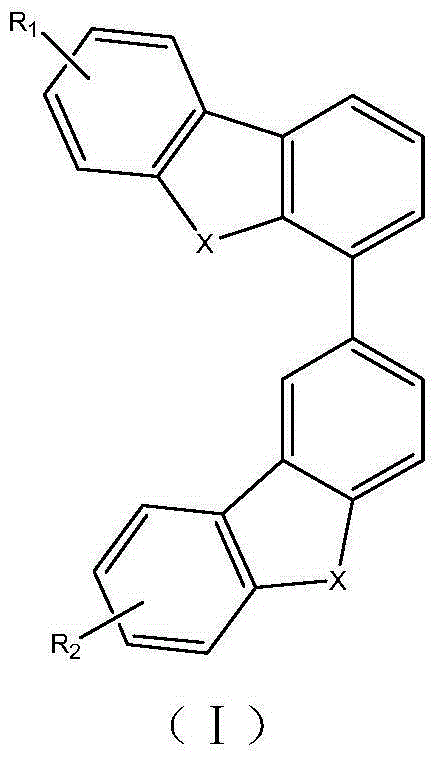

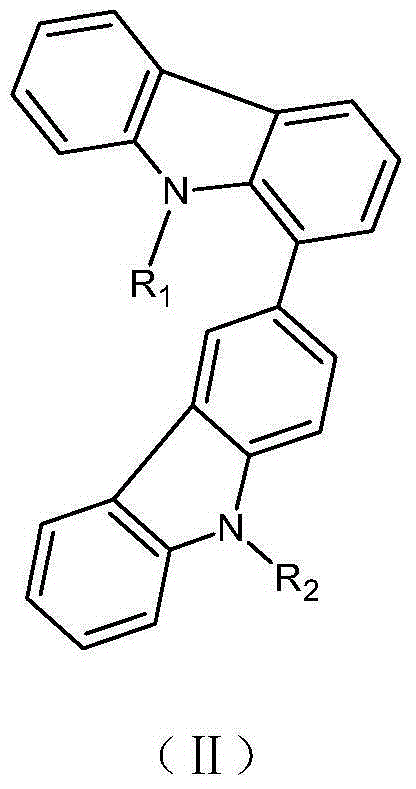

Organic electroluminescent compound and application thereof

A compound and electroluminescence technology, applied in the field of compounds, can solve the problems of low luminous efficiency and insufficient carrier transport efficiency, and achieve the effects of improving luminous efficiency, improving carrier transport efficiency, and improving industrialization prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] In addition, the present invention provides a method for preparing the above-mentioned OLED device, comprising the following steps:

[0052] 1) Ultrasonic cleaning of the transparent anode electrode ITO substrate in isopropanol for 5-10 minutes, and exposure to ultraviolet light for 20-30 minutes, followed by plasma treatment for 5-10 minutes;

[0053] 2) Put the processed ITO substrate into the evaporation equipment, and first evaporate the hole transport layer material as the hole transport layer;

[0054] 3) Then evaporate the light-emitting layer, mix and evaporate the material of the light-emitting layer, and 5--10% Ir(ppy)3;

[0055] 4) Then use the electron transport layer material to vapor-deposit an electron transport layer, then vapor-deposit 0.5-2nm LiF, and then vapor-deposit 100-200nm metal Al;

