Preparation method of bionic oil-water separation copper foam

A technology of copper foam and bionic oil, applied in the field of bionic science, can solve the problems of complex processing steps, easy to be polluted, long processing time, etc., achieve good mechanical stability and reusable properties, controllable experimental parameters, and high-efficiency oil-water separation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A preparation method of bionic oil-water separation copper foam, the specific preparation method is as follows:

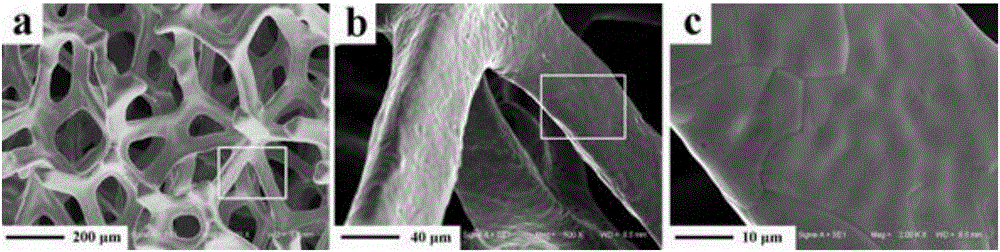

[0021] 1) Pretreatment of the copper foam: Place the copper foam in dilute hydrochloric acid, acetone and distilled water for 10 minutes for ultrasonic cleaning to remove the oxide film and dirt on the surface;

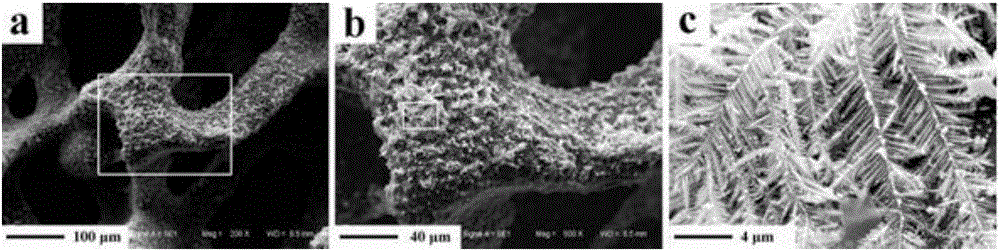

[0022] 2) Oxidation deposition: immerse the cleaned copper foam in the electroplating solution for electrolysis, the electroplating solution is AgNO 3 , the concentration is 0.02M / L, the volume of the reaction solution is 250ml, and the reaction time is 30s. After the replacement reaction is completed, a microstructure of pine needles is formed on the surface of the copper foam, that is, a bionic micro-nano scale double-layer hierarchical structure is formed on the copper foam substrate. surface;

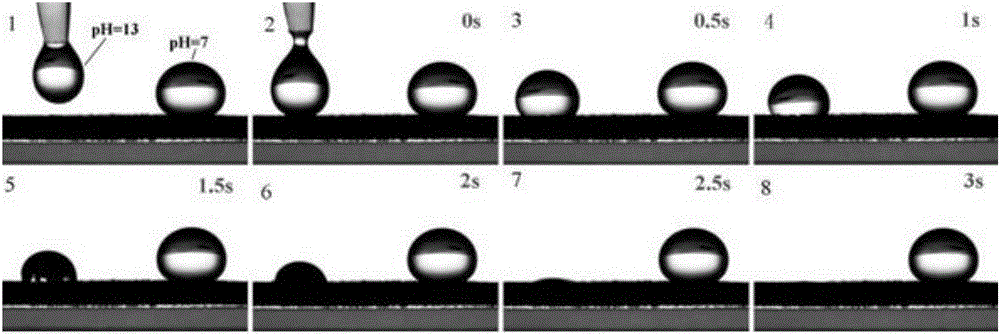

[0023] 3) Surface modification: soak the copper foam with biomimetic micro-nano double-layer hierarchical structure into n-dodecyl mercaptan (HS(CH 2 )...

Embodiment 2

[0026] A preparation method of bionic oil-water separation copper foam, the specific preparation method is as follows:

[0027] 1) Pretreatment of the copper foam: Place the copper foam in dilute hydrochloric acid, acetone and distilled water for 10 minutes for ultrasonic cleaning to remove the oxide film and dirt on the surface;

[0028] 2) Oxidation deposition: immerse the cleaned copper foam in the electroplating solution for electrolysis, the electroplating solution is AgNO 3 , the concentration is 0.03M / L, the volume of the reaction solution is 200ml, and the reaction time is 20s. After the replacement reaction is completed, a microstructure of pine needles is formed on the surface of the copper foam, that is, a bionic micro-nano scale double-layer hierarchical structure is formed on the copper foam substrate. surface;

[0029] 3) Surface modification: soak the copper foam with biomimetic micro-nano double-layer hierarchical structure into n-dodecyl mercaptan (HS(CH 2 )...

Embodiment 3

[0032] A preparation method of bionic oil-water separation copper foam, the specific preparation method is as follows:

[0033] 1) Pretreatment of the copper foam: Place the copper foam in dilute hydrochloric acid, acetone and distilled water for 10 minutes for ultrasonic cleaning to remove the oxide film and dirt on the surface;

[0034] 2) Electrochemical deposition: immerse the cleaned copper foam in the electroplating solution for electrolysis, the electroplating solution is AgNO 3 , the concentration is 0.04M / L, the volume of the reaction solution is 150ml, and the reaction time is 15s. After the replacement reaction is completed, a microstructure of pine needles is formed on the surface of the copper foam, that is, a bionic micro-nano scale double-layer hierarchical structure is formed on the copper foam substrate. surface;

[0035] 3) Surface modification: soak the copper foam with biomimetic micro-nano double-layer hierarchical structure into n-dodecyl mercaptan (HS(C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com