High nitrogen compound fertilizer and preparation method thereof

A compound fertilizer, high nitrogen technology, applied in the direction of urea compound fertilizer, nitrogen fertilizer, fertilizer form, etc., can solve the problems of deterioration of soil environment quality and leaching loss in vegetable fields, and achieve the effect of avoiding irrigation loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

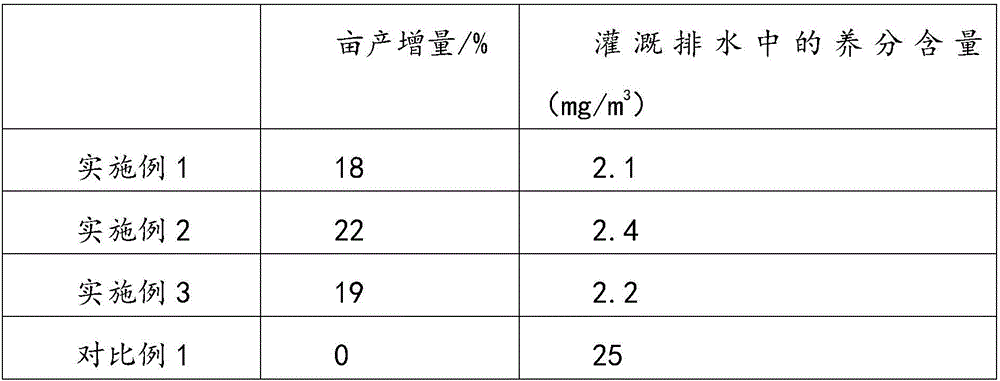

Examples

Embodiment 1

[0018] A high-nitrogen compound fertilizer, comprising: 5 parts by weight of ammonium sulfate, 2 parts of ammonium chloride, 5 parts of ammonium bicarbonate, 10 parts of urea, 2 parts of calcium cyanamide, 5 parts of potassium magnesium fertilizer, 10 parts of plant ash, and 80 parts of straw fermented products, the high-nitrogen compound fertilizer is made into granular fertilizer, wherein: the granular fertilizer is divided into an inner layer and an outer layer structure, the outer layer is straw fermented product, ammonium sulfate, ammonium chloride, Ammonium bicarbonate, urea, calcium cyanamide, potassium magnesium fertilizer and plant ash are all located in the inner layer.

[0019] A preparation method of high-nitrogen compound fertilizer, comprising the steps of:

[0020] Equipped with raw materials, the high-nitrogen compound fertilizer includes in parts by weight: 5 parts of ammonium sulfate, 2 parts of ammonium chloride, 5 parts of ammonium bicarbonate, 10 parts of ...

Embodiment 2

[0024] A high-nitrogen compound fertilizer, comprising: 8 parts by weight of ammonium sulfate, 3 parts of ammonium chloride, 4 parts of ammonium bicarbonate, 8 parts of urea, 3 parts of calcium cyanamide, 6 parts of potassium magnesium fertilizer, 9 parts of plant ash, and 75 parts of straw fermented product, the high-nitrogen compound fertilizer is made into granular fertilizer, wherein: the granular fertilizer is divided into inner layer and outer layer structure, the outer layer is straw fermented product, ammonium sulfate, ammonium chloride, Ammonium bicarbonate, urea, calcium cyanamide, potassium magnesium fertilizer and plant ash are all located in the inner layer.

[0025] A preparation method of high-nitrogen compound fertilizer, comprising the steps of:

[0026] Equipped with raw materials, the high-nitrogen compound fertilizer includes in parts by weight: 8 parts of ammonium sulfate, 3 parts of ammonium chloride, 4 parts of ammonium bicarbonate, 8 parts of urea, 3 pa...

Embodiment 3

[0030] A high-nitrogen compound fertilizer, comprising: 10 parts by weight of ammonium sulfate, 4 parts of ammonium chloride, 3 parts of ammonium bicarbonate, 5 parts of urea, 4 parts of calcium cyanamide, 7 parts of potassium and magnesium fertilizers, 8 parts of plant ash, and 70 parts of straw fermented product, the high-nitrogen compound fertilizer is made into granular fertilizer, wherein: the granular fertilizer is divided into an inner layer and an outer layer structure, the outer layer is straw fermented product, ammonium sulfate, ammonium chloride, Ammonium bicarbonate, urea, calcium cyanamide, potassium magnesium fertilizer and plant ash are all located in the inner layer.

[0031] A preparation method of high-nitrogen compound fertilizer, comprising the steps of:

[0032] Equipped with raw materials, the high-nitrogen compound fertilizer includes in parts by weight: 10 parts of ammonium sulfate, 4 parts of ammonium chloride, 3 parts of ammonium bicarbonate, 5 parts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com