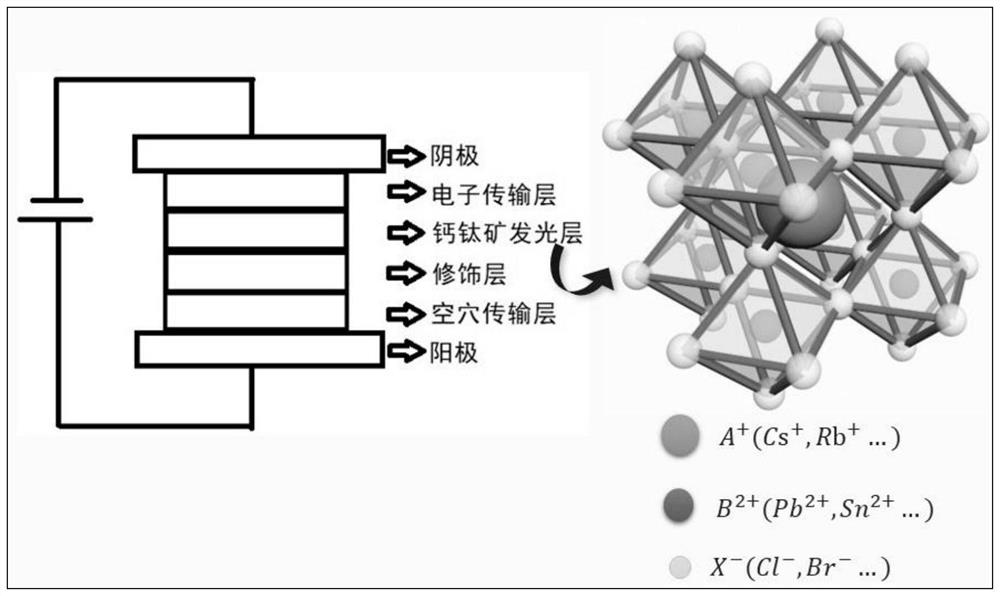

Perovskite light emitting diode containing modification layer and evaporation preparation method thereof

A technology of light-emitting diodes and perovskites, which is applied in the field of preparation of perovskite light-emitting diodes, can solve the problems of many film defects, poor appearance quality of perovskite light-emitting layers, and poor performance of light-emitting diodes, so as to increase device performance, Improving carrier transport efficiency and improving the effect of interface barrier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

