Covalent organic polymer for methane adsorption and storage and preparation method thereof

A covalent organic and polymer technology, applied in separation methods, mechanical equipment, chemical instruments and methods, etc., can solve the problems of poor thermal stability and water stability, limit large-scale industrial applications, and unfavorable environmental protection, etc., and achieve low Effects of skeleton density, good hydrothermal and chemical stability, broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

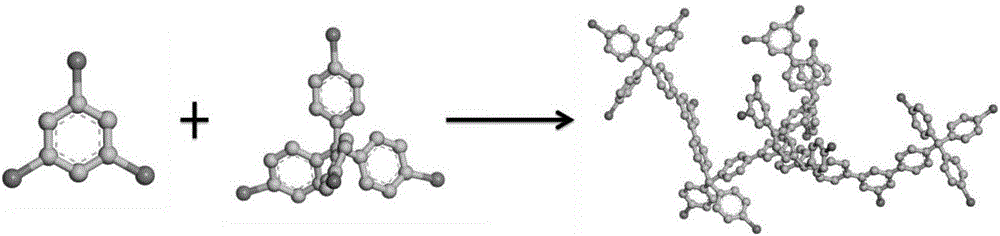

Method used

Image

Examples

Embodiment 1

[0029] First, dissolve 0.432g of bis-(1,5-cyclooctadiene)nickel ([Ni(cod)2]) in 30mL of DMF solution, stir until completely dissolved, then add 0.246g of 2,2'-bipyridine and 0.192ml of 1,5-cyclooctadiene (cod) were added to the mixture and stirred for about 30 minutes, then 0.1065g of TBM and 0.07g of XTBB were added into the solution, and the reaction was stirred at 85°C for 10 hours. After cooling, add an appropriate amount of concentrated hydrochloric acid until the medium solution turns transparent green, filter with CHCl 3 (5×15mL), THF (5×15mL) and H 2 O (5 x 15 mL) washes. The filtered sample was then vacuum dried at 120° C. for 24 hours. This sample was named COP-10. The experimental characterization results are as follows:

