Process for the production of aromatics

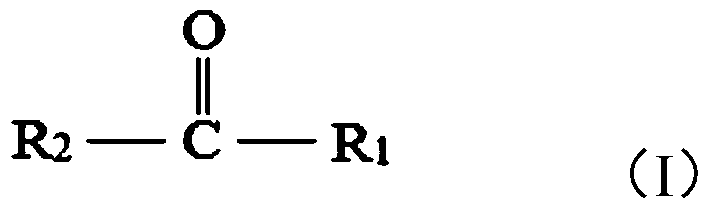

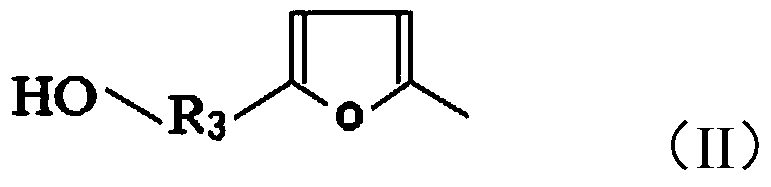

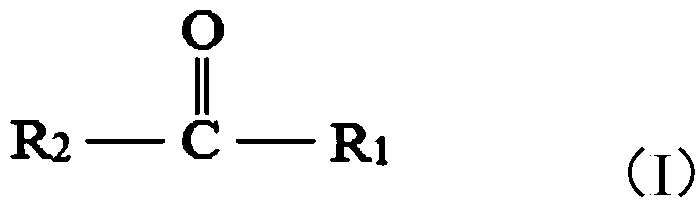

A production method and technology for aromatic hydrocarbons, which are used in the production of hydrocarbons from oxygen-containing organic compounds, organic chemistry, etc., to achieve good technical effects, good selectivity, and the effect of solving long reaction steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Weigh 5 grams of WO which has been dried at 120℃ for 12 hours to remove water 3 / ZrO 2 The proportion of the catalyst and the metal oxide is 3 / 97, which is charged into the fixed bed reactor. Furfural Weight airspeed 0.5 hour -1 , Hydrogen pressure 1.0MPa, flow rate 20ml min -1 , The temperature is 400℃. After the reaction, mass spectrometry is used for qualitative analysis of the reaction results, and chromatography is used for quantitative analysis of the reaction results. The conversion rate of the reaction substrate was 75%, and the selectivity of BTX was 89%.

Embodiment 2

[0030] Weigh 60 grams of corn stalks, place them in an autoclave and add 700 grams of water, then add a 5mol / L sulfuric acid solution with 7% water mass, heat up to 180°C and react for 45 minutes, then cool, and then cool the cooled reaction liquid Filter to obtain a filter cake and a filtrate. The filtrate is a cellulose hydrolysate. After the reaction, mass spectrometry is used to identify the main product of the reaction result as levulinic acid, and its production amount is 18 grams.

[0031] Weigh 5 grams of WO which has been dried at 120℃ for 12 hours to remove water 3 / ZrO 2 The proportion of the catalyst and the metal oxide is 5 / 95, which is charged into the fixed bed reactor. Levulinic acid Weight airspeed 1.0 hour -1 , Hydrogen pressure 1.0MPa, flow rate 50ml min -1 , The temperature is 450°C. After the reaction, mass spectrometry is used for qualitative analysis of the reaction results, and chromatography is used for quantitative analysis of the reaction results. The...

Embodiment 3

[0033] Weigh 60 grams of rice straw, place it in an autoclave and add 700 grams of water, and then add a 5mol / L sulfuric acid solution of 7% water mass, heat up to 210°C and react for 30 minutes, then cool, and then cool the cooled reaction solution. Filter to obtain filter cake and filtrate. The filtrate is a cellulose hydrolysate. After the reaction, mass spectrometry is used to identify the main product of the reaction result as levulinic acid, and its production amount is 22.8 grams.

[0034] Weigh 5 grams of WO which has been dried at 120℃ for 12 hours to remove water 3 / ZrO 2 The proportion of the catalyst and the metal oxide is 20 / 80, which is charged into the fixed bed reactor. Levulinic acid Weight airspeed 2.5 hours -1 , Hydrogen pressure 2.0MPa, flow rate 20ml min -1 , The temperature is 380℃. After the reaction, mass spectrometry is used for qualitative analysis of the reaction results, and chromatography is used for quantitative analysis of the reaction results. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com