Method using laser interference to induce electrochemical deposition so as to prepare periodic and patterned Fe3O4 nano particles

A technology of laser interference and nano-particles, which is applied in nano-technology, electrodes, electrolytic coatings, etc., can solve the problems that nano-materials cannot meet the needs of performance research, fine application, rough particle size distribution, etc., and achieve low preparation costs, simple equipment, and raw materials. Easy to get effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in combination with specific embodiments.

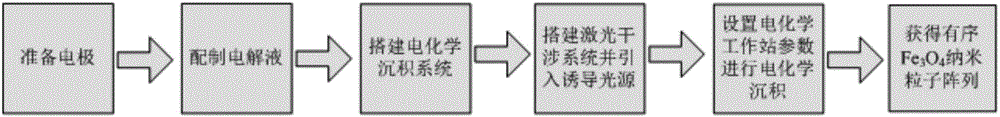

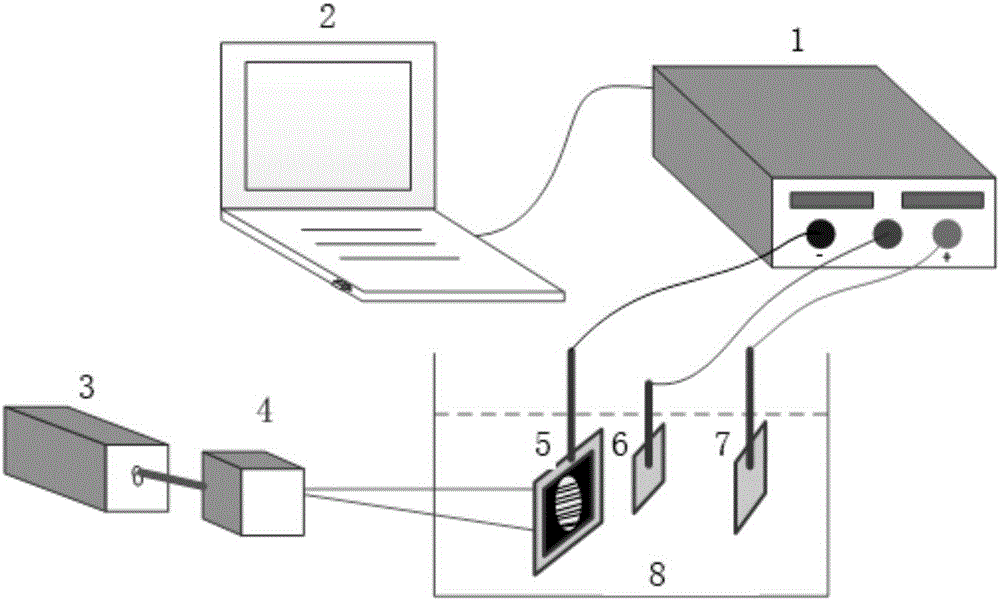

[0034] like figure 1 As shown, the present invention adopts simple laser interference induced electrochemical deposition to prepare patterned Fe 3 o 4 The nanoparticle method is as follows:

[0035] (1) Electrode preparation: the ITO conductive substrate coated with hydrogenated amorphous silicon (a-Si:H) thin film was used as the working electrode; the high-purity iron sheet was used as the counter electrode; the calomel electrode was used as the reference electrode. The surface area of the ITO conductive substrate is 1cm 2 , the square resistance is 4Ω, the thickness of the ITO film is 500nm, and the transmittance is 84%; the hydrogenated amorphous silicon (a-Si:H) film is deposited on the surface of ITO by PECVD method, the thickness is 500nm, and the dark state conductivity is 5E- 10S / cm, the photoelectric conductivity under AM1.5G light conditions is about 7E-5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com