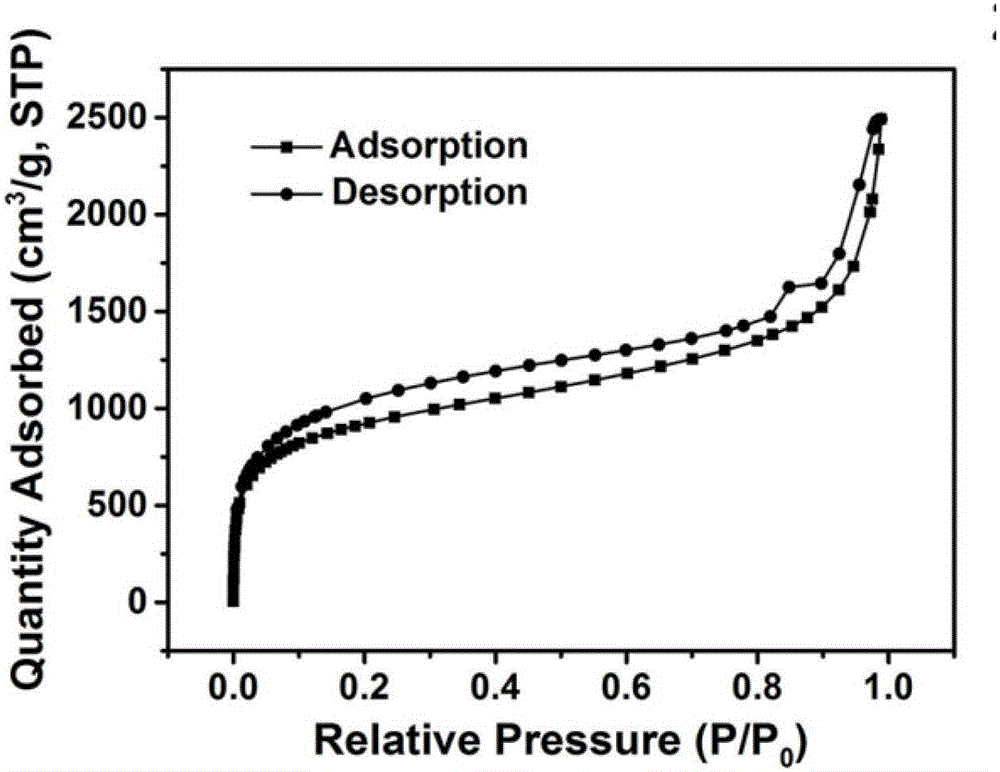

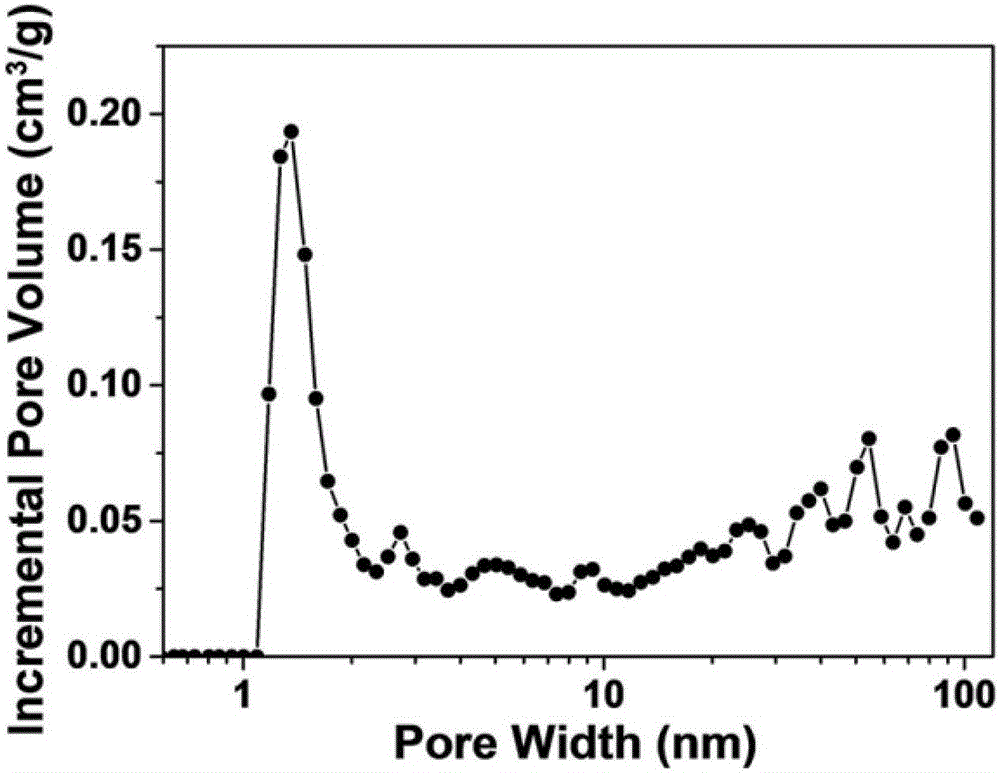

[0030] COP-10 was degassed at 180°C for 8 hours, and then ASAP 2020 was used for specific surface area and pore size analysis. figure 2 is the nitrogen adsorption curve of COP-10, at P / P 0 When image 3 The results are consistent. The pore ...

Embodiment 2

[0035] First, dissolve 0.324g of bis-(1,5-cyclooctadiene)nickel ([Ni(cod)2]) in 30mL of DMF solution, stir until completely dissolved, then add 0.184g of 2,2'-bipyridine 0.144ml of 1,5-cyclooctadiene (cod) was added to the mixture and stirred for about 30 minutes, then TBM and XTBB were added to the solution, and the reaction was stirred at 100°C for 1.5 hours using microwave method. After cooling, add concentrated hydrochloric acid until the medium solution turns transparent green, filter with CHCl 3 (5×15mL), THF (5×15mL) and H 2 O (5 x 15 mL) washes. The filtered sample was then vacuum dried at 120° C. for 24 hours.

[0036] According to the analysis and test method in Example 1, it is determined that the covalent organic polymer of the present invention has a methane adsorption capacity of 300 V / V at ambient temperature (25° C.) and 6.0 MPa.

Embodiment 3

[0038] First, bis-(1,5-cyclooctadiene)nickel ([Ni(cod)2], 1.125g, 4.09mmol) was dissolved in 65mL DMF solution, stirred until completely dissolved, and then 2,2'-linked Pyridine (0.640 g, 4.09 mmol) and 1,5-cyclooctadiene (cod, 0.50 mL, 3.96 mmol) were added to the mixture and stirred for approximately 30 minutes, then TBM and XTBB were added to the solution. Using the supergravity method, the rotating speed of the packed bed rotor was 2000r / min, and the reaction was stirred at 80°C for 1 hour. After cooling, add concentrated hydrochloric acid until the medium solution turns transparent green, filter with CHCl 3 (5×15mL), THF (5×15mL) and H 2 O (5 x 15 mL) washes. The filtered sample was then vacuum dried at 120° C. for 24 hours.

[0039] According to the analysis and test method in Example 1, it is determined that the covalent organic polymer of the present invention has a methane adsorption capacity of 300 V / V at ambient temperature (25° C.) and 6.0 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com