N,N-dimethyl tetrahydrofurfuryl amine synthesis method

A technology of dimethyltetrahydrofurfurylamine and dimethylfurfurylamine, which is applied in the N field, can solve problems such as difficulty in high-concentration recovery, difficulty in reusing, and easy volatilization of dimethylamine, so as to achieve a clean and efficient hydrogenation system. The effect of high utilization rate of raw materials and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

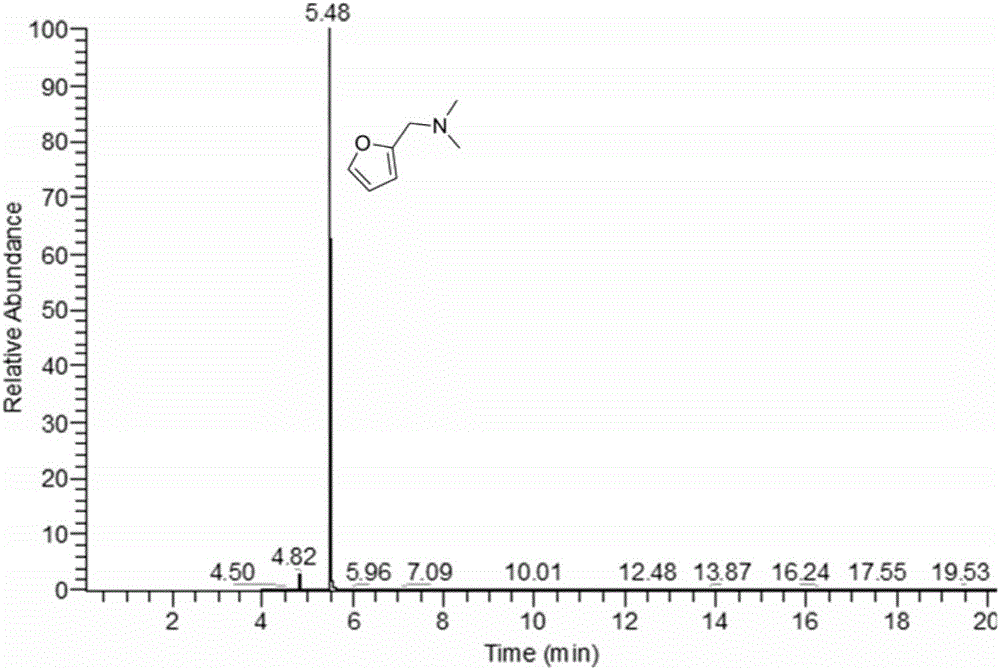

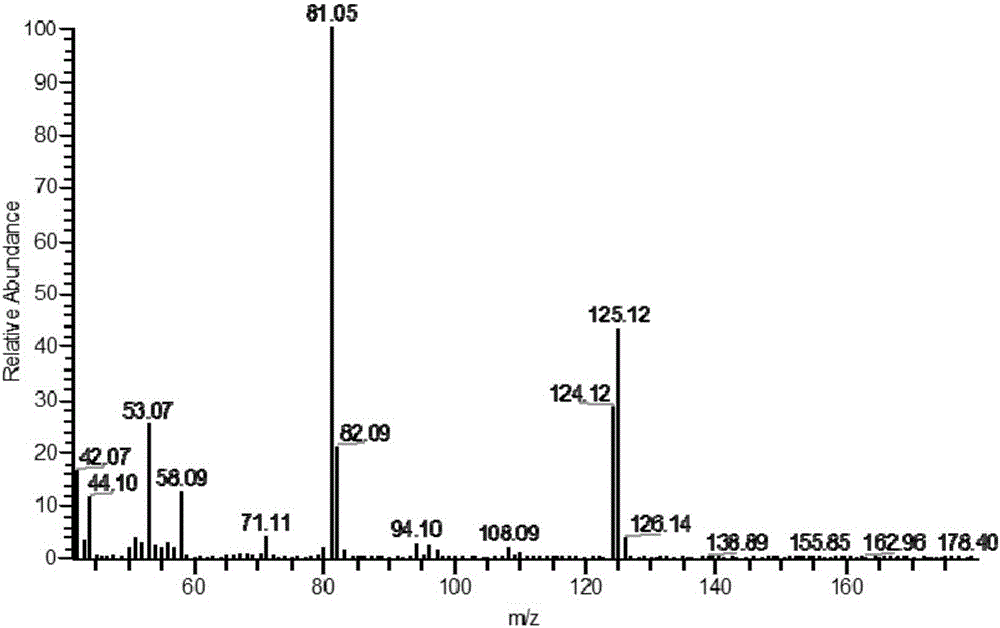

Image

Examples

Embodiment 1

[0020] Add 50g of crushed corncobs, 400g of N,N-dimethylformamide (DMF) and 200g of formic acid into a 1000mL round-bottomed flask, place the flask in an oil bath to stir and heat for reaction, the temperature is 135°C, and the reaction time for 10h. After the reaction was completed, the residue was filtered out, the filtrate was distilled to recover formic acid and DMF, and the residue was distilled under reduced pressure at 52.5-64°C and 2000 Pa to obtain 11.5 g of N,N-dimethylfurfurylamine product. Then add 11.5g of N,N-dimethylfurfurylamine product and 200mL of methanol into a 400mL autoclave, then add 0.2g of catalyst Raney nickel, feed 5.0MPa hydrogen to heat the reaction, the temperature is 180°C, and the reaction time is After 3 hours, the reaction was distilled under atmospheric pressure, the solvent was recovered, and 11.2 g of the N,N-dimethyltetrahydrofurfurylamine product was collected at 155-162 ° C. The product separation mass yield (based on corn cobs) was 22.4...

Embodiment 2