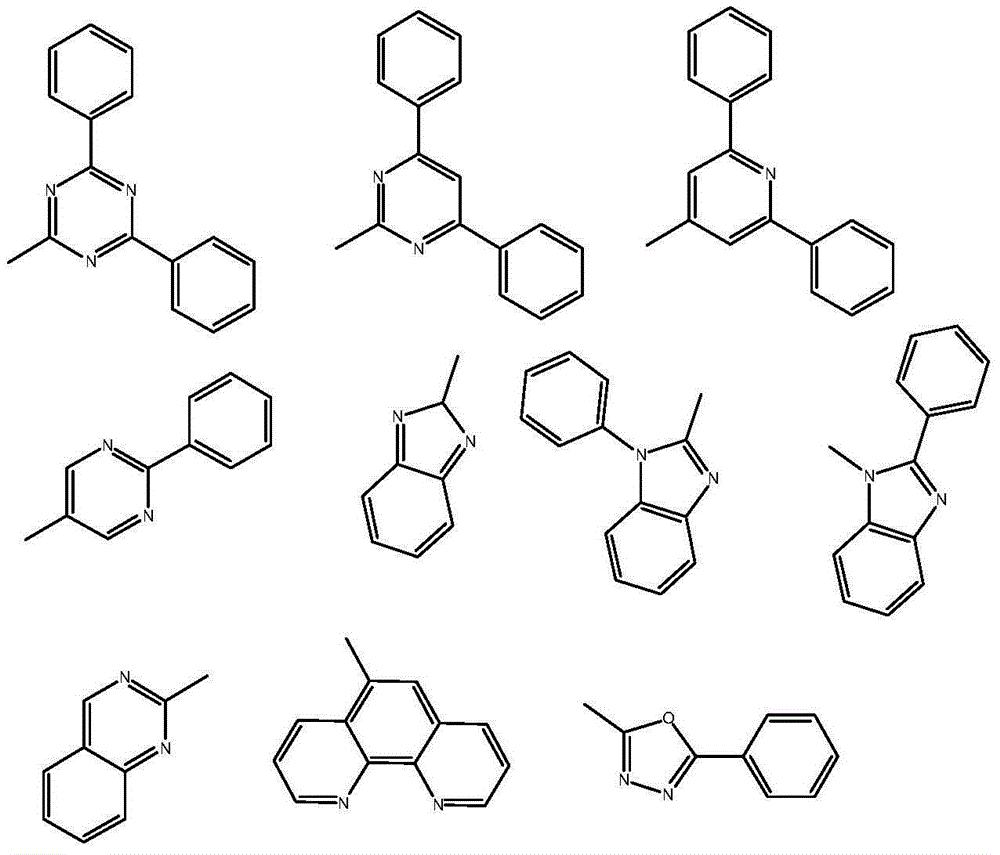

[0056] Wherein, one of the hole transport layer material, light emitting layer material, and electron transport layer material is a compound represented by genera...

Embodiment 1

[0063] The preparation method of compound 1

[0064]

[0065] Dissolve 100mmol of compound 1-a and 220mmol of 4-bromobiphenyl in 1000ml of toluene, and add 300mmol of sodium tert-butoxide and 2mmol of catalyst Pd[P(t-Bu) 3 ] 2 , and refluxed for 6 hours under the protection of nitrogen. Then, add distilled water to the reaction solution to terminate the reaction, extract with dichloromethane, wash with brine, separate the organic layer, remove the organic solvent by rotary evaporation, pass the crude product through the column, recrystallize and purify with dichloromethane and ethanol, and dry in vacuo to obtain 82 mmol product compound 1.

[0066] Molecular weight characterization MS 636.26;

[0067] 1 H-NMR: 8.01(1H), 8.05(1H), 7.82(1H), 7.85(1H), 7.61(1H), 7.57(1H), 7.53(2H), 7.43(2H), 7.32(2H), 7.28( 2H), 7.23(4H), 7.61(4H), 7.64(4H), 7.36(4H), 7.28(2H).

Embodiment 2

[0069] The preparation method of compound 2

[0070]

[0071] Dissolve 100mmol of compound 2-a and 120mmol of 4-bromobiphenyl and 120mmol of 3-bromobiphenyl in 1000ml of toluene, and add 300mmol of sodium tert-butoxide and 2mmol of catalyst Pd[P(t-Bu) 3 ] 2 , and refluxed for 6 hours under the protection of nitrogen. Then, add distilled water to the reaction solution to terminate the reaction, extract with dichloromethane, wash with brine, separate the organic layer, remove the organic solvent by rotary evaporation, pass the crude product through the column, recrystallize and purify with dichloromethane and ethanol, and dry in vacuo to obtain 70mmol product compound 2.

[0072] Molecular weight characterization MS 636.26;

[0073] 1 H-NMR: 8.03(1H), 8.02(1H), 7.81(1H), 7.82(1H), 7.67(1H), 7.59(1H), 7.53(2H), 7.43(2H), 7.32(2H), 7.28 (2H), 7.23--7.61(8H), 7.34--7.74(8H), 7.28(1H), 7.31(1H).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com