Method for fast low-temperature growing of various graphical three-dimensional graphenes

A graphene and patterning technology, which is applied in the field of rapid growth of various types of patterned three-dimensional graphene at low temperature and three-dimensional graphene production, can solve the problems of complicated steps, complicated technical process, unfavorable large-scale production, etc., and achieves simple steps. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

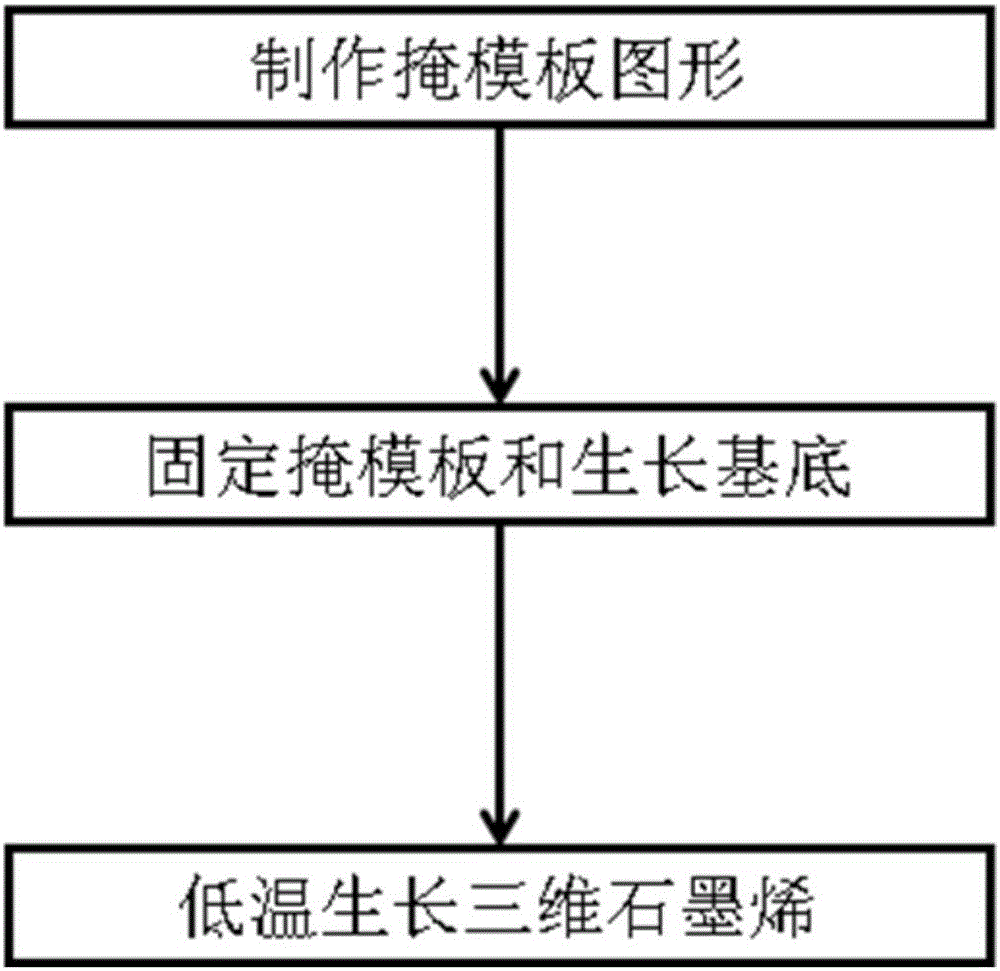

[0022] This embodiment provides a method for rapidly growing various types of patterned three-dimensional graphene at low temperature. The flowchart of the method is as attached figure 1 As shown, the specific steps are as follows:

