A kind of carbon-pillared mxene composite material and its application

A technology of composite materials and carbon pillars, applied in hybrid capacitor electrodes, structural parts, electrical components, etc., can solve the problems of low application capacity, limit the application prospects of MXene, and the incomplete utilization of interlayer energy storage space, etc., to achieve multi-capacity , meet the requirements of use, and the effect of stable cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

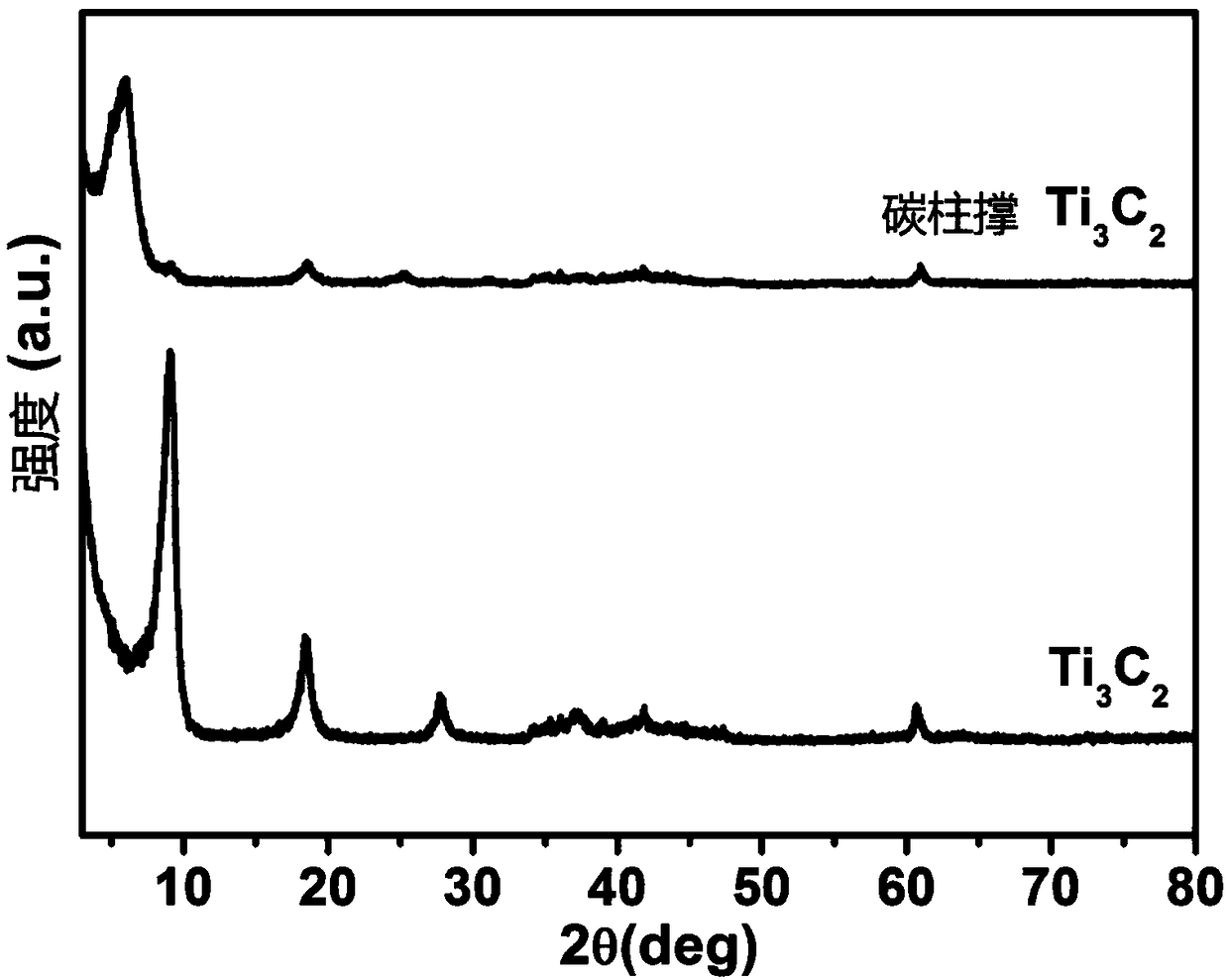

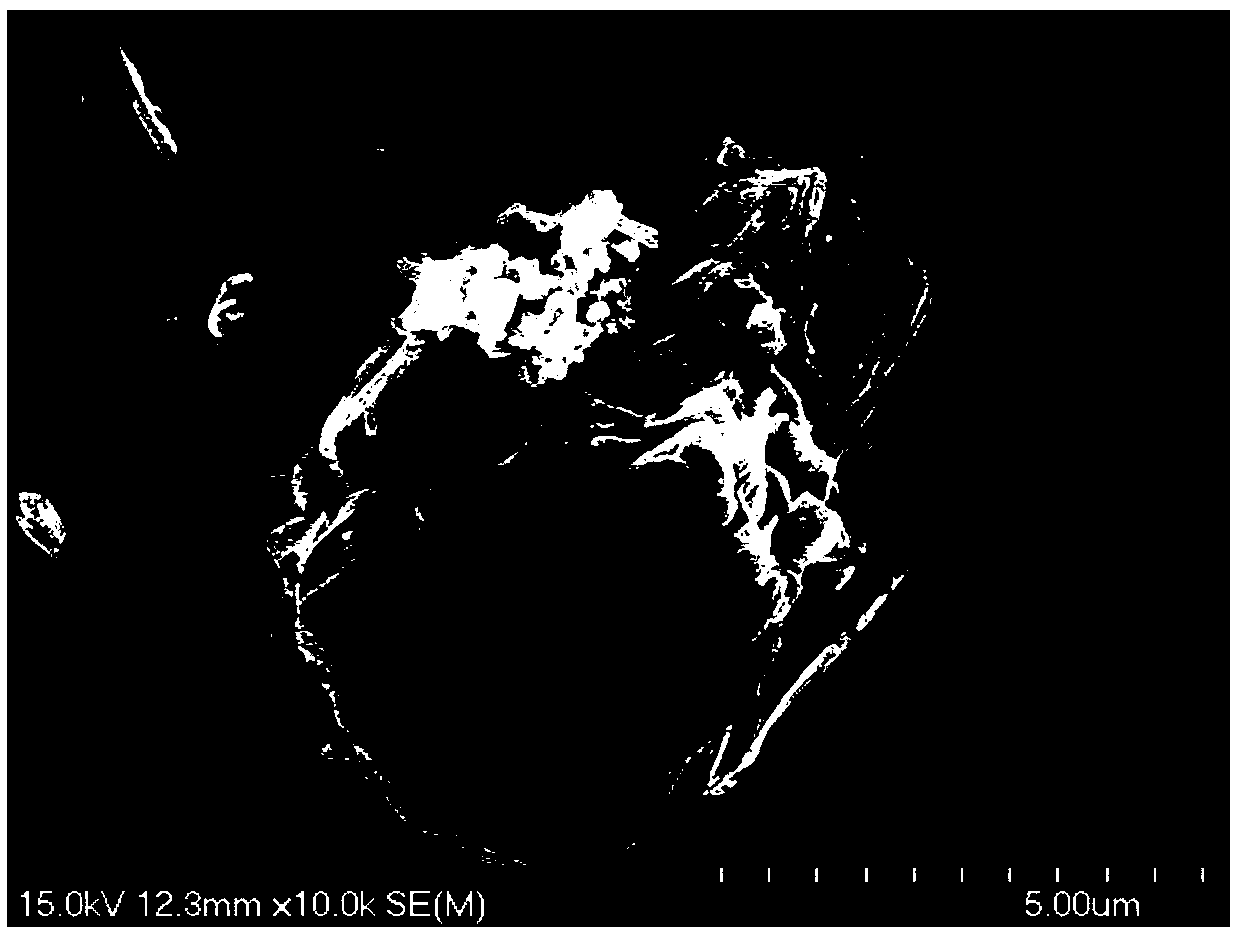

[0021] Take 3g Ti 3 AlC 2 Put the powder (MAX) into a beaker, add 10ml of HF solution with a mass fraction of 40%, stir, and etch at room temperature for 16h. Then the etched Ti 3 C 2 The MXene powder was centrifuged, washed with deionization to PH = 6-7, and baked in a blast oven at 80°C for 12 hours. The dried 0.1g Ti 3 C 2 MXene powder, stirred in 40mL aqueous solution containing 0.05g / mL gelatin (Aladdin reagent, chemically pure) at 50°C for 5h, centrifuged, cleaned with deionization, dried, and then heated at a rate of 10°C / min in a nitrogen atmosphere Insulated at 500°C for 2h to obtain carbon pillared Ti 3 C 2 MXene material.

[0022] With the carbon pillar Ti made in embodiment 1 3 C 2 MXene material powders were prepared into electrodes as follows.

