Phosphine-containing perylene diimide interface material, synthesis method thereof and solar cell

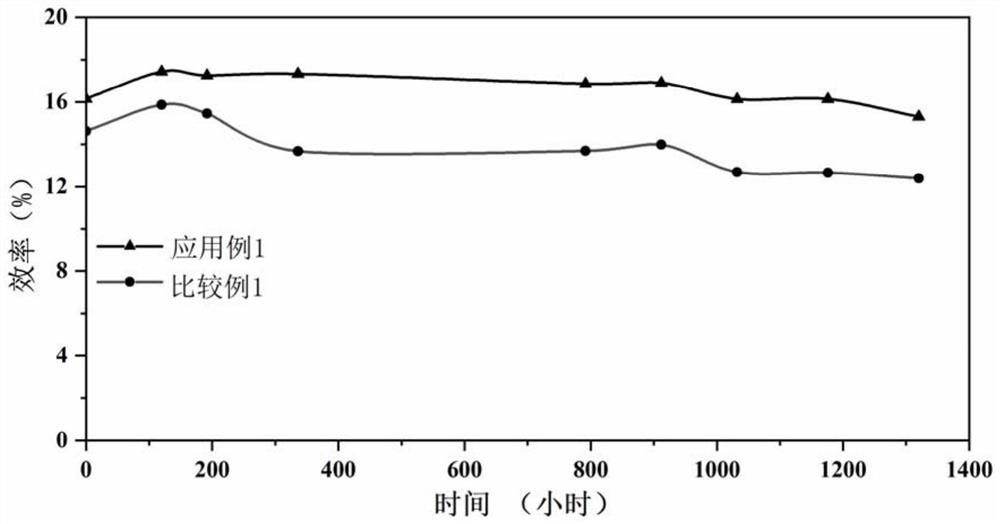

A perylene diimide and interface material technology, which is applied in the field of solar cells, can solve the problems of low photoelectric conversion efficiency and stability performance of perovskite solar cells, unfavorable large-scale commercial applications, etc., to reduce interface defects, Improving the effect of interface defects and improving interface barriers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

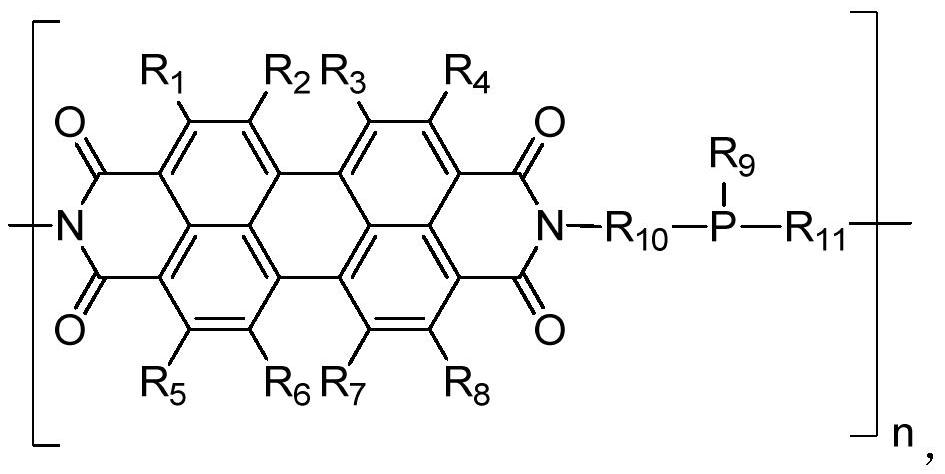

[0030] A kind of interface material, its preparation method comprises the following steps:

[0031] S1. Polymerize 3,4,9,10-perylenetetracarboxylic dianhydride and bis(3-aminopropyl)phenylphosphine precursor at high temperature. Specifically, the two precursors were placed in the same sealed tube at a mass ratio of 1:1, and imidazole was used to provide a basic environment and act as a reaction solvent at the same time, and the polymerization reaction was carried out at 180 °C.

[0032] S2, using 10wt% K 2 CO 3 The solution is reacted with alkaline solution to remove insoluble monomers not completely reacted in step S1, and then filtered, and the retentate is washed with distilled water and ethanol in sequence, and then dried to obtain an interface material.

Embodiment 2

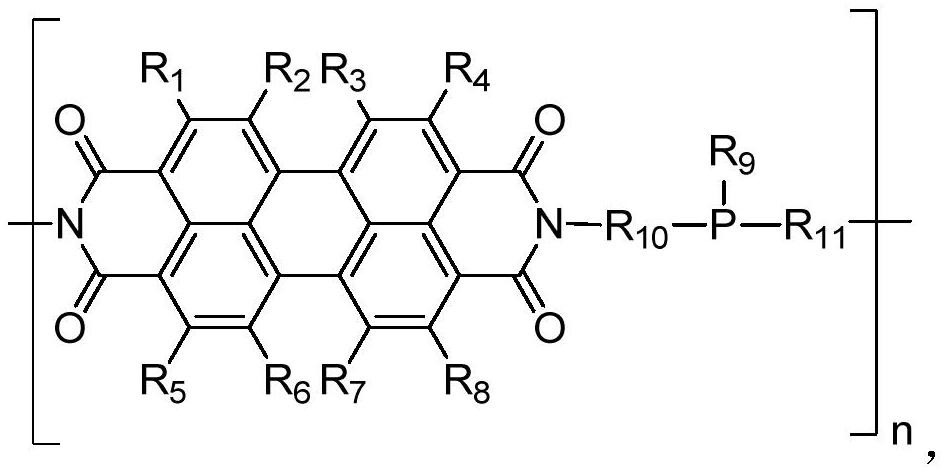

[0034] A kind of interface material, its preparation method comprises the following steps:

[0035] S1. According to the mass ratio of 1:1, take the reaction monomer bis(3-aminopropyl)phenylphosphine and 1,6,7,12-tetrachloro-3,4,9,10-tetracarboxylic dianhydride to Molten imidazole was used as the reaction solvent, and refluxed at 180°C for 8 hours under the protection of nitrogen, so that the reaction monomers were polymerized;

[0036] S2. Cool the reaction system obtained in step S1 to room temperature, and then mix with 10wt% K 2 CO 3 The solution was reacted for 3 hours to remove the incompletely reacted monomer in step S1 through alkali reaction, and then filtered, and the retentate was washed with deionized water and ethanol in sequence, and then dried to obtain an interface material.

Embodiment 3

[0038] A kind of interface material, its preparation method comprises the following steps:

[0039] S1. According to the mass ratio of 1:1, take the reaction monomer bis(3-aminopropyl)phenylphosphine and 1,6,7,12-tetrachloro-3,4,9,10-tetracarboxylic dianhydride to N-methylpyrrolidone is used as a solvent, reflux reaction at 180°C for 8 hours under nitrogen protection, and reflux reaction under nitrogen protection, so that the reaction monomers undergo polymerization reaction;

[0040] S2. Cool the reaction system obtained in step S1 to room temperature, and then mix with 10wt% K 2 CO 3 The solution was reacted for 3 hours to remove the incompletely reacted monomer in step S1 by alkaline reaction, and then filtered, and the retentate was washed with distilled water and ethanol in sequence, and then dried to obtain an interface material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com