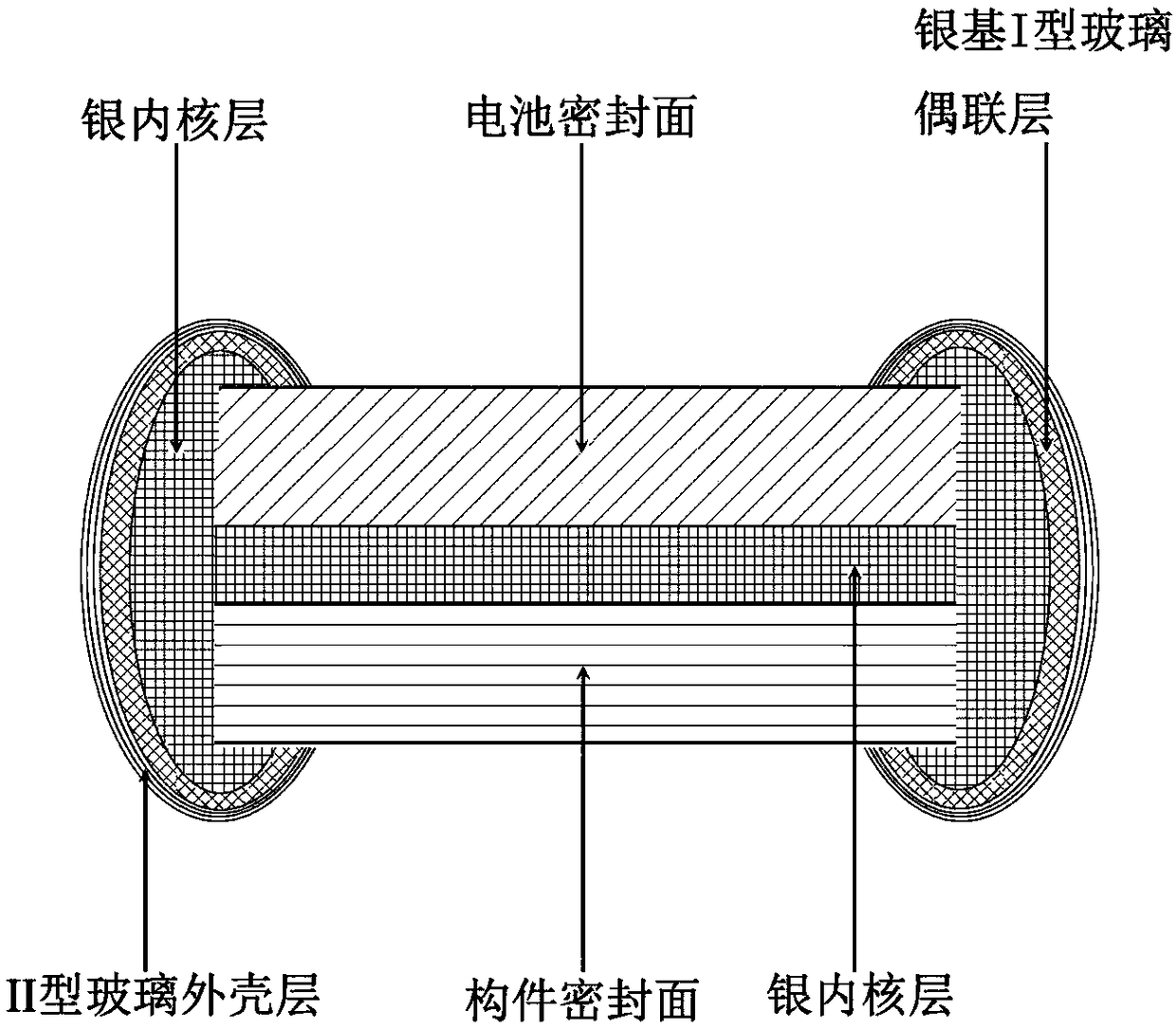

Composite sealing material for solid oxide fuel cell and battery sealing method

A solid oxide, fuel cell technology, used in solid electrolyte fuel cells, fuel cells, fuel cell components, etc., can solve the problem of not meeting the stable operation of SOFC, failing to meet electrical insulation requirements, and reducing sealing reliability, etc. problems, to achieve long-term operation stability and heat resistance cycle, overcome poor thermal stability and no electrical insulation, and prevent volatilization loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Composite sealing material preparation:

[0036] The distribution ratio of silver-based adhesive components: 75g of silver powder with a particle size range of 0.5-100 microns, 15g of bisphenol A epoxy resin, 6g of 1,4-butanediol glycidyl ether, and 3g of polymethylene polyphenyl polyisocyanate , 0.5g of 2-undecylimidazole, 0.5g of 3-aminopropyltrimethoxysilane;

[0037] Preparation of silver-based glue: first dissolve bisphenol A epoxy resin in 1,4-butanediol glycidyl ether and mix evenly, then add polymethylene polyphenyl polyisocyanate, 2-deca Monoalkylimidazole and 3-aminopropyltrimethoxysilane are mixed evenly; then silver powder is added to the above mixture, and mixed evenly to obtain silver-based glue, which is put into a container, airtight, and stored at low temperature for later use.

[0038]Raw material composition ratio of type I glass powder: SiO 2 35g, B 2 o 3 25g, BeO 15g, MgO 15g, CaO 10g;

[0039] Preparation of type I glass powder: Grinding or ...

Embodiment 2

[0061] Composite sealing material preparation:

[0062] The distribution ratio of silver-based adhesive components: 90g of silver powder with a particle size range of 0.5-100 microns, 5g of bisphenol F epoxy resin, 3g of 1,6-hexanediol diglycidyl ether, 1.5g of methylcyclohexyl diisocyanate, 2-ethyl-4-methylimidazole 0.5g;

[0063] The preparation of silver-based glue is the same as in Example 1.

[0064] Raw material composition ratio of type I glass powder: SiO 2 30g, B 2 o 3 30g, BeO 20g, MgO 10g, CaO 10g;

[0065] I type glass powder preparation, with embodiment 1.

[0066] Silver-based I-type glass composite adhesive composition ratio: 65g of silver powder with a particle size range of 0.5-100 microns, 15g of I-type glass powder, 6g of polyvinyl butyral, 10g of heptane, and 4g of paraffin oil;

[0067] The preparation of silver-based type I glass composite glue is the same as in Example 1.

[0068] Proportion of type II glass powder: SiO 2 35g, B 2 o 3 30g,A...

Embodiment 3

[0085] Composite sealing material preparation:

[0086] Distribution ratio of silver-based adhesive components: 75g of silver powder with a particle size range of 0.5-100 microns, 12g of bisphenol F epoxy resin, 10g of 1,4-butanediol glycidyl ether, and 2g of polymethylene polyphenyl polyisocyanate , 2-undecylimidazole 1g;

[0087] The preparation of silver-based glue is the same as in Example 1.

[0088] Raw material composition ratio of type I glass powder: SiO 2 25g, B 2 o 3 20g, BeO 20g, MgO 20g, CaO 15g;

[0089] I type glass powder preparation, with embodiment 1.

[0090] Silver-based type I glass composite adhesive composition ratio: 55g of silver powder with a particle size range of 0.5 to 100 microns, 30g of type I glass powder, 5g of ethyl cellulose, 8g of terpineol, and 2g of dimethyl phthalate;

[0091] The preparation of silver-based type I glass composite glue is the same as in Example 1.

[0092] Proportion of type II glass powder: SiO 2 35g, B 2 o 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com