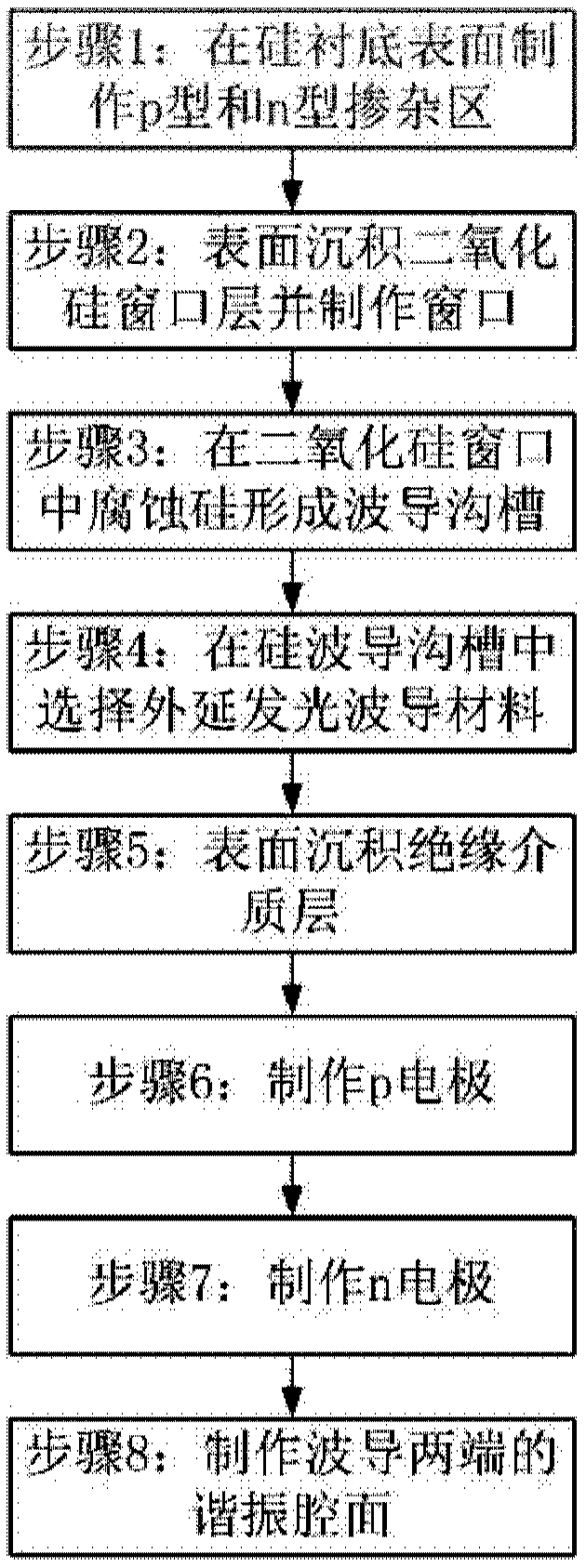

[0029] see figure 1 , figure 2 As shown, the invention provides a silicon-based lateral injection laser, comprising:

[0030] A silicon substrate 10 has a waveguide groove 10' fabricated on its surface, and p-type doped regions 11 and n-type doped regions 12 are respectively fabricated on both sides of the waveguide groove 10'. The silicon substrate 10 has a (001) crystal orientation, wherein the waveguide trenches 10' extend along the (110) crystal orientation. If the waveguide groove 10' is formed by selective wet etching, the sidewall of the waveguide groove 10' is a (111) crystal plane, and the smooth sidewall can reduce the gap between the strip waveguide 30 and the sidewall of the waveguide groove 10'. light scattering loss; if etching or non-selective etching is used to form the waveguide trench 10', the sidewall of the waveguide trench 10' generally does not have a strictly specific crystal orientation, and the smoothness of the sidewall is not as good as using sele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com