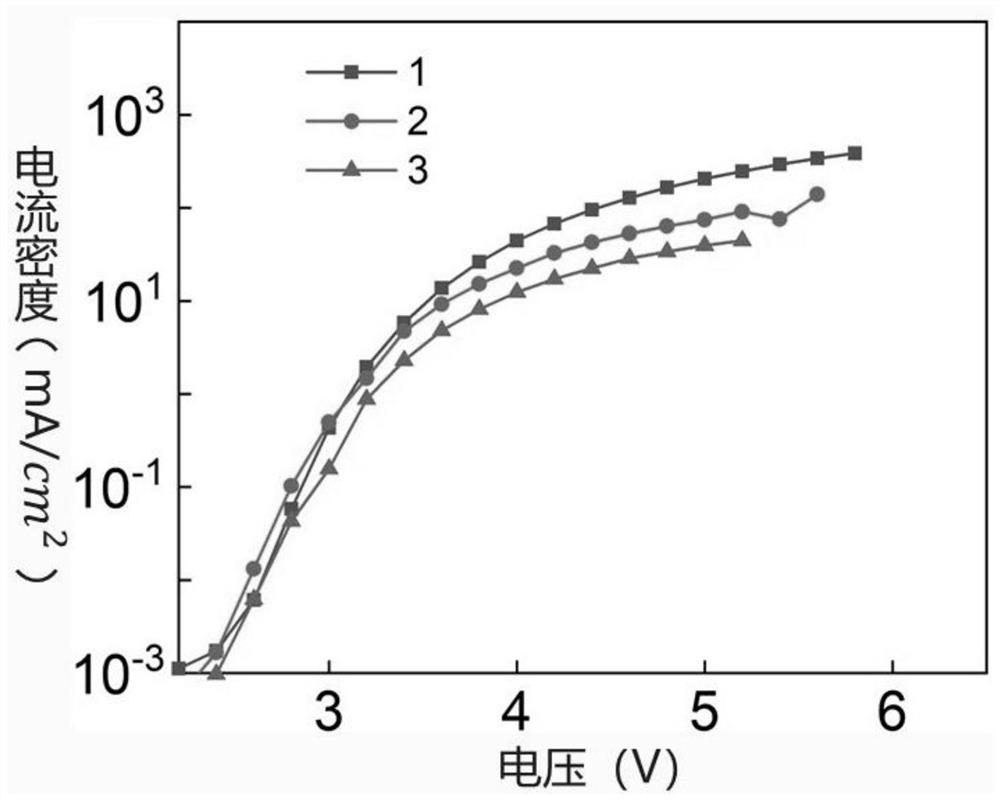

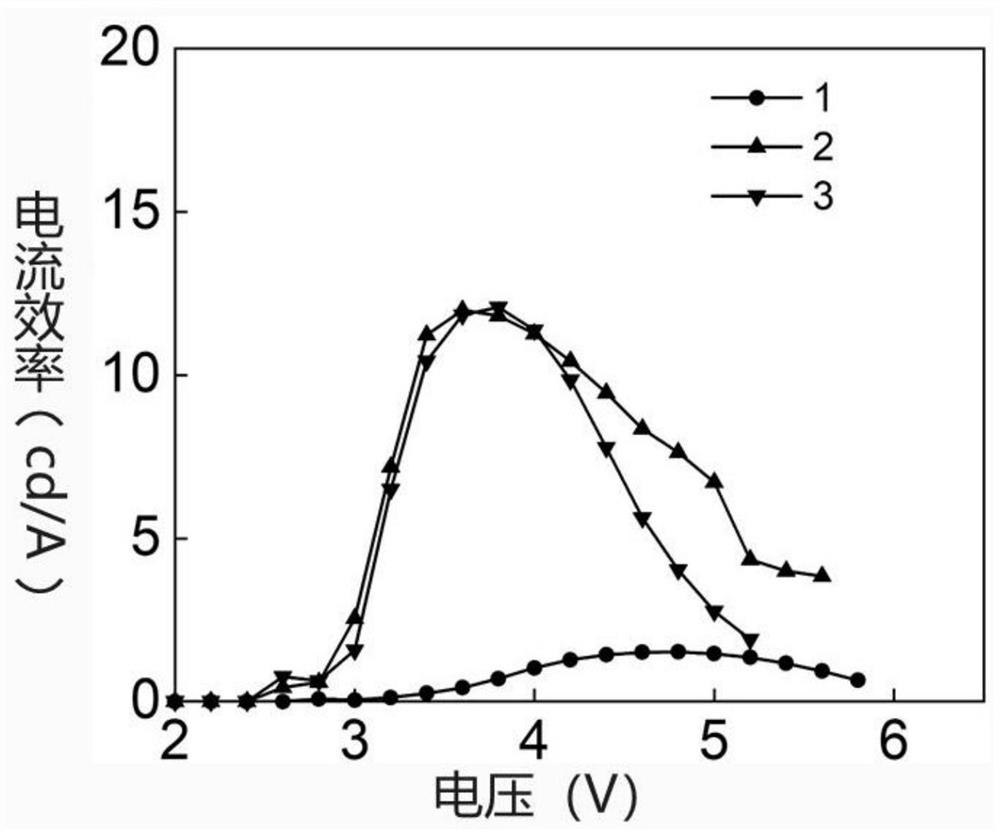

Examples

Embodiment 1

[0071] The preparation method of the second perovskite light-emitting diode comprises the following steps:

[0072] ①The preparation process of 4-aminobutyric acid is to stir 100mg of drug powder and 1ml of deionized water evenly. Take 0.1 ml of 4-aminobutyric acid solution and 1 ml of PEDOT:PSS (the volume ratio of the two is 1:10), mix and stir, and the hole transport layer includes poly(3,4-ethylenedioxythiophene)-poly( styrene sulfonate) (PEDOT:PSS). The amino acid solution can be doped with water-soluble PEDOT:PSS solution and then spin-coated. Mix 100 microliters of 4-aminobutyric acid with a concentration of 100 mg / ml and 1000 microliters of PEDOT:PSS to obtain a mixed solution;

[0073] ②The ultrasonic-treated glass substrate (20*20mm) with a transparent anode layer (185nm thick, single ITO is 4*20mm), i.e. indium tin oxide (ITO), was placed on the spin coater after UV ozone treatment, and 0.05ml of The mixed solution obtained in the previous step was evenly coated ...

Embodiment 2

[0079] The preparation method of the second perovskite light-emitting diode comprises the following steps:

[0080] ①The preparation process of 4-aminobutyric acid is to mix 50mg of drug powder and 1ml of deionized water evenly. 0.1 ml of 4-aminobutyric acid solution and 1 ml of PEDOT:PSS were mixed and stirred, and the hole transport layer included poly(3,4-ethylenedioxythiophene)-poly(styrene sulfonate) (PEDOT:PSS). The amino acid solution can be doped with water-soluble PEDOT:PSS solution and then spin-coated. Mix 100 microliters of 50 mg / ml 4-aminobutyric acid with 1000 microliters of PEDOT:PSS to obtain a mixed solution

[0081] ② Put the ultrasonically treated glass substrate (20*20mm) with a transparent anode layer (185nm thick, a single ITO is 4*20mm), that is, indium tin oxide (ITO), on the spin coater after UV ozone treatment, take 0.05ml The mixed solution obtained in the previous step was evenly coated on the entire film, and was spin-coated at a speed of 6000 rp...

Embodiment 3

[0087] The preparation method of the first perovskite light-emitting diode comprises the following steps:

[0088] ①The preparation process of glycine solution is to mix 50mg of drug powder and 1ml of deionized water evenly.

[0089] ②The ultrasonic-treated glass substrate (20*20mm) with a transparent anode layer (185nm thick, a single ITO is 4*20mm), that is, indium tin oxide (ITO), was placed on the spin coater after UV ozone treatment, and passed through 0.22 micron The filter uniformly coats the entire film with PEDOT:PSS, spin-coating at 6000 rpm for 30 s through a spin coater, and annealing at 140°C for 10 minutes to form a hole transport layer on the anode.

[0090] ③Place the annealed substrate with the hole transport layer on the spin coater, take 0.1ml of 50mg / ml glycine with a pipette and spin-coat on the substrate, and spin the spin coater at a speed of 8000 rpm for 30s , and the interface modification layer was formed after high temperature annealing at 100°C for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com