Technique and device for synthesizing methyl chlorosilane

The technology of methyl chlorosilane and process is applied in the field of simple devices for evaluating the reaction conditions of methyl chlorosilane, can solve the problems of large device investment, complicated operation, long process flow, etc., and achieves accurate experimental conclusion, good temperature stability, slow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

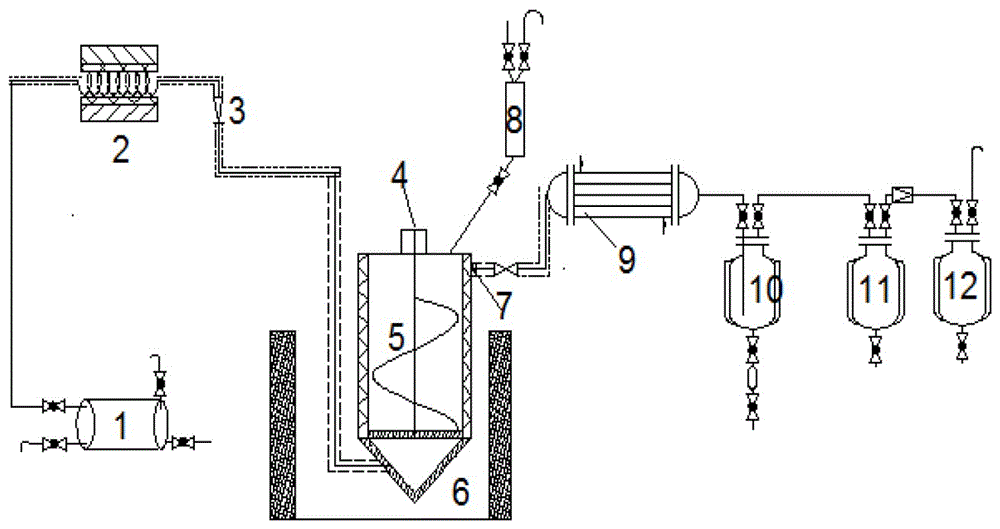

Method used

Image

Examples

Embodiment 1

[0028] Turn on the sand bath temperature control device to raise the temperature in the stirred bed reactor to a set 360°C; mix silicon powder and catalyst (the catalyst is composed of a main catalyst and a co-catalyst, wherein the main catalyst is a ternary copper mixture, that is, a simple substance The mixture of copper powder, cupric oxide and cuprous oxide, elemental copper accounts for 50% by weight percentage, cupric oxide 30%, cuprous oxide 20%; Described cocatalyst is made up of zinc powder, tin powder, and zinc powder accounts for about 8% of the mass of the main catalyst, and tin powder accounts for 1% of the mass of the main catalyst.) Mix evenly at 50:1 (the particle size of the silicon powder is 30 μm), send it into the stirring bed through the feeding device, and start the magnetic stirring; take it from the industrial device The returned methyl chloride enters the stirred bed with a flow rate of 2L / h after being vaporized by the methyl chloride vaporizer, and th...

Embodiment 2

[0030] Other implementation conditions are the same as 1, when reaction temperature is 400 DEG C, silicon powder and catalyzer (the described catalyzer is made up of procatalyst and cocatalyst, wherein, procatalyst is ternary copper mixture, i.e. elemental copper powder, copper oxide and The mixture of cuprous oxide, elemental copper accounts for 30% by weight percentage, cupric oxide 40%, cuprous oxide 30%; Described cocatalyst is made up of zinc powder, tin powder, and zinc powder accounts for about 5% of main catalyst mass , tin powder accounted for 0% of the mass of the main catalyst.) According to 80:1 mixed evenly (silicon powder particle size is 50μm), the product component content is as follows: monomethyltrichlorosilane 49.073%, dimethyldichlorosilane 36.013% , trimethylchlorosilane 3.292%, other 11.622%.

Embodiment 3

[0032] Other implementation conditions are the same as 1. When the reaction temperature is 300°C, the product component content is as follows: 45.989% of monomethyltrichlorosilane, 42.117% of dimethyldichlorosilane, 4.518% of trimethylmonochlorosilane, and 7.376% of others .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com