A kind of composite amorphous powder precursor for magnetic powder core and preparation method thereof

An amorphous powder and precursor technology, which is applied in the fields of magnetic objects, inductor/transformer/magnet manufacturing, magnetic materials, etc., can solve the problems of poor thermal stability of magnetic powder cores, and achieve the effect of excellent magnetic properties and good calendering.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

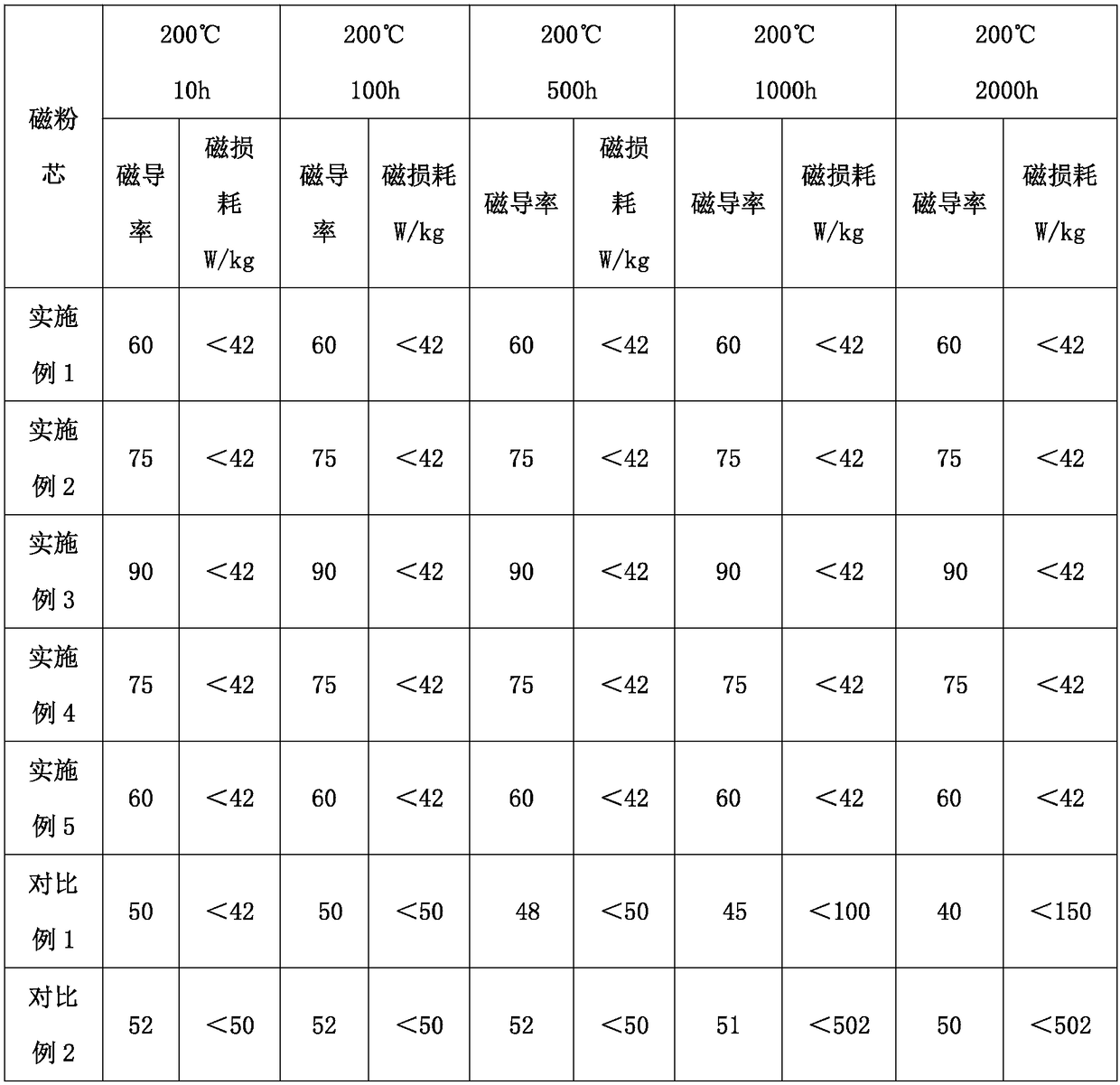

Examples

Embodiment 1

[0057] This embodiment provides a composite amorphous powder precursor for magnetic powder cores and a preparation method thereof, and the corresponding preparation method includes the following steps:

[0058] S1, preparation of amorphous alloy powder:

[0059] S11, the thickness is 18μm, the bandwidth is 10mm, and the composition is Fe 80 Si 9 B 11 The iron-based amorphous alloy thin strip is crushed into 50-200-mesh fragments by a mechanical crusher;

[0060] S12. Put 50-mesh to 200-mesh fragments in a nitrogen-protected atmosphere rotary furnace, and heat-treat at 300°C for 1 hour. During the heat treatment, control the rotation rate of the atmosphere rotary furnace to 5r / min and the atmosphere pressure to 0.1MPa. Stop and turn the atmosphere rotary furnace so that the amorphous fragments are evenly heated;

[0061] S13. Put the heat-treated fragments into an airflow grinder, control the output power of the airflow grinder to 35KW, grind for 50 minutes, and further rou...

Embodiment 2

[0066] This embodiment provides a composite amorphous powder precursor for magnetic powder cores and a preparation method thereof, and the corresponding preparation method includes the following steps:

[0067] S1, preparation of amorphous alloy powder:

[0068] S11, the thickness is 20μm, the bandwidth is 20mm, and the composition is Fe 78 Si 9 B 13 The iron-based amorphous alloy thin strip is crushed into 50-200-mesh fragments by a mechanical crusher;

[0069] S12. Put 50-mesh to 200-mesh fragments in an atmosphere rotary furnace protected by argon, and heat-treat at 300°C for 1 hour. During the heat treatment, control the rotation rate of the atmosphere rotary furnace to 10r / min and the atmosphere pressure to 0.2MPa. Stop and turn the atmosphere rotary furnace so that the amorphous fragments are evenly heated;

[0070] S13. Put the heat-treated fragments into an airflow grinder, control the output power of the airflow grinder to 70KW, grind for 50min, and further round ...

Embodiment 3

[0075] This embodiment provides a composite amorphous powder precursor for magnetic powder cores and a preparation method thereof, and the corresponding preparation method includes the following steps:

[0076] S1, the preparation of amorphous alloy powder:

[0077] S11, the thickness is 25μm, the bandwidth is 30mm, and the composition is Fe 80 Si 9 B 11 The iron-based amorphous alloy thin strip is crushed into 50-200-mesh fragments by a mechanical crusher;

[0078] S12. Put the 50-mesh to 200-mesh fragments in a nitrogen-protected atmosphere rotary furnace, and heat-treat at 280°C for 1h. During the heat treatment, control the rotation rate of the atmosphere rotary furnace to 20r / min, and the atmosphere pressure to 0.3MPa. Turn over the atmosphere rotary furnace to make the amorphous fragments heated evenly;

[0079] S13. Put the heat-treated fragments into an airflow grinder, control the output power of the airflow grinder to 50KW, grind for 90 minutes, and further round...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com