Nickel-based catalyst, preparation method of nickel-based catalyst, reduction state nickel-based catalyst and method for preparing synthesis gas through methane auto-thermal reforming

A nickel-based catalyst and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc. cumbersome and other problems, to achieve good activity and stability, good catalytic performance, and good product repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

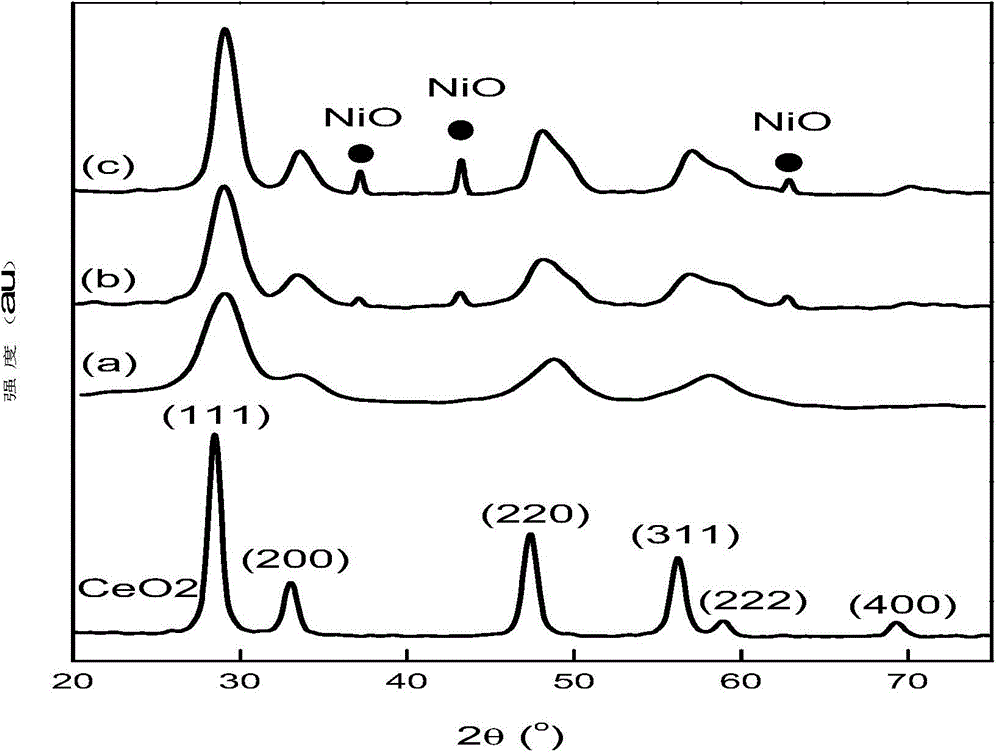

Image

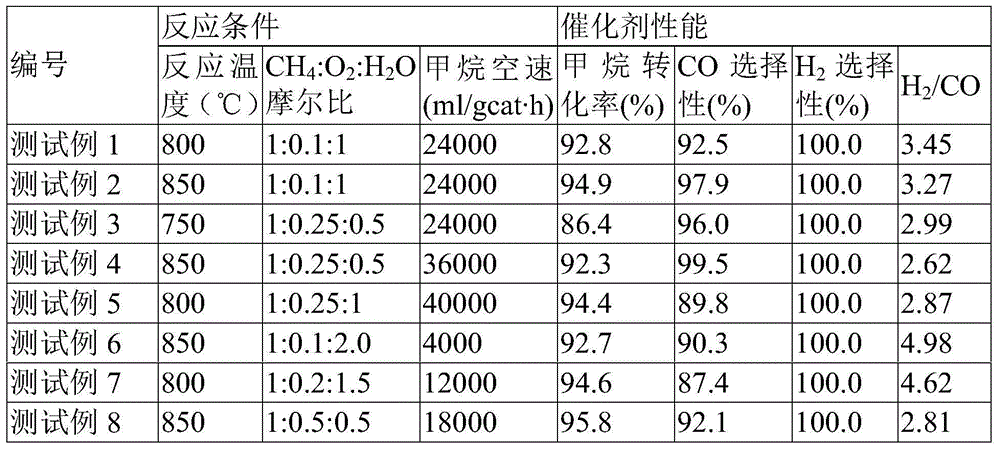

Examples

Embodiment approach

[0024] In a preferred embodiment of the present invention, in step (1), contact the precipitating agent and hydrogen peroxide with an aqueous solution containing cerium salt and zirconium salt, and adjust the pH of the obtained product to >7 before aging; preferably, pH=9-11.

[0025] According to the present invention, cheap and easy-to-obtain cerium salt that can be configured into an aqueous solution can be used in step (1). , preferably, the cerium salt is an inorganic cerium salt, preferably the cerium salt is at least one of cerium nitrate, cerium trichloride and cerium sulfate.

[0026] According to the present invention, the amount of the cerium salt contained in the aqueous solution only needs to meet the amount needed to prepare the nickel-based catalyst, preferably, the Ce in the aqueous solution 3+ The concentration is 0.1-0.3mol / L.

[0027] According to the present invention, cheap and easy-to-obtain zirconium salts that can be configured into aqueous solutions c...

Embodiment 1

[0060] This example is used to illustrate the method for preparing nickel-based catalyst and reduced nickel-based catalyst provided by the present invention.

[0061] (1) 0.2mol of Ce(NO 3 ) 3 ·6H 2 O and 0.2mol of ZrO(NO 3 ) 2 2H 2 O was prepared into a 1000ml mixed aqueous solution and transferred to a three-neck flask.

[0062] Put the three-neck bottle into an ultrasonic cleaner, adjust the ultrasonic power to 200W, and the ultrasonic temperature to 40°C. Under the conditions of turning on the ultrasonic wave and continuously stirring at 1000rpm, add 50ml of 3.0mol / L hydrogen peroxide dropwise to the three-necked bottle at a speed of 0.5ml / min, and at the same time add dropwise 5mol / L ammonia water to the there-necked bottle to maintain the pH of the system= 10. After the entire dropwise addition process was completed, continue to sonicate and stir for 2 hours; then stand at room temperature for aging for 10 hours, and filter with suction to obtain a solid product. ...

Embodiment 2

[0070] This example is used to illustrate the method for preparing nickel-based catalyst and reduced nickel-based catalyst provided by the present invention.

[0071] (1) 0.3mol of CeCl 3 and 0.15mol of ZrOCl 2 ·8H 2 O was prepared into a 1000ml mixed aqueous solution and transferred to a three-neck flask.

[0072] Put the three-neck bottle into an ultrasonic cleaner, adjust the ultrasonic power to 150W, and the ultrasonic temperature to 60°C. Under the conditions of turning on the ultrasonic wave and continuously stirring at 500rpm, add 30ml of 5.0mol / L hydrogen peroxide dropwise to the three-necked flask at a speed of 0.5ml / min, and at the same time, dropwise add 2mol / L ammonia water to the there-necked flask to maintain the pH of the system= 9. After the whole dropwise addition process was completed, continue to sonicate and stir for 2 hours, then stand at room temperature for aging for 10 hours, and filter with suction to obtain a solid product.

[0073] The solid pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com