Planar fluorescent condenser with scattering particles and fluorescent quantum dots and method for preparing planar fluorescent condenser

A technology of fluorescent quantum dots and scattering particles, which is applied in the field of planar fluorescent concentrators containing scattering particles and copper indium sulfur quantum dots and its preparation, and can solve the problems of restricting the wide application of CIS, complicated preparation process, and low photoelectric conversion efficiency , to achieve the effect of enhancing the light conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

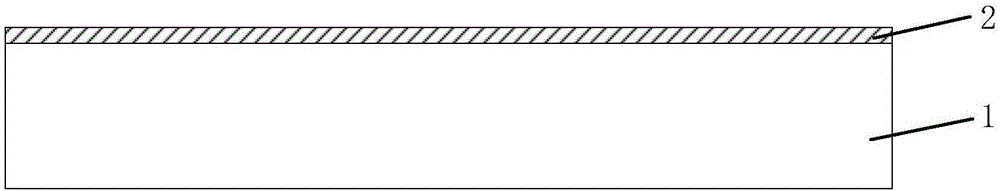

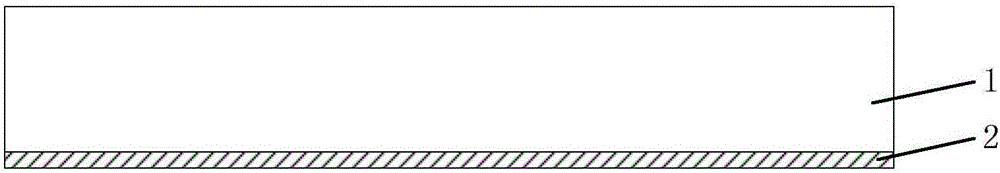

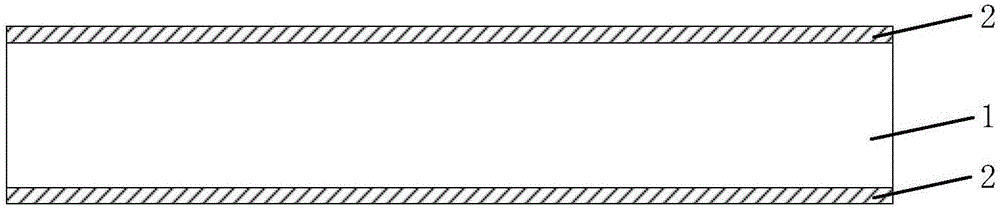

[0072] A method for preparing a planar fluorescent concentrator, the planar fluorescent concentrator includes scattering particles, fluorescent quantum dots and a planar optical waveguide.

[0073] The preparation method of the specific planar fluorescent concentrator includes the following processes:

[0074] (1) Preparation of fluorescent quantum dots. Those skilled in the art can prepare fluorescent quantum dots with reference to the method of prior art, and the preferred method for preparing copper indium sulfur quantum dots (CIS-QDs) is as follows: weigh cuprous iodide (CuI) and indium acetate ( In(Ac) 3 ), added to a three-necked flask, measured excess dodecanethiol (1-dodecanethiol, DDT) and paraffin solution, added to the three-necked flask successively, stirred and mixed evenly. Under the protection of continuous passage of inert gas, the above mixed solution is continuously heated and heated until the mixed solution turns from black to light red, then the heating i...

Embodiment 1

[0084] In this example, the fluorescent material CIS-QDs is synthesized by "One-Pot Reaction". The synthesized CIS-QDs have the characteristics of broadband blue-violet light absorption and broadband red-orange light emission, and can convert blue-violet light Converted to red light, its characteristic spectrum is as Figure 4 shown. The specific implementation process is:

[0085] (a) Weigh 1mmol CuI and 1mmol In(Ac) 3 , into a 50ml three-necked flask, measure 10ml DDT and 20ml liquid paraffin, and add them in turn to the three-necked flask and stir to mix evenly. In the continuous pass there are N 2 Under the protection of the above-mentioned mixed solution, heat the above mixed solution at 200°C for 20 minutes, the solution turns from black to light red, stop heating and quickly cool to room temperature, wash repeatedly with the mixed solution of n-hexane and absolute ethanol to remove impurities, and then vacuum dry to obtain copper Indium sulfur quantum dot (CIS-QDs) ...

Embodiment 2

[0090] In this embodiment, the fluorescent material used is copper indium sulfur quantum dots coated with ZnS on the surface of the core / shell (Core / Shell) structure, and the chemical composition is CuInS 2 / ZnS, naming the copper indium sulfur quantum dots coated with ZnS as CIS / ZS-QDs, the CIS / ZS-QDs of the core-shell structure has the characteristics of high quantum yield and adjustable emission wavelength, by wrapping ZnS, It can convert blue-violet light into red-orange light, and its characteristic spectrum is as follows Figure 5 Shown; The material used in the optical waveguide is granular PMMA. The specific implementation process is:

[0091] (a) Weigh 1mmol Zn(Ac) 2 In the beaker, add 10ml of liquid paraffin, stir and mix evenly, set aside;

[0092] (b) Weigh 1mmol CuI and 1mmol In(Ac) 3 , into a 50ml three-necked flask, measure 15ml DDT and 10ml liquid paraffin, and add them to the three-necked flask in turn to stir and mix evenly. 2 Under the protection of pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com