Waterborne pigment dispersant

A technology of water-based pigments and dispersants, applied in the direction of pigment slurry, coating, etc., can solve the problems of insufficient adhesion of dispersants to substrates, poor pigment dispersion ability, poor storage stability, etc., to avoid tinting strength and stability Effects of drop, adhesion enhancement, strong adsorption and dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

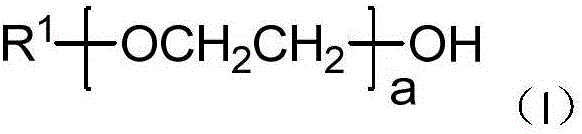

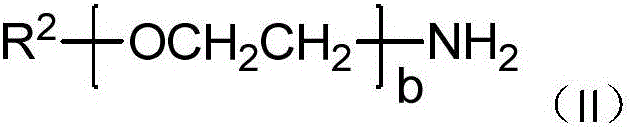

Method used

Image

Examples

Embodiment 1

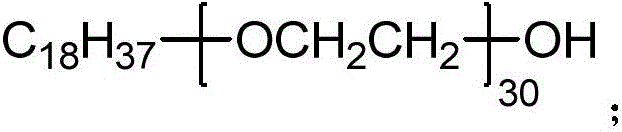

[0047] Add 130g of 1,4-dioxane and 29.4g of maleic anhydride to a 1000mL four-neck round bottom flask equipped with a stirrer and reflux condensing device at one time, place the flask in a constant temperature oil bath, heat and stir to 100°C . Add 41.66g styrene, 0.26g divinylbenzene, 21.6g acrylic acid, 1.9g azobisisobutyronitrile, 2.5g dodecanethiol, 18g 1,4-dioxane into a 200mL constant pressure titration funnel The mixture is added dropwise in the reactor, and the dropwise addition time is 2 hours, and the reaction is continued for 2 hours after the dropwise addition ends. Add 120 g of graft modifier A and 4 g of triethylamine into the four-neck flask, maintain the temperature at 80° C., and the reaction time is 4 hours. After the reaction, the solvent 1,4-dioxane was distilled off and cooled to room temperature to obtain a graft-modified cross-linked styrene-divinylbenzene-maleic anhydride-acrylic acid copolymer. After testing, the weight average molecular weight of th...

Embodiment 2

[0049] Add 350g of 1,4-dioxane and 24.52g of maleic anhydride to a 1000mL four-neck round bottom flask equipped with a stirrer and reflux condensing device at one time, place the flask in a constant temperature oil bath, heat and stir to 90°C . Add a mixture of 62.49g styrene, 0.65g divinylbenzene, 10.8g acrylic acid, 6g benzoyl peroxide, 2.93g dodecanethiol, and 60g tetrahydrofuran into a 200mL constant pressure titration funnel, and add it dropwise to the reactor , the dropwise addition time was 4 hours, and the reaction was continued for 3 hours after the dropwise addition ended. Add 59g of graft modifier B and 4g of 4-dimethylaminopyridine into the four-neck flask, the temperature rises to 100°C, and the reaction time is 2 hours. After the reaction, the solvent tetrahydrofuran was distilled off and cooled to room temperature to obtain a graft-modified cross-linked styrene-divinylbenzene-maleic anhydride-acrylic acid copolymer. After testing, the weight average molecular ...

Embodiment 3

[0051] Add 260g of cyclohexane and 49.03g of maleic anhydride in a 1000mL four-necked round bottom flask equipped with a stirrer and reflux condensing device at one time, place the flask in a constant temperature oil bath, heat and stir to 70°C. Add 41.66g styrene, 0.92g divinylbenzene, 7.21g acrylic acid, 9.7g tert-butyl peroxybenzoate, 2.1g α-methylstyrene linear dimer, 40g cyclohexyl to a 200mL constant pressure titration funnel The mixture of alkanes, the dropwise addition time was 3 hours, and the reaction was continued for 1 hour after the dropwise addition was completed. Add 120 g of graft modifier C and 3 g of aluminum trichloride into the four-neck flask, maintain the temperature at 70° C., and the reaction time is 6 hours. After the reaction, the solvent was distilled off and cooled to room temperature to obtain a graft-modified cross-linked styrene-divinylbenzene-maleic anhydride-acrylic acid copolymer. After testing, the weight average molecular weight of the obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com