[0022] Add 50g of xylose, 250g of N,N-dimethylformamide (DMF) and 60g of formic acid into a 500mL round-bottomed flask, place the flask in an oil bath, stir and heat for reaction, the temperature is 130°C, and the reaction time is 8h. After the reaction, the residue was filtered out, the filtrate was distilled to recover formic acid and DMF, and the residue was distilled under reduced pressure at 52.5-64°C and 2000 Pa to obtain 32.7g of N,N-dimethylfurfurylamine product with a molar yield of 76%. Then add 32.7g of N,N-dimethylfurfurylamine product and 200mL of methanol into a 400mL autoclave, then add 1.5g of catalyst Raney nickel, feed 10.0MPa hydrogen to heat and react, the temperature is 150°C, and the reaction time is 4h, atmospheric pressure distillation after reaction finishes, reclaims solvent, collects 155~162 ℃ cut N, N-dimethyltetrahydrofurfurylamine product 31.4g, hydrogenation molar yield is 92%, product total molar yield (based on wood sugar) was 69.9%.

Embodiment 3

[0024] Add 50g of furfural, 250g of N,N-dimethylformamide (DMF) and 35g of formic acid into a 500mL round-bottomed flask, place the flask in an oil bath, stir and heat for reaction, the temperature is 130°C, and the reaction time is 10h. After the reaction was completed, the residue was filtered out, the filtrate was distilled to recover formic acid and DMF, and the residue was distilled under reduced pressure at 52.5-64 ° C and 2000 Pa to obtain 56.7 g of N, N-dimethylfurfurylamine product with a molar yield of 86%. Then add 56.7g of N,N-dimethylfurfurylamine product and 200mL of ethanol into a 400mL autoclave, then add 0.2g of catalyst Pd / C, feed 3.0MPa hydrogen to heat the reaction, the temperature is 150°C, and the reaction time is 5h, atmospheric pressure distillation after reaction finishes, reclaims solvent, collects 155~162 ℃ cut N, N-dimethyltetrahydrofurfurylamine product 55.6g, hydrogenation molar yield is 95%, product total molar yield (based on wood sugar) was 81....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com