Gastric-juice-soluble capsule shell and preparation method thereof

A capsule shell and stomach-dissolving technology, which is applied in the field of stomach-soluble capsule shell and its preparation, can solve the problems of being easily degraded by enzymes, and achieve the effects of easy purification, easy-to-obtain raw materials, and good cell compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

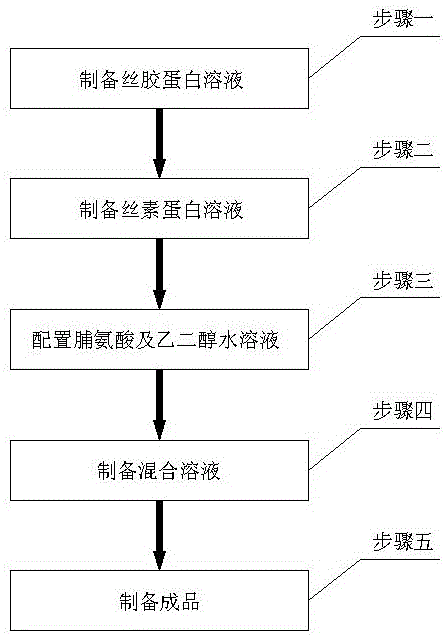

[0027] A method for preparing a stomach-soluble capsule shell, comprising the following steps: Step 1: preparing a sericin solution; Step 2: preparing a silk fibroin solution; Step 3: preparing an aqueous solution of proline and ethylene glycol; Step 4: preparing a mixed Solution; step five: preparing finished product;

[0028] in:

[0029] Step 1: Using silkworm cocoon shells or silkworm raw silk as raw materials, add deionized water to boil the cocoons in a boiling water bath, centrifuge and take the supernatant to obtain a sericin solution, measure its mass percentage concentration, and refrigerate in the refrigerator for later use;

[0030] Step 2: Use silkworm cocoon shells or silkworm raw silk as raw materials, degumming to remove sericin, drying, dissolving with lithium bromide, dialyzing in deionized water for 2 to 5 days at 4°C to obtain a silk fibroin solution, and measuring its mass percentage Concentration, refrigerated in the refrigerator for later use;

[0031]...

Embodiment 1

[0038] Step 1, boil the cleaned silkworm cocoons and deionized water in a ratio of 1:10 in a high temperature and high pressure sterilizing pot for 20 minutes, filter the cocoon shells to obtain a sericin solution;

[0039] Step 2: Degumming silkworm cocoons with sodium bicarbonate-sodium carbonate buffered aqueous solution, washing and drying the silkworm cocoons to obtain degummed silk. According to the degummed silk: lithium bromide solution (9.3mol / L) = 1:20 to dissolve the degummed silk, the mixed solution is dialyzed with deionized water at 4°C for 3~4 days to obtain the silk fibroin solution;

[0040] Step 3: Take ethylene glycol and proline, and configure it into an aqueous solution of proline and ethylene glycol for subsequent use;

[0041] Step 4: Mix the solutions of silk fibroin, sericin, ethylene glycol and proline into the mold according to the mass ratio of 2:88:8:2;

[0042] Step 5: Put the mixed solution in an oven at 75°C for 1 hour, and then place it in a c...

Embodiment 2

[0045] Step 1, steaming the cleaned silkworm cocoon and deionized water in a high temperature and high pressure sterilizing pot for 1 hour at a ratio of 1:20, filtering the cocoon shell to obtain a sericin solution;

[0046] Step 2: Degumming silkworm cocoons with sodium bicarbonate-sodium carbonate buffered aqueous solution, washing and drying the silkworm cocoons to obtain degummed silk. According to the degummed silk: lithium bromide solution (9.3mol / L) = 1:10 to dissolve the degummed silk, the mixed solution is dialyzed with deionized water at 4°C for 3~4 days to obtain the silk fibroin solution;

[0047]Step 3: Take ethylene glycol and proline, and configure it into an aqueous solution of proline and ethylene glycol for subsequent use;

[0048] Step 4: Mix the solutions of silk fibroin, sericin, ethylene glycol and proline into the mold according to the mass ratio of 13:77:9:1;

[0049] Step 5: Put the mixed solution in an oven at 75°C for 2 hours, and then put it into a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com