Method for utilizing all components of artemisia selengensis straw

A full-component, straw technology, applied in the field of waste biomass resource utilization, can solve the problems of large amount of organic solvent, no consideration of residue resource utilization, low yield, etc., and achieve the effect of easy industrialization and improved utilization value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Take 500g (absolutely dry) Artemisia stalks, put them in a reactor after being crushed through a 40-mesh sieve, add 4000mL of 90% (volume fraction) methanol aqueous solution, heat in a water bath at 60°C for 1h, collect the extract by filtration, and filter the filtrate to Press and concentrate to dryness to obtain the extract extract; redissolve the obtained Artemisia stalk extract extract with deionized water as a sample solution, and add it to a macroporous resin column (HPD-600 or AB-8). After reaching adsorption equilibrium (at a temperature of 20° C.), wash the column with 2BV of deionized water, then carry out isocratic elution with an ethanol solution with a volume fraction of 30%, collect the ethanol eluate, and concentrate the eluate under reduced pressure to nothing. Alcoholic smell, to obtain a concentrated eluent; the obtained concentrated eluent was mixed with an equal volume of ethyl acetate, extracted 3 times, and the aqueous phase and ethyl acetate phase...

Embodiment 2

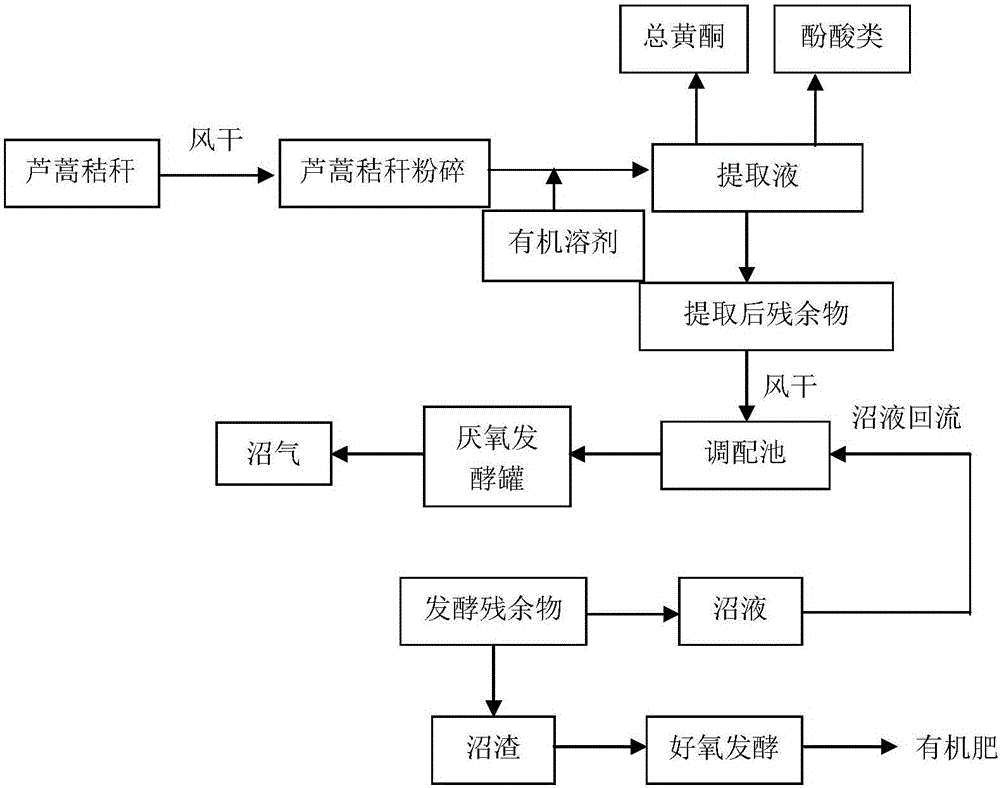

[0036] as attached figure 1 As shown in the process flow, take 1 ton of air-dried artemisia stalks, put them in a reactor after being crushed through a 40-mesh sieve, and place them in a reactor according to the liquid-solid ratio of 12:1 (m 3 / ton) add methanol solution with a volume fraction of 50%, heat in a water bath at 90°C for 4h, filter and collect the extract, and concentrate the filtrate to dryness under reduced pressure to obtain the extract; Reconstitute with water as the sample solution, add it to the macroporous resin column (HPD-600 or AB-8), when the adsorption equilibrium is reached (at a temperature of 20°C), wash the column with 5BV deionized water, and use a volume fraction of Carry out isocratic elution with 50% ethanol solution, collect the ethanol eluate, concentrate the eluate under reduced pressure until it has no alcohol smell, and obtain a concentrated eluate; the obtained concentrated eluate is mixed with an equal volume of ethyl acetate, Extract ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com