A kind of powdery pd/sio2 catalyst and its preparation method and application

A catalyst and co-catalyst technology, applied in physical/chemical process catalysts, hydrogenation preparation, chemical instruments and methods, etc., can solve the problems of small specific surface area, poor selectivity, and many side reactions, and achieve high catalytic activity and reduce residence time. Time and less side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

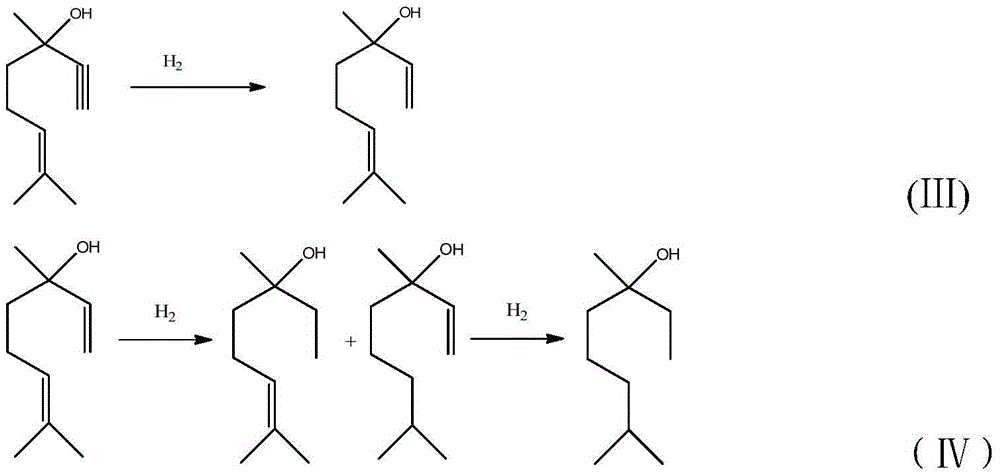

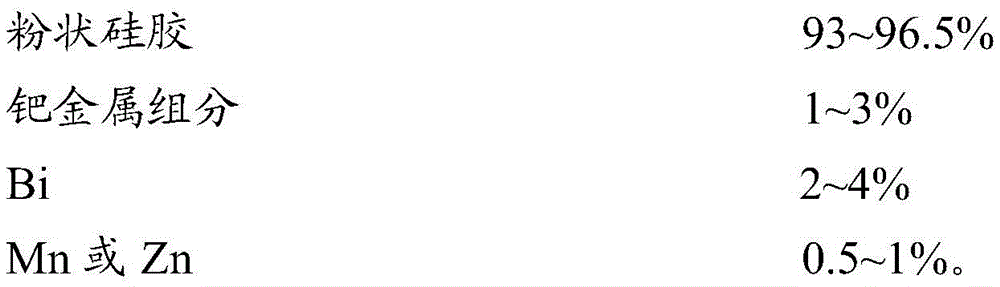

Method used

Image

Examples

preparation example Construction

[0061] Catalyst preparation process (1): (1) Submerge 98.15 g of the dried silica gel carrier in an impregnation solution containing 1.00 g of palladium ions, 0.60 g of lead ions, and 0.25 g of chromium ions, and stir and adsorb at 35°C for 2.5 hours , and then vacuum filtration;

[0062] (2) Dry the filter cake obtained in step (1) in a blast drying oven at 55°C, so that the metal precursor is evenly loaded on the inner and outer surfaces of the silica gel carrier;

[0063] (3) The catalyst dried in step (2) is reduced with hydrazine hydrate, and washed with deionized water until it becomes neutral to obtain catalyst A. The preparation methods of catalysts B and C are similar to those of catalyst A, except that the proportions of various active components are different.

[0064] Catalyst preparation process (2): (1) Immerse 90.95g of the silica gel carrier after treatment and drying in the impregnation solution of 5.00g of palladium ions, 3.20g of bismuth ions, and 0.85g of ...

Embodiment 1

[0071] Catalyst A catalyzes the liquid-phase selective hydrogenation of 3-butyn-2-ol in a 2L tank reactor, at a reaction temperature of 20-35°C, a reaction pressure of 2.0MPa, and a catalyst dosage of 1.2% of the mass of acetylenic alcohol After the reaction is complete, the GC analysis results are: the conversion rate of 3-butyn-2-ol in the raw material is 99.9%, and the enol selectivity in the hydrogenation product is 99.6%.

Embodiment 2

[0073] Catalyst B catalyzes the liquid-phase selective hydrogenation of dehydrolinalool in a 2L tank reactor, and the reaction temperature is 25-60°C, the reaction pressure is 2.0MPa, and the volume ratio of ethanol solvent to dehydrolinalool is 1: 1. Under the condition that the amount of catalyst is 1% of the mass of dehydrolinalool, after the reaction is complete, the GC analysis results are: the conversion rate of dehydrolinalool in the raw material is 100%, and the selectivity of linalool in the hydrogenation product is 99.4% %.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com