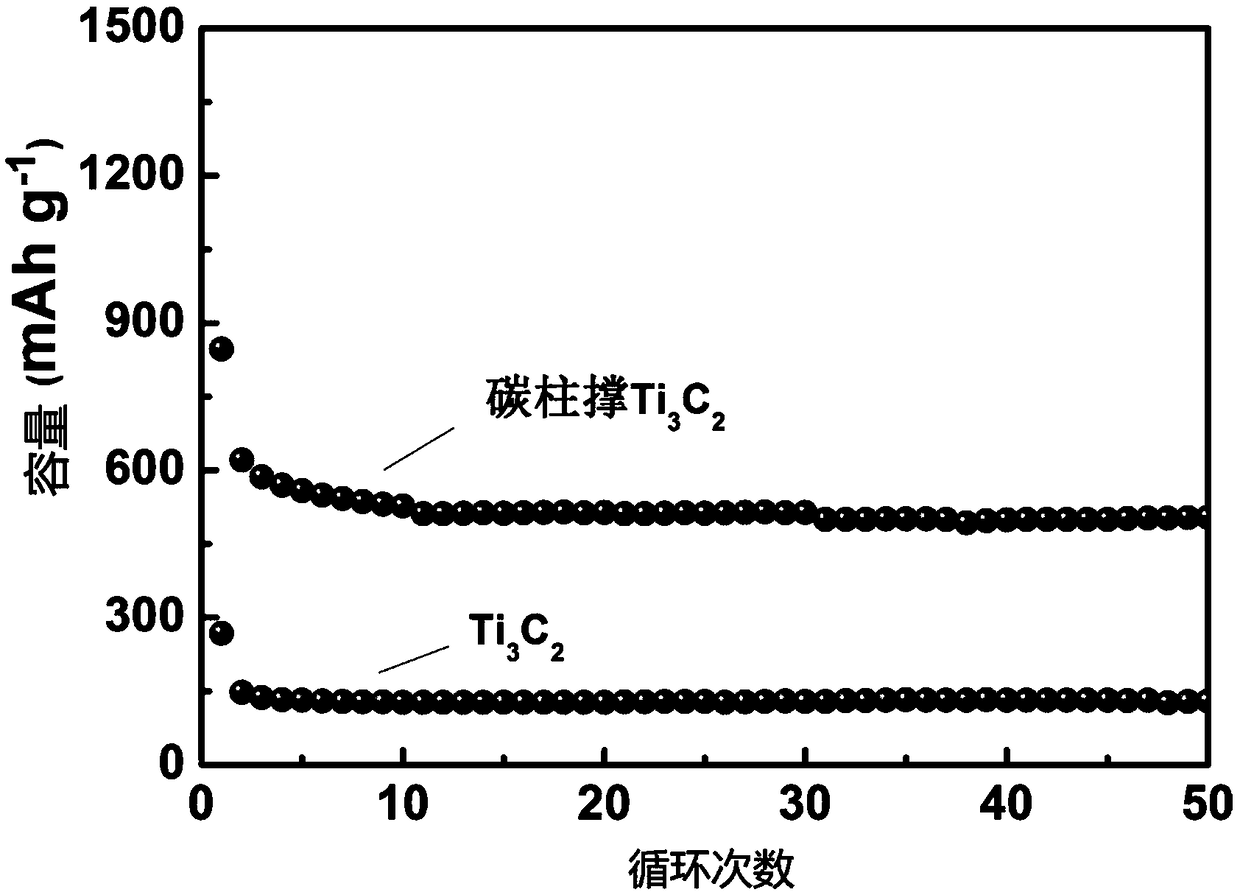

[0023] Weigh the carbon-pillared Ti with a mass ratio of 80:10:10 3 C 2 MXene material: super-P: PVDF, ground evenly to make electrode, metal lithium sheet as counter electrode, electrolyte is 1mol / L LiPF 6 ...

Embodiment 2

[0026] Take 2.5g Ti 2 Put AlC powder into a beaker, add 30ml of HF solution with a mass fraction of 40%, stir, and etch at room temperature for 8h. Then the etching powder is centrifuged out of Ti 2C MXene powder, washed with deionization to PH = 6-7, baked in a blast oven at 80°C for 12h. 0.2g dried Ti 2 C MXene powder, stirred in 50mL aqueous solution containing 0.5g / mL polydiallyldimethylammonium chloride (Aladdin reagent, Mw 100000-200000, 20wt.% aqueous solution, CP) at 60°C for 4h, centrifuged, and Deionized cleaning, drying, and holding at 500°C for 2 hours at a heating rate of 5°C / min in an argon atmosphere to obtain carbon pillared Ti 2 CMXene material. Using the prepared carbon pillars to support Ti 2 The C MXene material is made into an electrode according to the method of Example 1, and assembled into a molded lithium ion battery. The discharge capacity after 50 cycles at a current density of 100mA / g is close to 485mAh / g, compared to the Ti without pillar supp...

Embodiment 3

[0028] Take 2.8g Nb 2 Put AlC powder into a beaker, add 20ml of HF solution with a mass fraction of 35%, stir, and etch at room temperature for 18h. Then the etch powder is centrifuged out of Nb 2 C MXene powder, washed with deionization to PH = 6-7, baked in a blast oven at 80°C for 8h. 0.15g dried Nb 2 C MXene powder, stirred in 60mL solution containing 2g / mL chitosan (Aladdin reagent, medium viscosity, 200-400mPa.s) at 60°C for 8h, centrifuged, cleaned with deionization, dried, and then heated in argon atmosphere The carbon pillared Nb was obtained by heating at 600 °C for 2 h at a heating rate of 3 °C / min. 2 C MXene materials. Nb supported by as-prepared carbon pillars 2 The CMXene material is made into electrodes according to the method of Example 1, assembled into a simulated supercapacitor, and the discharge capacity after 3000 cycles at a current density of 10A / g is close to 275F / g, compared to the non-pillared Nb 2 The capacity of C MXene (~95F / g), the capacity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com