Recoverable ligand-free mesoporous polymer palladium catalyst and synthetic method and application thereof

The technology of a palladium catalyst and a synthesis method is applied in the directions of organic compound/hydride/coordination complex catalyst, physical/chemical process catalyst, catalytic reaction, etc., and can solve the problems of large particle size, low content and uneven distribution of catalyst metal particles. , to achieve the effect of high catalytic activity and stability, high specific surface area, and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Synthesis of phenolic resin precursor solutions. The specific process is as follows: Weigh the mass of the flask and the magnet, accurately add 8.0g of phenol, and heat in a water bath at 42-45°C to completely melt the phenol and become transparent. Add 1.7 g of the prepared 20% NaOH solution dropwise into the phenol solution. Then, 14.2 g of a 37 wt % formaldehyde solution was added dropwise, followed by reflux at 70° C. for 1 hour. After the reflux is completed, cool to room temperature, adjust the solution to neutrality with 2mol / L HCl, distill under reduced pressure under vacuum at 45-50°C to anhydrous state, and cool to room temperature naturally. Weigh the quality of the product, prepare it as a 20wt% ethanol solution, stir evenly and then centrifuge, the obtained supernatant is the phenolic resin precursor, referred to as PF.

Embodiment 2

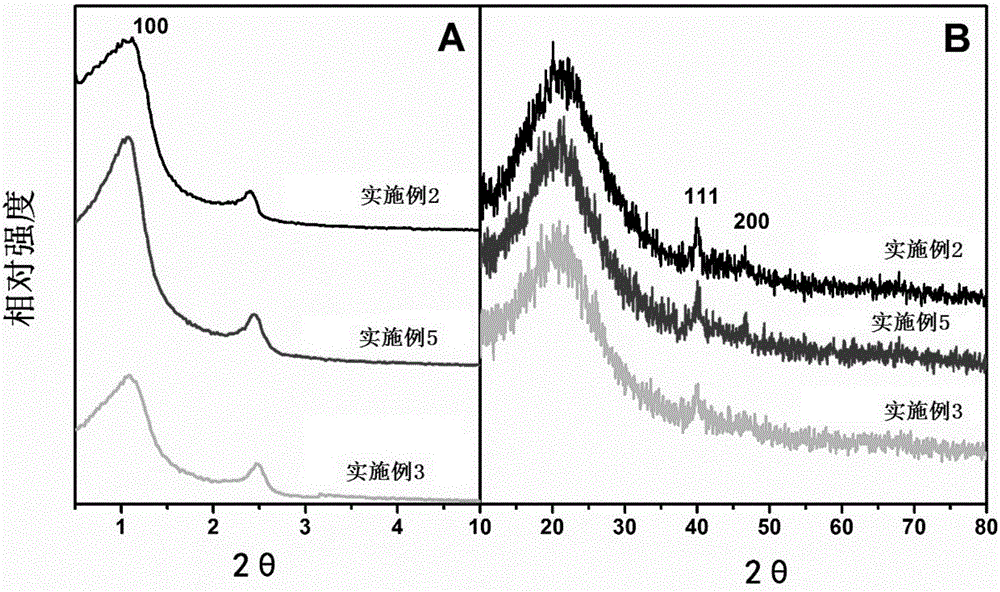

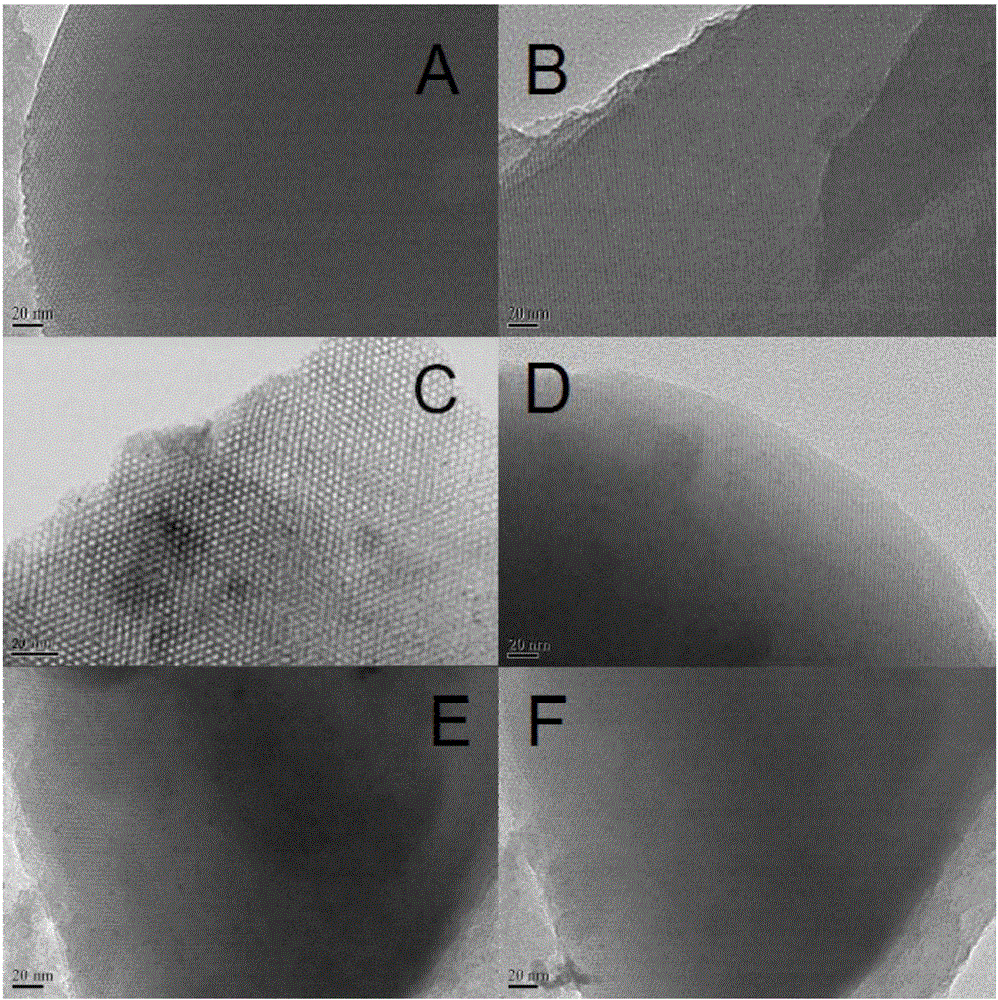

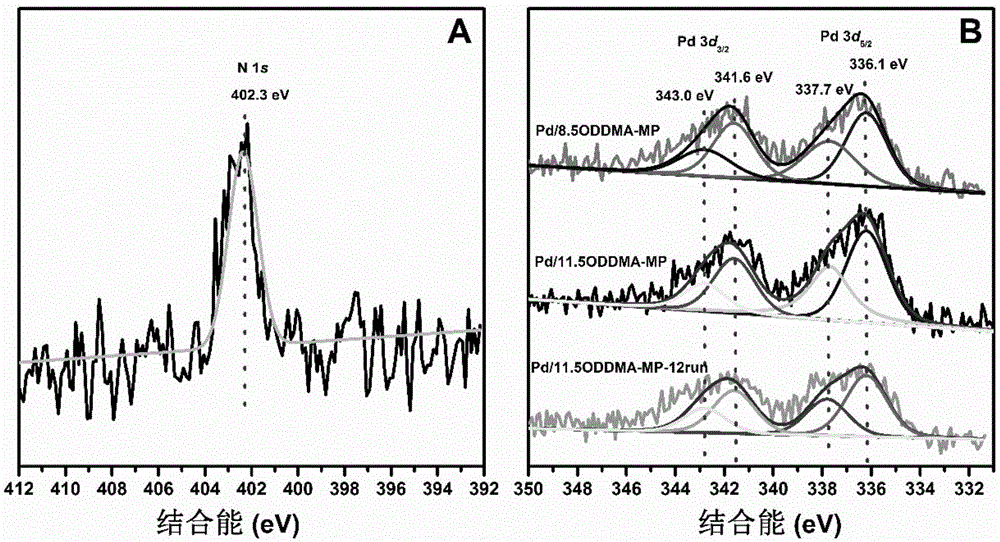

