Au@MnPS catalyst as well as preparation method and use thereof

A catalyst and application technology, applied in the field of Au@MnPS catalyst and its preparation and application, can solve the problem of no olefin oxidation, etc., and achieve the effect of good conversion rate and selectivity, and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

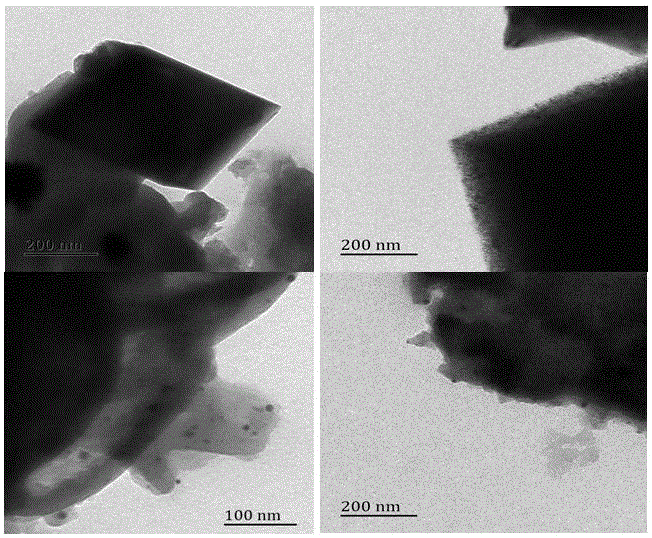

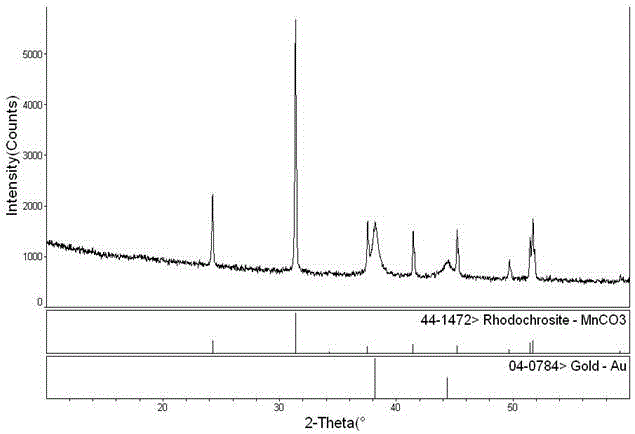

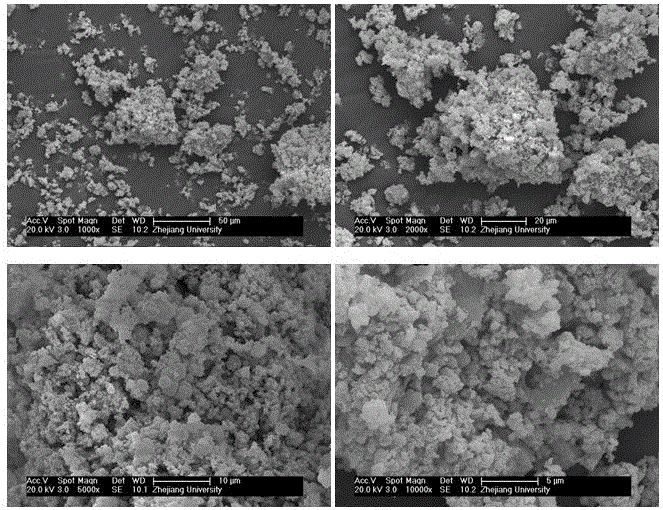

[0024] Preparation of Au@MnPS catalyst:

[0025] 3. Dissolve 8625g of vanillin in 50 mL of propionic acid, reflux at 141°C, slowly add 1.3 mL of pyrrole dropwise, and react for 45 minutes. Cool to room temperature, filter with suction, and wash several times with anhydrous methanol. The obtained purple-red solid was dried at 110° C. for 2 hours; 0.2415 g of the obtained porphyrin and 1.2255 g of manganese acetate were dissolved in DMF and put into a hydrothermal synthesis kettle. After reacting at 180° C. for 48 h, cool to room temperature, filter with suction, and wash with deionized water to obtain a black block of MnPS solid, which is ground to powder. Get the black solid 0.5g that above-mentioned steps obtains, add urea 0.9g in the there-necked flask, add different amounts of chloroauric acid solution (HAuCl 4 4H 2 O, the concentration is 0.1g / L), diluted to 30mL with deionized water. After stirring and reflux at 80°C for 6h, add 30mL of commercially available formalde...

Embodiment 2

[0029] Catalyst activity evaluation. Gold content 2% Au@MnPS catalyst 0.10 g was placed in a PTFE-lined autoclave (volume = 20 mL), 0.8215 g of cyclohexene, solvent acetonitrile 10 mL, TBHP initiator 5 drops, and molecular oxygen as an oxidant at 1 MPa The reaction was stirred at 80°C for 20 hours under pressure. The conversion rate that obtains cyclohexene oxidation is 45.047%, the selectivity of epoxy cyclohexane is 68.406%, the selectivity of cyclohexenol is 12.502%, the selectivity of cyclohexenone is 12.675%, and the selectivity of o-cyclohexanedi The selectivity of alcohol is 6.416%.

Embodiment 3

[0031] Catalyst activity evaluation. A gold content of 2% Au@MnPS catalyst 0.10 g was used for the reaction. 0.8215g of cyclohexene, solvent acetonitrile 10mL, 5 drops of TBHP initiator, and molecular oxygen as an oxidizing agent were stirred and reacted at 80° C. for 5 hours under a pressure of 1 MPa. The conversion rate that obtains cyclohexene oxidation is 39.667%, the selectivity of epoxy cyclohexane is 52.966%, the selectivity of cyclohexenol is 9.566%, the selectivity of cyclohexenone is 10.827%, and the selectivity of o-cyclohexanedi The selectivity of alcohol is 26.641%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com