Manufacturing method of high-density lanthanum chromate ceramic heating unit

A ceramic heating element and a manufacturing method technology, which are applied to electric heating devices, heating element materials, ohmic resistance heating, etc., can solve the problems of low yield, rough appearance of the heating element, low strength of the heating element, etc. The effect of good appearance quality and high product strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] A method for manufacturing a high-density lanthanum chromate ceramic heating element specifically includes the following steps:

[0012] (1) Preparation of La 0.8 Ca 0.2 CrO 3 Lanthanum chromate ceramic powder;

[0013] (2) The prepared La 0.8 Ca 0.2 CrO 3 The ceramic powder is loaded into a graphite mold, put into a hot-pressing sintering furnace, and hot-pressed to form a lanthanum chromate ceramic heating element in a vacuum or argon protection environment. The hot-pressing temperature is 1600°C, the molding pressure is 35MPa, and the temperature is kept for 3 hours.

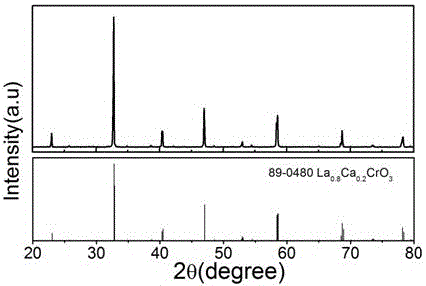

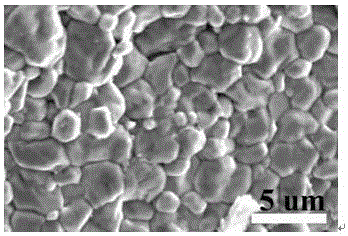

[0014] High-purity lanthanum chromate ceramics can be obtained through the above process, and the X-ray diffraction pattern is shown in the attachment figure 1 . The heating element has good appearance quality, no macro defects such as cracks and cracks, and the surface is smooth and no pitting; the relative density is 98.5%, the structure is dense, and there is no internal porosity. The microstructure photo ...

Embodiment 2

[0016] A method for manufacturing a high-density lanthanum chromate ceramic heating element specifically includes the following steps:

[0017] (1) Preparation of La 0.98 Ca 0.02 CrO 3 Lanthanum chromate ceramic powder;

[0018] (2) The prepared La 0.98 Ca 0.02 CrO 3 The ceramic powder is loaded into a graphite mold, and placed in a hot-pressing sintering furnace to form a lanthanum chromate ceramic heating element under vacuum or argon protection. The hot-pressing temperature is 1700°C, the molding pressure is 30MPa, and the heat preservation and pressure are maintained for 2 hours.

[0019] High-purity lanthanum chromate ceramics can be obtained through the above process. The heating element has good appearance quality, no macro defects such as cracks and cracks, smooth surface and no pitting; the relative density is 98.8%, the structure is dense, and there is no internal porosity.

Embodiment 3

[0021] A method for manufacturing a high-density lanthanum chromate ceramic heating element specifically includes the following steps:

[0022] (1) Preparation of La 0.92 Ca 0.08 CrO 3 Lanthanum chromate ceramic powder;

[0023] (2) The prepared La 0.92 Ca 0.08 CrO 3 The ceramic powder is loaded into a graphite mold, and placed in a hot-pressing sintering furnace to form a lanthanum chromate ceramic heating element under a vacuum or argon protection environment. The hot-pressing temperature is 1850°C, the forming pressure is 25MPa, and the heat preservation and pressure are maintained for 0.5 hours.

[0024] High-purity lanthanum chromate ceramics can be obtained through the above process. The heating element has good appearance quality, no macro defects such as cracks and cracks, smooth surface and no pitting; the relative density is 99.2%, the structure is dense, and there is no internal porosity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com