Nickel-based alloy with high wear resistance and manufacturing method thereof

A manufacturing method and technology of nickel-based alloys, applied in the field of alloys and nickel-based alloys, can solve the problems of low yield of zirconium elements, reduce the performance and use requirements of GH80A, and achieve the effect of retaining comprehensive properties and eliminating stress effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to describe the technical content of the present invention more clearly, further description will be given below in conjunction with specific embodiments.

[0018] The invention provides a nickel-based alloy with high wear resistance, wherein the alloy comprises: 1%-1.8% of aluminum, 1.8%-2.7% of titanium, cobalt≤2.0%, iron ≤1.5%, chromium is 18%-21%, manganese ≤0.4%, and the balance is nickel and other unavoidable impurity elements in the smelting process.

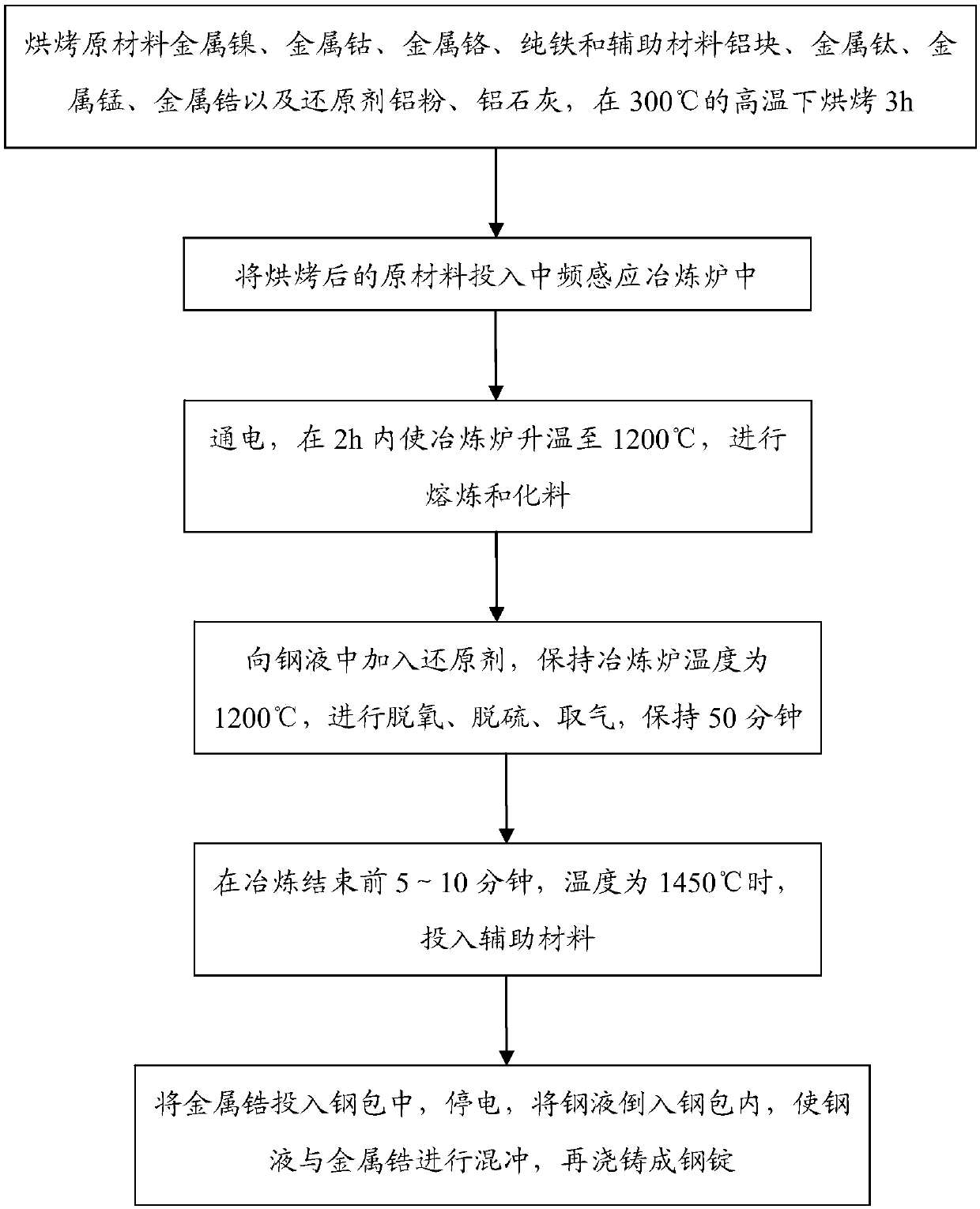

[0019] The present invention also provides a method for manufacturing a nickel-based alloy with high wear resistance, wherein the method mainly includes the following steps:

[0020] (1) Bake the raw material nickel metal, cobalt metal, chromium metal, pure iron and auxiliary materials aluminum block, titanium metal, manganese metal, zirconium metal, reducing agent aluminum powder, aluminum lime, and bake at a high temperature of 300 ° C for 3 hours;

[0021] (2) Putting the raw material nickel metal, cob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com