Interdigital electrode material for high temperature surface acoustic wave sensor and the preparation method thereof

A technology of interdigitated electrodes and targets, which is applied to parts of thermometers, instruments, thermometers, etc., can solve problems such as prolonging working time and degradation of electrode materials, and achieve enhanced adhesion, increased temperature tolerance, and improved manufacturing process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

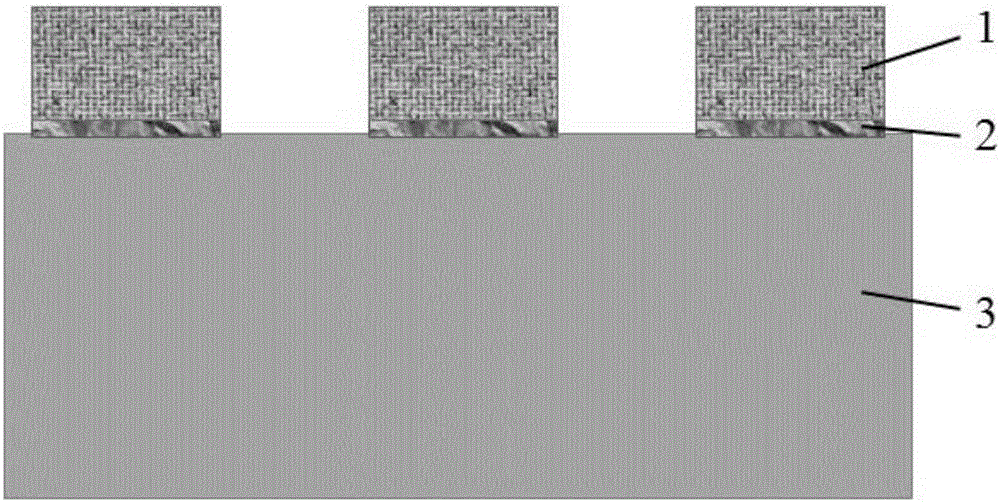

[0048] Embodiment 1, on AlN / sapphire substrate, prepare Ir-Mo / Ta interdigitated electrode

[0049] (1) The AlN / sapphire substrate was ultrasonically cleaned with acetone, alcohol and deionized water for 5 minutes respectively, and then dried with nitrogen, and the cleaned substrate was placed in the electron beam evaporation chamber.

[0050] (2) Vacuum the electron beam evaporation chamber to a background vacuum of 10 -6Below Pa, the distance from the target to the substrate is 60m. Open the autobiography, adjust the electron gun power to be 17%; control the evaporation speed of the Ta electrode material to be Open the baffle, and coat the Ta electrode with a thickness of 10nm; after the coating is finished, let it stand for more than 10 minutes, fill it with nitrogen, and take out the substrate.

[0051] (3) Fix the substrate in step (2) on the substrate stage of magnetron sputtering with iron wire, and put the substrate together with the substrate stage into the vacuum c...

Embodiment 2

[0058] Embodiment 2, in La 3 Ga 5 SiO 14 On the substrate, prepare Ir-Mo / Ta high temperature interdigitated electrode

[0059] (1) La 3 Ga 5 SiO 14 The substrate was ultrasonically cleaned with acetone, alcohol and deionized water for 5 minutes respectively, and then dried with nitrogen, and the cleaned substrate was placed in the electron beam evaporation chamber.

[0060] (2) Vacuum the electron beam evaporation chamber to a background vacuum of 10 -6 Below Pa, the distance from the target to the substrate is 60cm, turn on the autobiography, adjust the power of the electron gun to 17%; control the evaporation speed of the Ta electrode material as Open the baffle; the thickness of the coated Ta electrode is 15nm. After the coating is finished, let it stand still for more than 10 minutes, fill it with nitrogen, and take out the substrate.

[0061] (3) Fix the substrate in step (2) on the substrate stage of magnetron sputtering with iron wire, and put the substrate tog...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com