Pine pollen composition with defaecation improving effect and preparation method of pine pollen

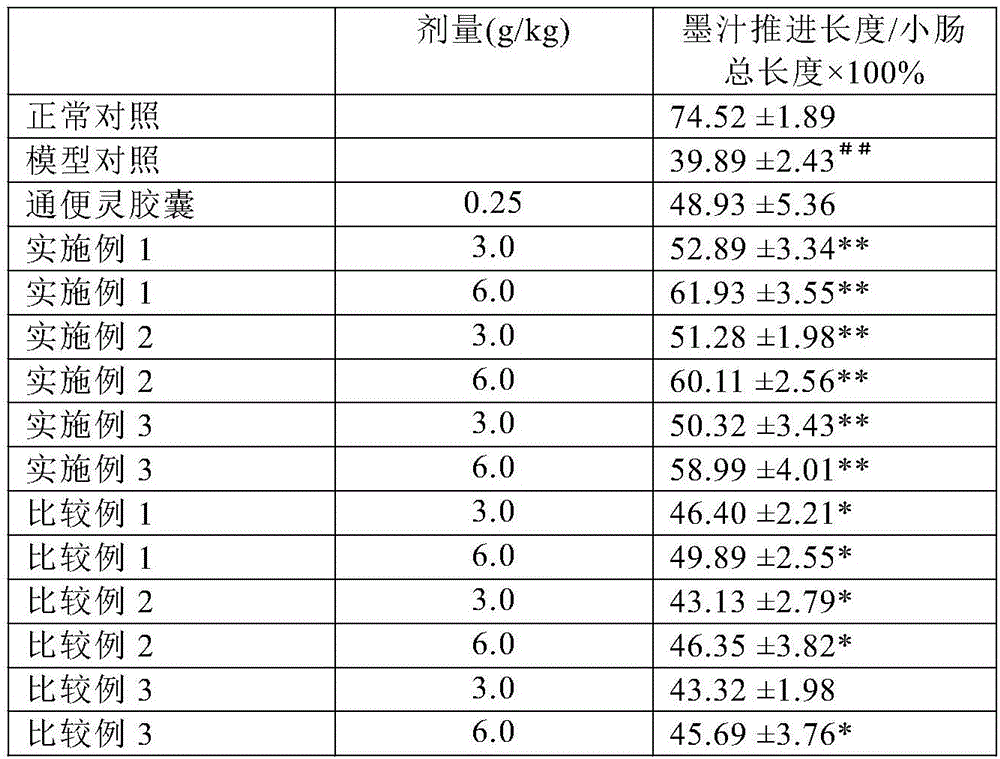

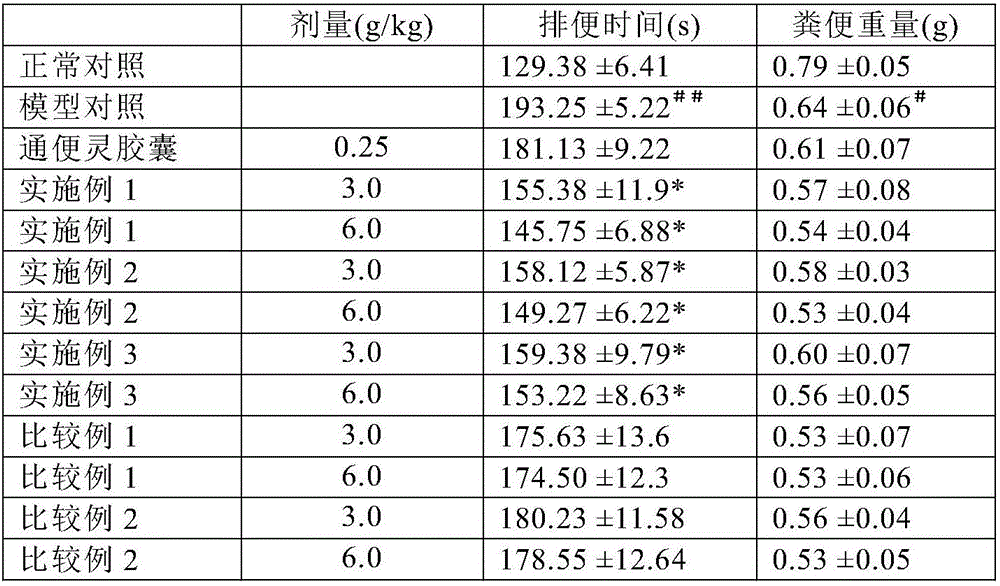

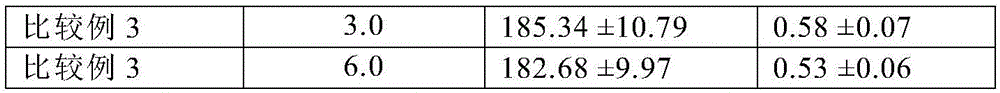

A composition and technology of pine pollen, applied in medical preparations containing active ingredients, drug combinations, food science, etc., can solve the problems of long-term conditioning that is not suitable for people with chronic constipation, failure to prevent constipation, frequent recurrence of constipation symptoms, etc. , to achieve the effect of increasing ink propulsion rate, reducing defecation time, and improving gastrointestinal function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0034] The broken wall pine pollen used in the following examples is commercially available, and the preparation method of each extract is as follows:

[0035] (1) The preparation method of dandelion extract is as follows:

[0036] Take dandelion decoction pieces, add 8 times the weight of water for the first time to decoct twice, the first time for 1 hour, and the second time add 8 times the weight of water for 1 hour, combine the second decoction, filter, and the filtrate is concentrated to A clear paste with a relative density of 1.08-1.10 (80°C), stirred evenly, spray-dried, and mixed evenly to obtain. About 11g of dandelion Chinese herbal decoction pieces are used to prepare 1g of extract.

[0037] (2) The preparation method of Sophora japonica extract is as follows:

[0038] Take Sophora japonica decoction pieces, add 8 times the weight of water to decoct for 1 hour for the first time, add 8 times the weight of water for 1 hour for the second time, combine the second d...

Embodiment 1

[0045] Embodiment 1: Composition (1) with improving laxative effect

