A kind of preparation method of wear-resistant superhydrophobic film

A super-hydrophobic and thin-film technology, applied in the direction of electrolytic inorganic material coating, electrolytic coating, electrophoretic plating, etc., can solve the problems of damage, limited heat resistance, and matrix damage, and achieve low facility requirements, low material cost, and combined strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] A preparation method of wear-resistant super-hydrophobic film, comprising the following steps:

[0021] 1) After the metal substrate is polished to 600 mesh by sandpaper, it is taken out after ultrasonication in ethanol for 10 minutes, washed and dried by tap water and deionized water, and then put into a constant temperature drying oven at 60°C for use;

[0022] 2) Measure 50mL of ethanol, 0.2M NaNO 3 After mixing, add 5 mL of tetraethyl orthosilicate, adjust the pH of the solution to about 4.5, and stir it magnetically for 12 hours before use.

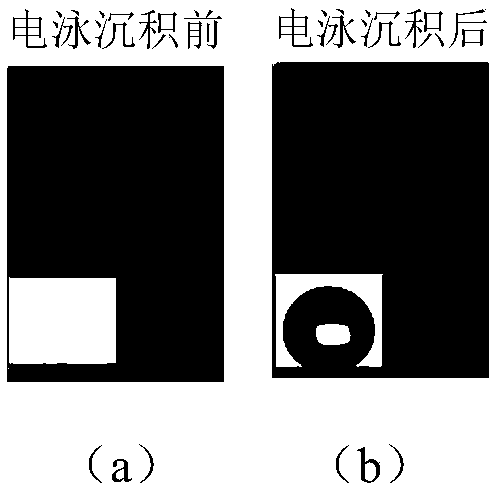

[0023] 3) Using a three-electrode system to electrodeposit a layer of SiO on the metal with high mechanical strength, good bonding force, and a highly porous structure 2 Thin film, wherein the working electrode is a metal substrate, Pt sheet and Ag / AgCl (saturated KCl) electrode are used as counter electrode and reference electrode respectively, the applied potential is -1.0V~-2.0V, and the electrodeposition time is 200~600s...

Embodiment 1

[0029] The substrate is a commercial aluminum alloy substrate AA2024-T3, which is sanded to 600 meshes, ultrasonicated in ethanol for 10 minutes, taken out, cleaned and dried with tap water and deionized water, and then placed in a constant temperature drying oven at 60°C for use.

[0030] Hydrophobic SiO 2 Preparation of powder:

[0031] Solution 1 composition: weigh 1g nano-SiO 2 The powder is dispersed in a solution of 100mL pH=8, wherein the control of the pH of the solution is adjusted by ammonia water, and it is used after magnetic stirring for 1 hour; the composition of solution 2: disperse 5mL of dodecyltrimethoxysilane in 100mL of ethanol, magnetic After stirring for 1 h, set aside. The above-mentioned solution 2 was added dropwise to the solution 1, and a uniform suspension was formed after magnetic stirring for 6 hours, and aged for 4 hours for later use. After centrifugation (the rotation speed is controlled at 10000r / min, and the separation time is 10min), the ...

Embodiment 2

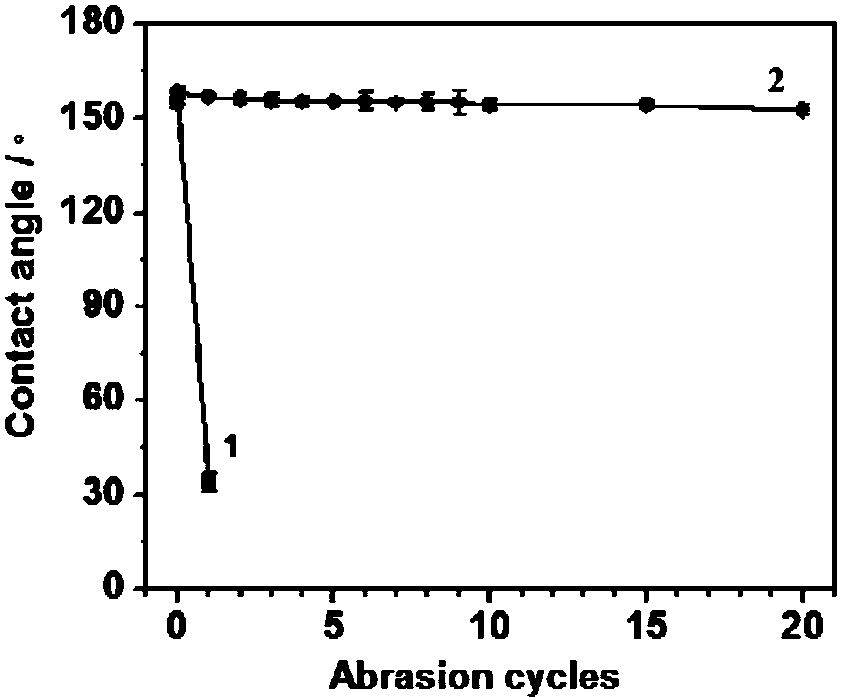

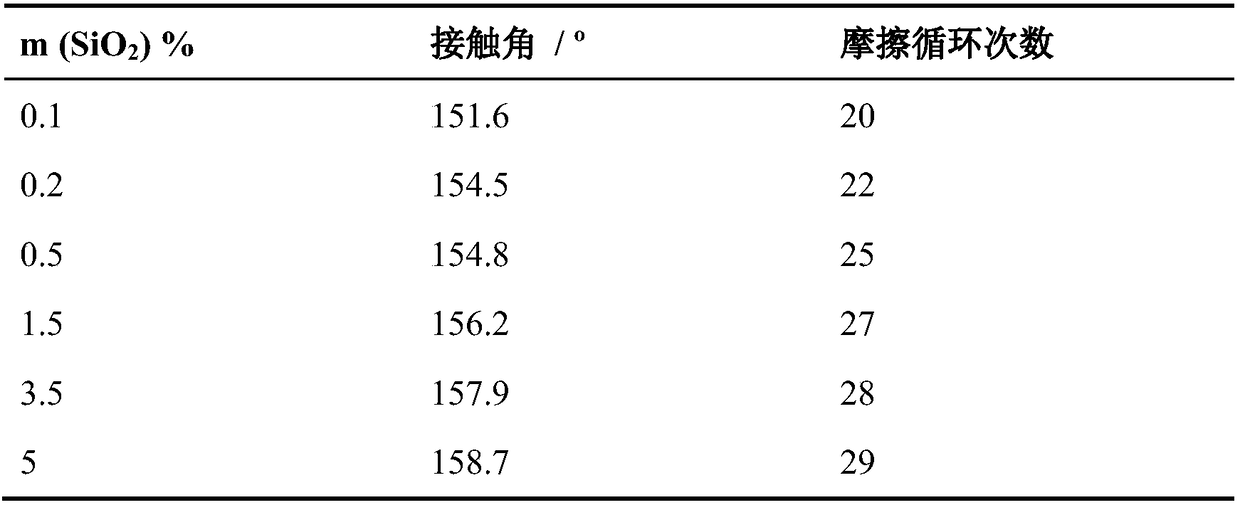

[0038] Other steps in this example are similar to Example 1, still using aluminum alloy as the substrate, but electrodepositing SiO 2 The deposition potential of the film is -2.0V, and the deposition time is 200s. Under the above process conditions, a friction test that can withstand ~20 cycles can also be obtained, and the contact angle of the sample is always maintained at about 159°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com