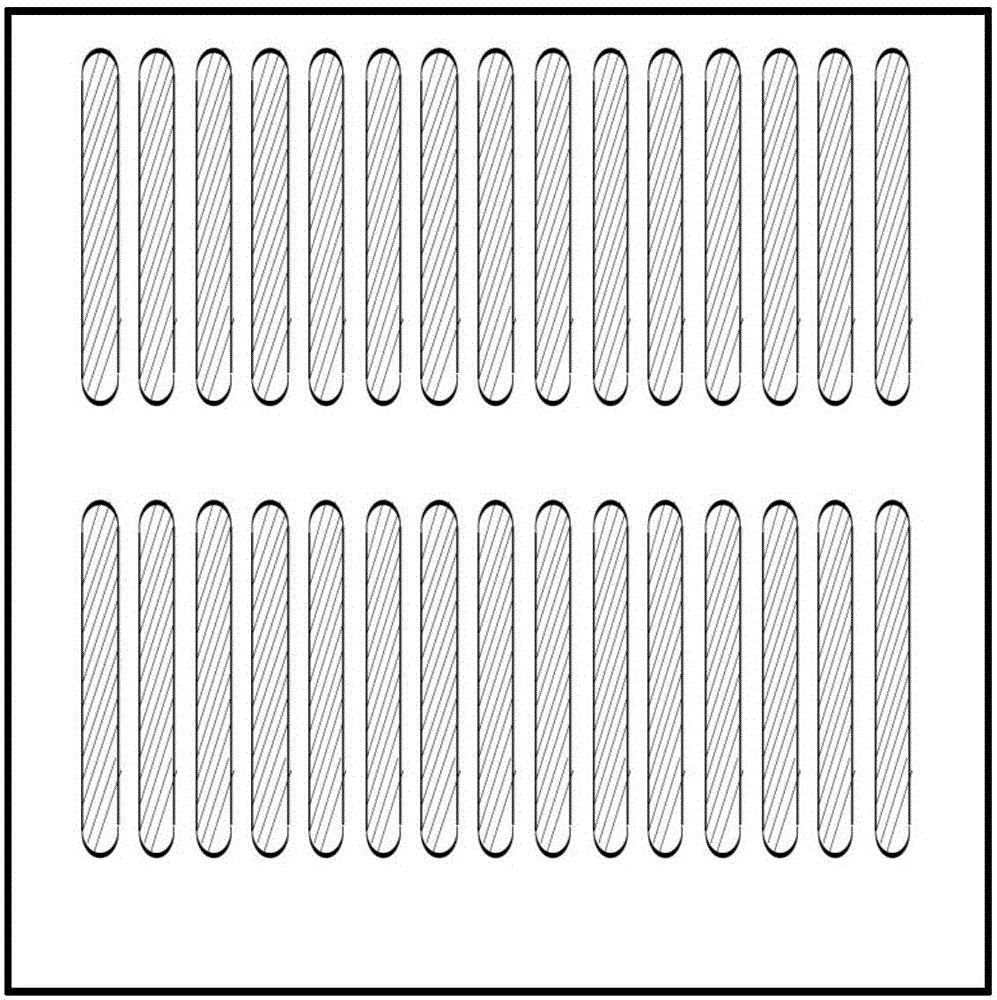

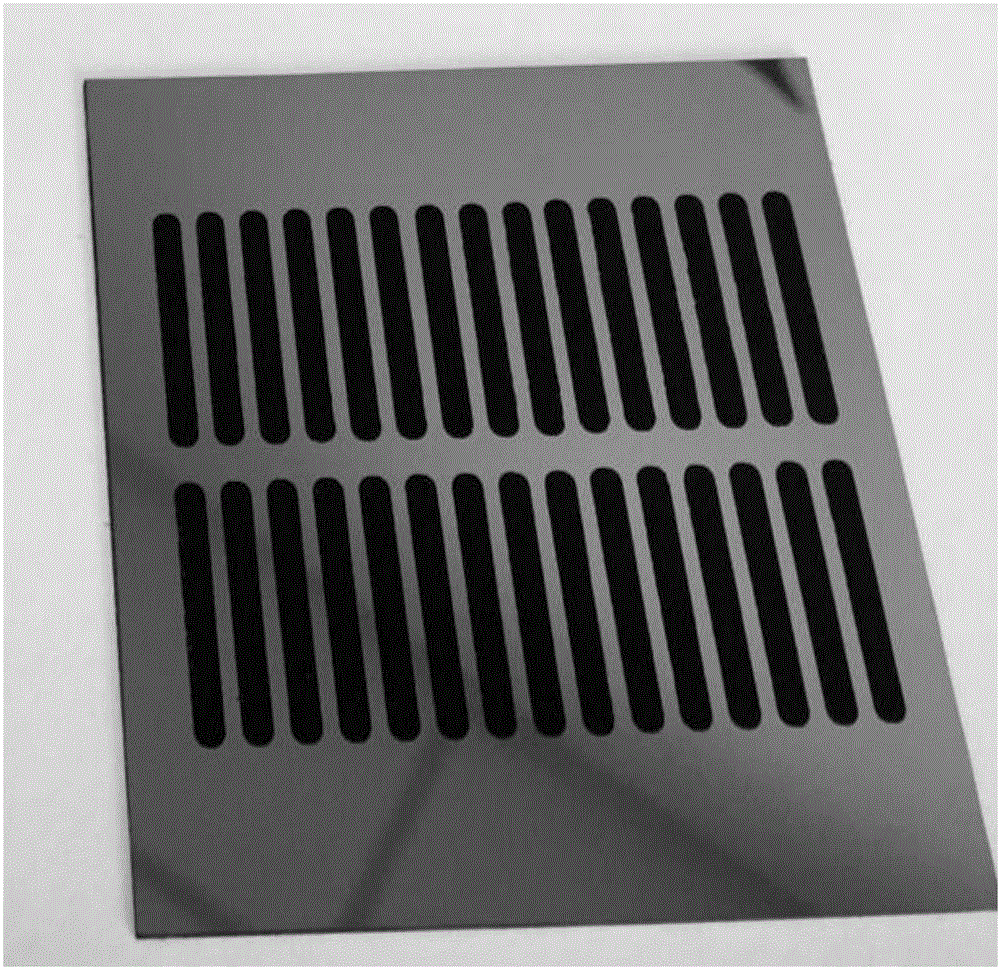

[0023] (1) Make mask pattern: choose a 6cm×6cm size copper plate as the base material of the mask, and use casting technology to make the following figure 2 The long strip mask pattern shown;

[0024] (2) Fix the mask and the growth substrate: select a silicon substrate with the same size of 6cm×6cm as the substrate for growing three-dimensional graphene, and cover the patterned mask on the growth substrate to fix the two;

[0025] (3) Low-temperature growth of three-dimensional graphene: Place the fixed mask and growth substrate in a microwave CVD vacuum chamber, vacuum with a mechanical pump to a pressure of 10 mbar, pass in hydrogen gas at a flow rate of 30 sccm, and then use argon gas carrier Enter the carbon source, the carbon source is ethanol, th...

Embodiment 2

[0027] This embodiment provides a method for rapidly growing various types of patterned three-dimensional graphene at low temperature. The flowchart of the method is as attached figure 1 As shown, the specific steps are as follows:

[0028] (1) Making the mask pattern: choose a nickel plate with a size of 5cm×5cm as the mask substrate, and use laser direct writing technology to make a petal-shaped mask pattern on the nickel plate;

[0029] (2) Fix the mask and the growth substrate: select a quartz substrate with a size of 5cm×5cm as the substrate for growing three-dimensional graphene, and cover the patterned mask on the growth substrate to fix the two;

[0030] (3) Low-temperature growth of three-dimensional graphene: place the fixed mask and growth substrate in a microwave CVD vacuum chamber, vacuum with a mechanical pump to a pressure of 50 mbar, and pass in hydrogen gas at a flow rate of 80 sccm, and then use argon gas carrier Enter the carbon source, the carbon source is methane...

Embodiment 3

[0032] This embodiment provides a method for rapidly growing various types of patterned three-dimensional graphene at low temperature. The flowchart of the method is as attached figure 1 As shown, the specific steps are as follows:

[0033] (1) Making the mask pattern: Choose a ceramic material with a size of 4cm×4cm as the base material of the mask, and use the molding technology to make a square mask pattern on the nickel plate;

[0034] (2) Fix the mask and the growth substrate: choose a copper plate with a size of 4cm×4cm as the substrate for growing three-dimensional graphene, and place the patterned mask on the growth substrate to fix the two;

[0035] (3) Low-temperature growth of three-dimensional graphene: Place the fixed mask and growth substrate in a microwave CVD vacuum chamber, vacuum with a mechanical pump to a pressure of 100 mbar, pass in hydrogen gas at a flow rate of 100 sccm, and then use argon gas carrier Enter the carbon source, the carbon source is ethylene, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com