[0046] (1) Composition of raw materials: pine pollen, 210 parts by weight; Dandelion extract, 110 parts by weight; Sophora japonica extract, 90 parts by weight; Bitter almond extract, 20 parts by weight; Bamboo leaf extract, 20 parts by weight; Thing, 8 parts by weight; Xylooligosaccharide, 270 parts by weight.

[0047] Excipients: lactose, 10 parts by weight; maltodextrin, 480 parts by weight.

[0048] (2) Preparation steps:

[0049] Weigh the above-mentioned raw materials respectively, and then mix the components with similar weight ratios from small to large in equal volume, fully stir evenly, use 75% ethanol as a binder, and make a soft material, pass the above-mentioned soft material through a 14-mesh screen Granules are made in a swing granulator, and the granules are placed in a multi-functional boiling dryer, boiled and dried at 50°C for about 40 minutes, and the moisture content of the granules is...

Embodiment 2

[0050] Embodiment 2: Composition (two) with improving laxative effect

[0051] (1) Composition of raw materials: pine pollen, 185 parts by weight; Dandelion extract, 130 parts by weight; Sophora japonica extract, 110 parts by weight; Bitter almond extract, 25 parts by weight; Bamboo leaf extract, 25 parts by weight; Thing, 10 parts by weight; Xylooligosaccharide, 230 parts by weight.

[0052] Excipients: magnesium stearate, 22 parts by weight; isomaltulose, 317 parts by weight; konjac flour, 142 parts by weight.

[0053] (2) Preparation steps:

[0054] Weigh the above-mentioned raw materials respectively, and then mix the components with similar weight ratios from small to large in equal volume, fully stir evenly, use 70% ethanol as a binder, and make a soft material, pass the above-mentioned soft material through a 14-mesh screen Granules are made in a swing granulator, and the granules are placed in a multi-functional boiling dryer, boiled and dried at 45°C for about 40 mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com