A kind of method for extracting avelamycin

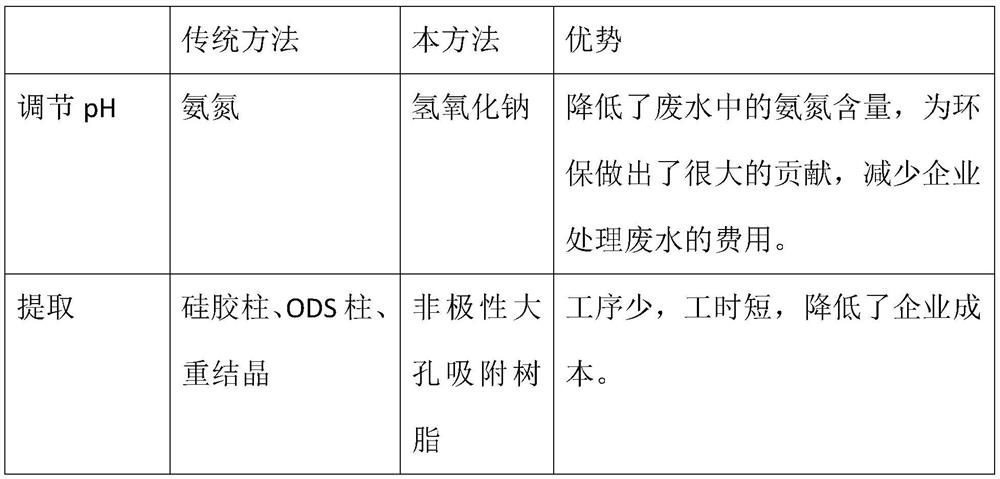

A technology of avilamycin and alkaline solvent, applied in the field of extracting avilamycin, can solve the problems of long process, low product yield and high cost, and achieve the effects of less process, lower ammonia nitrogen content and short working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] With 50L of avelamycin fermented liquid, titer 4656U / mL, product weight 233g. Use sodium hydroxide to adjust the pH to 8.2, followed by solid-liquid separation; the obtained solid is dried to obtain a dry powder and then pulverized, an organic solvent is added to the pulverized solid, and stirred for 1.5 hours, during which the temperature is controlled at 42 ° C, filtered, and the obtained filtrate Standby; the filtrate is decolorized with 2% activated carbon, and the obtained solution is transferred to a non-polar macroporous adsorption resin for adsorption, and then the resin column is analyzed with 60% ethanol to collect the analysis solution; the analysis solution is evaporated, concentrated and dried to obtain Avila Mycin finished product 128g, content 82.1%, yield 54.9%.

Embodiment 2

[0029] With neomycin sulfate fermentation liquid 60L, potency 4832U / ml, product weight 290g. Use sodium hydroxide to adjust the pH to 8.5, followed by solid-liquid separation; the obtained solid is dried to obtain a dry powder and then pulverized, an organic solvent is added to the pulverized solid, stirred for 2.0 hours, during which the temperature is controlled at 45 ° C, filtered, and the obtained filtrate Standby; the filtrate is decolorized with 3% activated carbon, and the obtained solution is transferred to a non-polar macroporous adsorption resin for adsorption, and then the resin column is analyzed with 65% ethanol to collect the analysis solution; the analysis solution is evaporated, concentrated and dried to obtain Avila Mymycin finished product 165g, content 81.5%, yield 56.9%.

Embodiment 3

[0031] With 70L of neomycin sulfate fermented liquid, titer 4938U / mL, product weight 346g. Use sodium hydroxide to adjust the pH to 8.7, followed by solid-liquid separation; the obtained solid is dried to obtain a dry powder and then pulverized, an organic solvent is added to the pulverized solid, stirred for 2.5 hours, during which the temperature is controlled at 48 ° C, filtered, and the obtained filtrate Standby; the filtrate is decolorized with 5% activated carbon, and the obtained solution is transferred to a non-polar macroporous adsorption resin for adsorption, and then the resin column is analyzed with 75% ethanol to collect the analysis solution; the analysis solution is evaporated, concentrated and dried to obtain Avila Mycin finished product 194g, content 83.6%, yield 56.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com