Whole corn powder and preparation method thereof

A technology of whole corn flour and corn, applied in the field of food processing, can solve the problems of losing whole grain flour, low GI application value, etc., and achieve the effects of reducing fat content, improving the composition of healthy components, and avoiding high GI value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

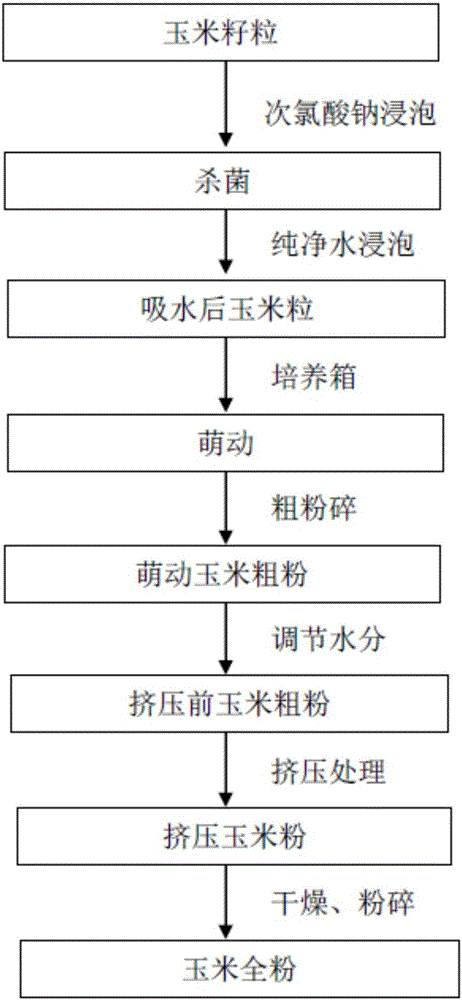

Method used

Image

Examples

Embodiment 1

[0036] (1) Take 5000g corn kernels, select, remove moldy and broken kernels, remove impurities in the corn kernels, soak in 0.4% sodium hypochlorite solution for 40min, sterilize, then wash 3 times with distilled water to avoid sodium hypochlorite residues;

[0037] (2) Add pure water and soak for 8 hours at 25°C;

