Crystalline silicon solar cell grid line, electrode and back surface field manufacturing process

A technology for solar cells and crystalline silicon cells, applied in the field of solar power generation, can solve the problems of inability to reach 15 μm, complex manufacturing process, affecting cross-sectional area, etc., and achieve the effects of high photoelectric conversion efficiency, low raw material cost, and large light transmission area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

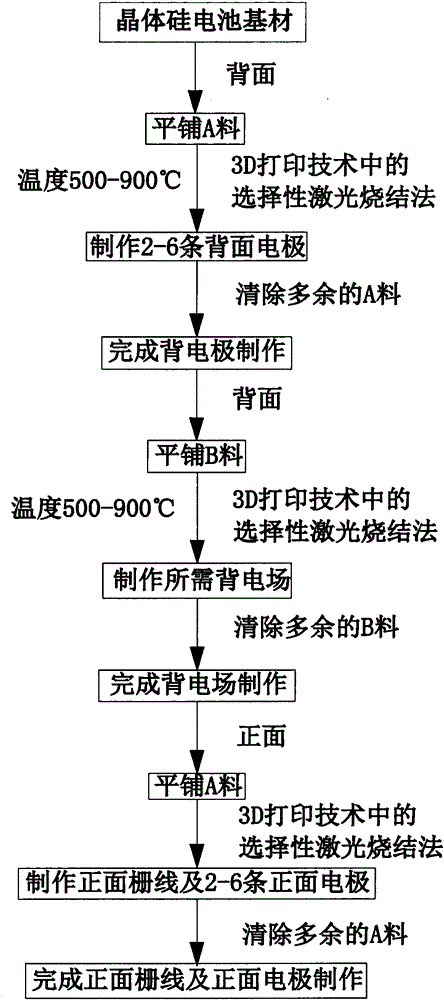

[0031] Embodiment 1: A kind of manufacturing process of crystalline silicon solar cell grid line, electrode, back electric field, it carries out according to following steps:

[0032] Step I: selection of the base material: the present invention selects the crystalline silicon battery that has been processed by processes such as texturing, chemical cleaning, diffusion, etching, dephosphorization, and PECVD as the base material;

[0033] Step II: the production of material A and material B: the present invention uses material A to replace the silver paste in the existing process, and material B to replace the aluminum paste in the existing process. The material A has a high expansion coefficient, low melting point, transparent Glass-ceramic powder with good light properties and silver powder are mixed in a certain proportion. The ratio of silver powder to glass-ceramic powder is 9:1. Material B is made of glass-ceramic powder and aluminum powder in a certain proportion. Aluminum...

Embodiment 2

[0038] Embodiment 2: A kind of manufacturing process of crystalline silicon solar cell grid line, electrode, back electric field, it is carried out according to following steps:

[0039] Step I: selection of the base material: the present invention selects the crystalline silicon battery that has been processed by processes such as texturing, chemical cleaning, diffusion, etching, dephosphorization, and PECVD as the base material;

[0040] Step II: the production of material A and material B: the present invention uses material A to replace the silver paste in the existing process, and material B to replace the aluminum paste in the existing process. The material A has a high expansion coefficient, low melting point, transparent Glass-ceramic powder with good light properties and silver powder are mixed in a certain proportion. The ratio of silver powder to glass-ceramic powder is 18:1. Material B is made of glass-ceramic powder and aluminum powder in a certain proportion. The...

Embodiment 3

[0045]Embodiment 3: a kind of manufacturing process of crystalline silicon solar cell grid line, electrode, back electric field, it is carried out according to following steps:

[0046] Step I: selection of the base material: the present invention selects the crystalline silicon battery that has been processed by processes such as texturing, chemical cleaning, diffusion, etching, dephosphorization, and PECVD as the base material;

[0047] Step II: the production of material A and material B: the present invention uses material A to replace the silver paste in the existing process, and material B to replace the aluminum paste in the existing process. The material A has a high expansion coefficient, low melting point, transparent Glass-ceramic powder with good light properties and silver powder are mixed in a certain proportion. The ratio of silver powder to glass-ceramic powder is 14:1. Material B is made of glass-ceramic powder and aluminum powder in a certain proportion. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com