PVC (polyvinyl chloride) stabilizer for injection molding and preparation method thereof

A stabilizer and auxiliary stabilizer technology, which is applied in the field of PVC stabilizer for injection molding and its preparation, can solve the problems of intolerant to vulcanization pollution, poisonous lead compounds, poor transparency, etc., achieve no dust pollution, improve product quality, and be easy to mold effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

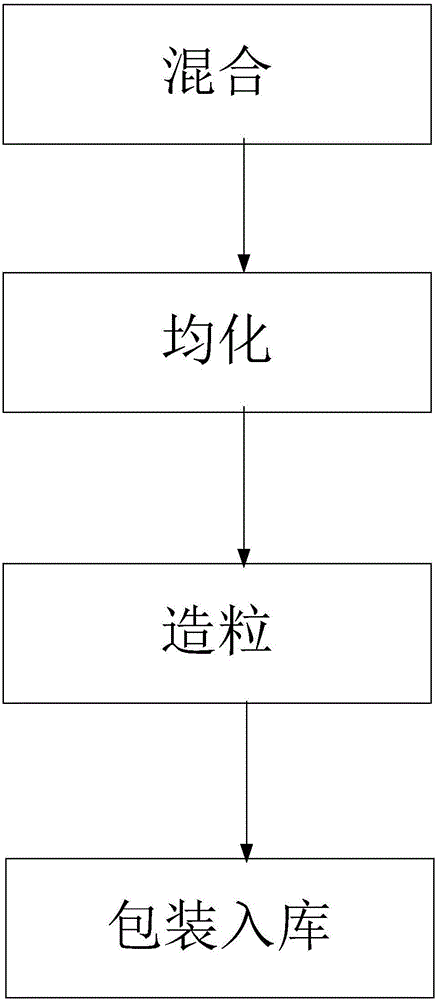

[0029] Such as figure 1 Shown, the preparation method of PVC stabilizer for injection molding of the present invention may further comprise the steps:

[0030] Step 1, 1%-19% of fatty acid salt, 2%-12% of auxiliary stabilizer, 23%-29% of zeolite, 12%-16% of lubricant, 13%-15% of phosphate, maleic acid Calcium 8%-10%, antioxidant 6%-20% are mixed in a mixing box to form a mixture;

[0031] Step 2, the mixture is homogenized;

[0032] Step 3, the homogenized raw materials are granulated by granulation equipment;

[0033] Step 4, packing and storage after granulation.

Embodiment 1

[0035] Mix 1% fatty acid salt, 12% auxiliary stabilizer, 29% zeolite, 16% lubricant, 15% phosphate, 10% calcium maleate, and 17% antioxidant in a mixing box to form a mixture material; Step 2, homogenize the mixture; Step 3, the homogenized raw material is granulated by granulation equipment; Step 4, granulated and packed into storage.

Embodiment 2

[0037] 19% of fatty acid salt, 2% of auxiliary stabilizer, 23% of zeolite, 12% of lubricant, 14% of phosphate, 10% of calcium maleate, and 20% of antioxidant are mixed in a mixing box to form a mixture ; Step 2, homogenizing the mixture; Step 3, granulating the homogenized raw materials through granulation equipment; Step 4, packaging and storing the granulated materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com