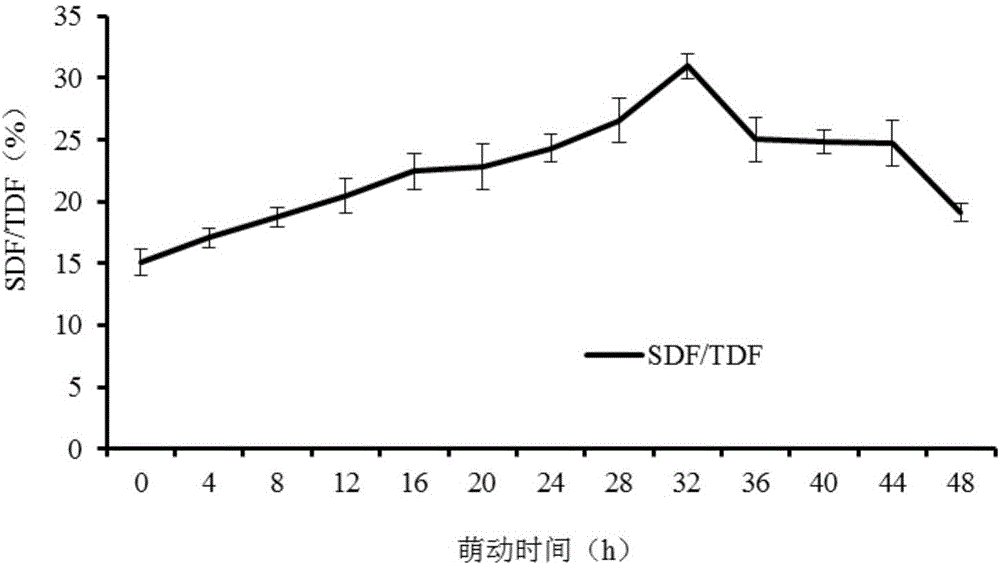

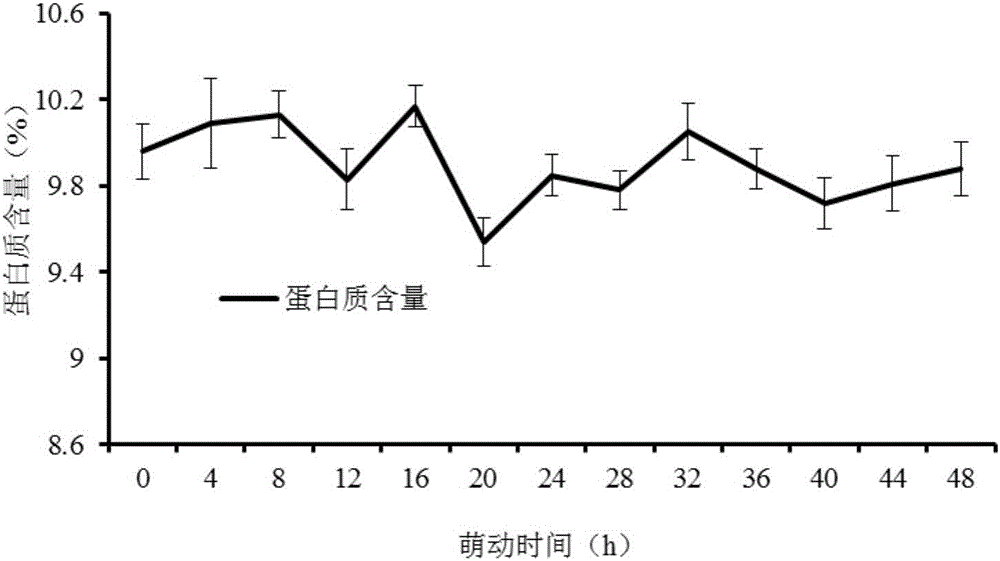

[0038] (3) Spread the soaked corn evenly in a germination tray that has been sterilized and covered with a filter cloth at the bottom, and place it in a constant temperature and humidity incubator with a temperature of 16°C and a humidity of 70%-80%, and carry out under the condition of no light. During the cultivation and germination process, the temperature and humidity were kept constant, no water was added to the germination tray, and the cultivation time was 0-48 hours to obtain germinated corn kernels, and no obvious corn sprouts were seen.

[0039] (4) Coarsely pulverize the germinated corn kernels with a fineness of 40-80 meshes; determine the dietary fiber...

Embodiment 2

[0041] (1) Take 5000g corn kernels, select, remove moldy and broken kernels, remove impurities in the corn kernels, soak in 0.4% sodium hypochlorite solution for 40min, sterilize, then wash 3 times with distilled water to avoid sodium hypochlorite residues;

[0042] (2) Add pure water and soak for 8 hours at 25°C;

[0043] (3) Spread the soaked corn evenly in a germination tray that has been sterilized and covered with a filter cloth at the bottom, and place it in a constant temperature and humidity incubator with a temperature of 16°C and a humidity of 70%-80%, and carry out under the condition of no light. Cultivate, during the cultivation process, keep the temperature and humidity constant, do not add water to the germination tray, and cultivate for 32 hours to obtain germinated corn kernels, no obvious corn sprouts grow, and there is no raw green smell;

[0044] (4) Coarsely pulverizing the germinated corn kernels with a fineness of 40-80 mesh;

[0045] (5) adding the coa...

Embodiment 3

[0059] (1) Take 8000g corn kernels, select, remove moldy and broken kernels, remove impurities in the corn kernels, soak in 0.5% sodium hypochlorite solution for 30 minutes, sterilize, then wash 3 times with distilled water to avoid sodium hypochlorite residues;

[0060] (2) Add pure water and soak for 7 hours at 28°C;

[0061] (3) Spread the soaked corn evenly in a germination tray that has been sterilized and covered with a filter cloth at the bottom, and place it in a constant temperature and humidity incubator with a temperature of 18°C and a humidity of 70%-80%, and carry out under the condition of no light. Cultivate, during the germination process, keep the temperature and humidity constant, do not add water to the germination tray, and cultivate for 28 hours to obtain germinated corn kernels without green taste;

[0062] (4) Coarsely pulverizing the germinated corn kernels with a fineness of 40-80 mesh;

[0063] (5) adding coarse corn flour to purified water to adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com