One-side water-repellent and one-side water-absorbent fabric and its processing technology

A processing technology, single-sided technology, applied in the field of textile and clothing, can solve the problems of heavy fabrics that can only be used in autumn and winter clothing fabrics, low ventilation effect, long production cycle, etc., to achieve good hand feeling, low manufacturing cost, and high production efficiency. short cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

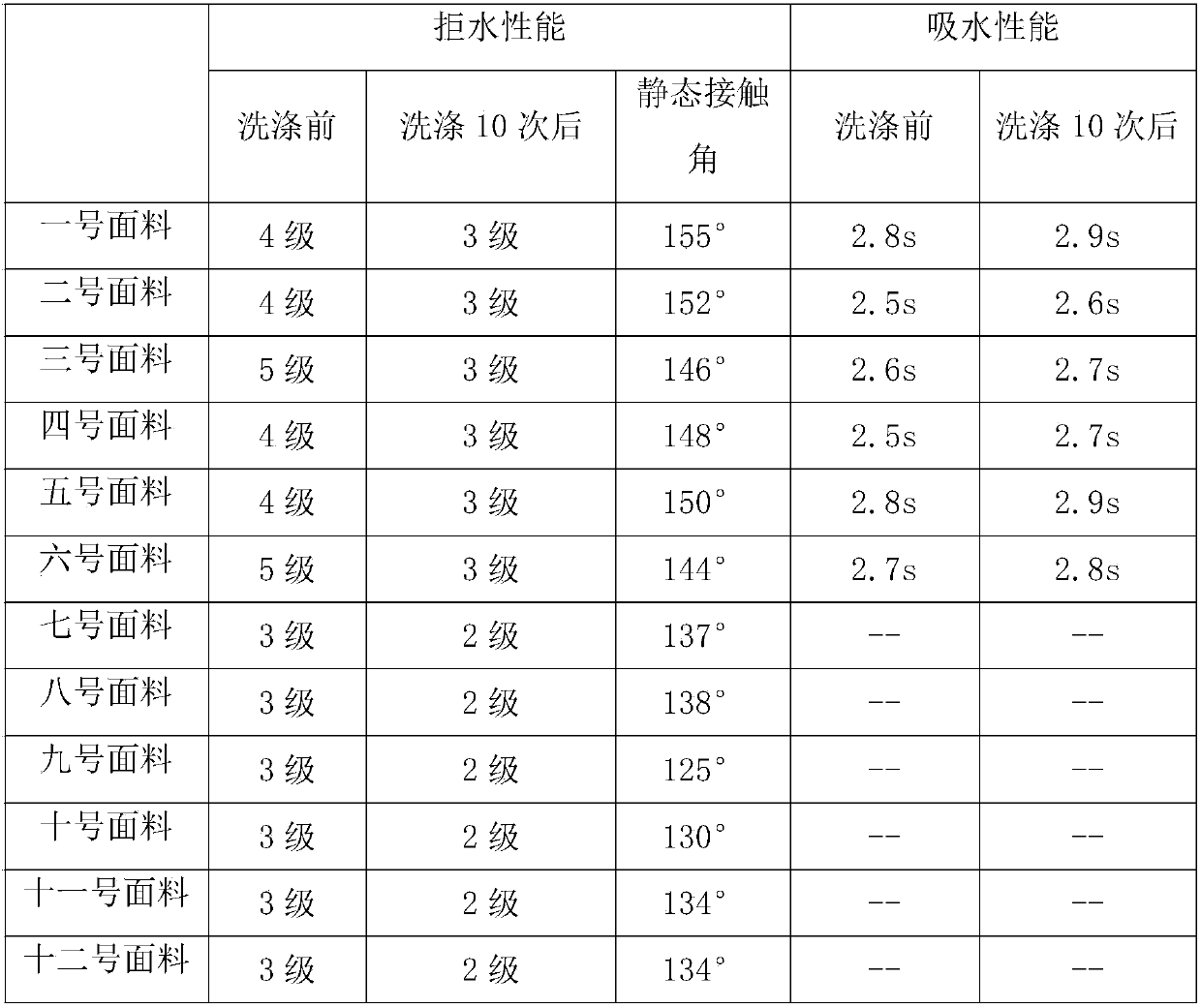

Embodiment 1

[0025] The woven fabric base fabric made of polyester fiber and its blended fibers is used as the raw material. The gram weight of the woven fabric base fabric is 60g / m2. The fibers on one side of the fabric have better water absorption effect. Viscose fiber or polyester fiber is added to the ester fiber, and the special-shaped section is used. After pre-treatment, dyeing and water absorption in the same bath, single-sided water-repellent processing and post-finishing, a fabric No. 1 is obtained. It has a water-absorbing layer and a water-repellent layer. Fibers with better water absorption are used, and the water-repellent layer is treated with water-repellent treatment.

[0026] The single-sided water-repellent processing and the post-finishing integrated processing include one dip, one rolling, drying, and baking. 160~180℃, the time is 120S, the proportion of each component of the water-repellent finishing agent used in single-sided water-repellent processing is: silicon-ba...

Embodiment 2

[0029] The non-woven fabric base fabric made of polyester fiber and its blended fibers is used as the raw material. The weight of the woven fabric base fabric is 80g / m2. Fabric No. 2 is obtained by integrated processing, which has a water-absorbing layer and a water-repellent layer, the water-absorbing layer is made of fibers with better water-absorbing effect, and the water-repellent layer is treated with water-repellent treatment.

[0030] The single-sided water-repellent processing and the post-finishing integrated processing include one dip, one rolling, drying, and baking. 150~170℃, the time is 80S, the proportion of each component of the water-repellent finishing agent used in single-sided water-repellent processing is: non-fluorine water-repellent agent 55g / l, cross-linking agent 10g / l, antistatic agent 10g / l l, citric acid 0.6g / l.

[0031] When absorbing water in the same bath for dyeing, the temperature is controlled at 50-80°C, and the treatment time is 10min.

Embodiment 3

[0033] The woven fabric base fabric made of polyester fiber and its blended fibers is used as the raw material. The weight of the woven fabric base fabric is 100g / m2. The fibers on one side of the fabric have better water absorption effect. Viscose fiber or polyester fiber is added to the ester fiber, and the special-shaped section is used. After pre-treatment, dyeing and water absorption in the same bath, single-sided water-repellent processing and post-finishing, the fabric No. 3 is obtained. It has a water-absorbing layer, a water-repellent layer, and a water-absorbing layer. Fibers with better water absorption are used, and the water-repellent layer is treated with water-repellent treatment.

[0034] The single-sided water-repellent processing and the post-finishing integrated processing include one dip, one rolling, drying, and baking. 150~180℃, the time is 50S, the proportion of each component of the water-repellent finishing agent used in single-sided water-repellent pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com