[0041] Synthesis of a recyclable ligand-free mesoporous polymeric palladium catalyst with a Pd content of 1 wt% and an N content of 8.5 wt%. Dissolve 2.4g P123, 2.0g hydrochloric acid in 10.0g ethanol and stir at 40°C for 15min, 3.74g tetraethyl orthosilicate, 1.65g octadecyldimethyl[3-(trimethoxysilyl)propane Base] (ODDMA) ammonium chloride 5.0g ethanol and stirred at 40°C for 15 minutes, then added 20% PF solution and mixed together and continued to stir for 2 hours. The mixed solution is coated with a film, volatilized at room temperature for 5-8 hours, and then placed in an oven for thermal polymerization at 100°C for 24 hours. Scraped film, calcined at 330°C for 5 hours in a high-purity nitrogen atmosphere to obtain an ordered mesoporous material, marked as 8.5ODDMA-MP (8.5 represents the mass percentage of ODDMA functional groups measured by elemental analysis). 2.0mL 0.05g / mL Na 2 PdCl 4 The ethanol solution and 0.3g 8.5ODDMA-MP were stirred at room temperature for 6...

Embodiment 3

[0045] Synthesis of a recyclable ligand-free mesoporous polymer palladium catalyst with a Pd content of 1 wt% and an N content of 11.5 wt%. Dissolve 2.4g P123, 2.0g hydrochloric acid in 10.0g ethanol and stir at 40°C for 15 minutes, 3.74g tetraethylorthosilicate, 1.87g octadecyldimethyl[3-(trimethoxysilyl) Propyl](ODDMA)ammonium chloride 5.0g ethanol was stirred at 40°C for 45 minutes, and then 20% PF solution was added and mixed together to continue stirring for 2 hours. The mixed solution is coated with a film, volatilized at room temperature for 5-8 hours, and then placed in an oven for thermal polymerization at 100°C for 48 hours. Scraped film, calcined at 275°C for 5 hours in a high-purity nitrogen atmosphere to obtain an ordered mesoporous material, marked as 11.5ODDMA-MP (11.5 represents the mass percentage of ODDMA functional groups measured by elemental analysis). 4.0mL 0.05g / mL Na 2 PdCl 4 The ethanol solution was stirred with 0.3g 11.5ODDMA-MP at room temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com