LED-UV printing ink and preparation method and using method thereof

A technology of ink and urethane acrylate, which is applied in the direction of ink, application, household appliances, etc., can solve the problems affecting the performance of the processed workpiece, the temperature of the processed workpiece increases, and the power requirement is getting higher and higher, so as to achieve no need for preheating and Cool down time, reduce emissions, both economic and environmental effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

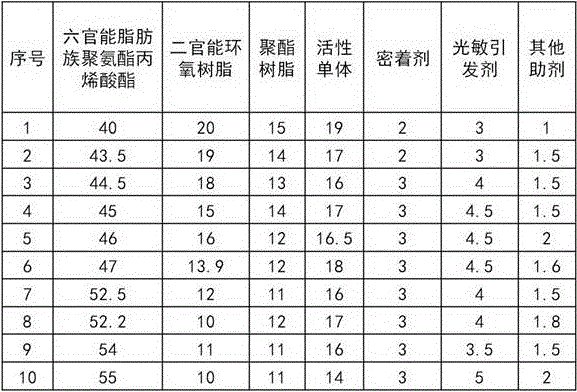

Method used

Image

Examples

preparation example Construction

[0035] 1. Preparation of hexafunctional aliphatic urethane acrylate

[0036] Put dipentaerythritol and zinc stearate into the reaction container, stir evenly and heat until the temperature reaches 55°C, keep the temperature, drop in isophorone diisocyanate at a uniform speed, keep the temperature and continue to stir the reaction until the -NCO mass fraction test is less than 15% . In this step, the molar mass ratio of dipentaerythritol to isophorone diisocyanate is 1:6.15, and the mass of zinc stearate is 0.035% of the sum of the mass of dipentaerythritol and isophorone diisocyanate. Zinc stearate is added as a catalyst and a heat stabilizer in this step, which not only promotes the occurrence of the reaction but also effectively maintains the reaction speed and prevents violent polymerization of the product. -NCO content was determined by the di-n-butylamine method.

[0037] Drop in hydroxyethyl acrylate with the same molar mass as isophorone diisocyanate at a constant spe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com