Calcium magnesium silicate porous ceramic ball ocularprosthesis seat and preparation method thereof

A technology of porous ceramic balls and magnesium silicate, applied in the field of medical biomaterials, can solve the problems of slow vascularization efficiency, exposure of prosthetic eye seat, limited biological activity, etc., to achieve the effect of facilitating cell migration and reducing complex problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

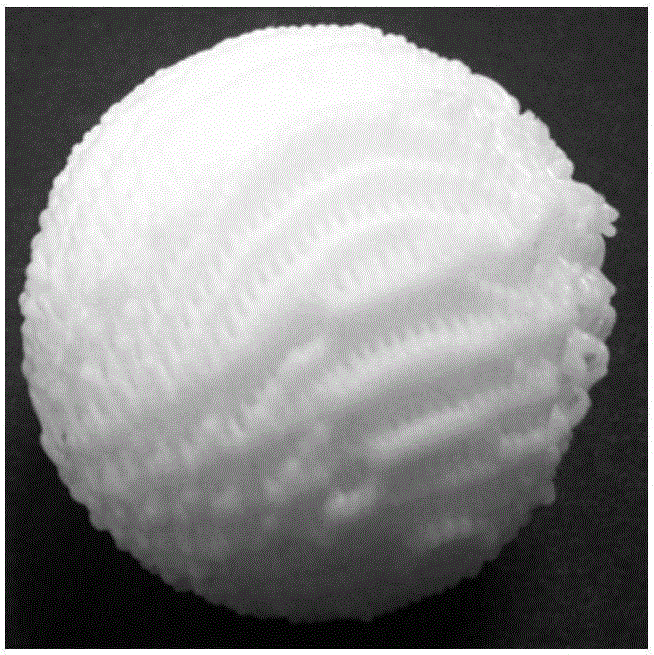

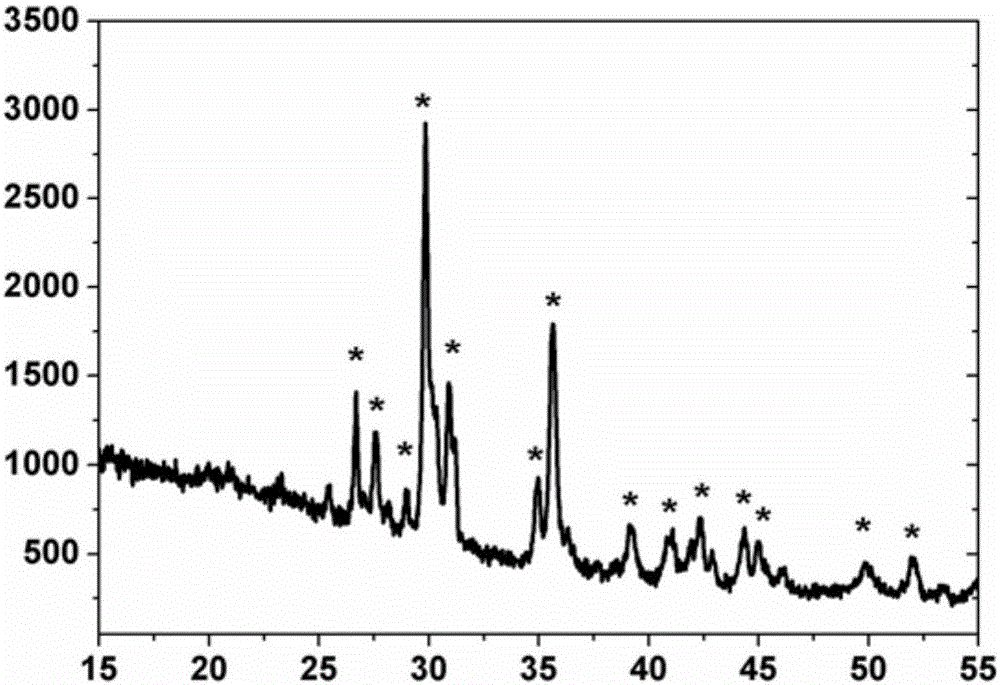

Embodiment 1

[0044] 1) Put the diopside powder into a ball mill and mill it for 4 hours, sieve with a sieve to obtain an ultrafine diopside powder below 60 μm, and then stir and disperse the ultrafine powder in a solid-to-liquid mass ratio of 1:2 In the polyvinyl alcohol aqueous solution with a concentration of 8%, a two-phase uniform paste is formed, and then the paste is placed in the injection reservoir of the three-dimensional printer connected to the tubular nozzle, and then the three-dimensional printer is started, according to the preset square channel and The diameter is three-dimensionally printed to form a spherical porous composite material with a diameter of 24mm, and then the porous composite material is dried at 60°C for 12 hours and sintered at 1350°C for 8 hours to obtain diopside porous ceramic balls. After testing, sintering The diameter of the final ceramic ball is 22mm, and the channel size is 800μm. figure 1 The appearance shown in the XRD test proves that the sintered...

Embodiment 2

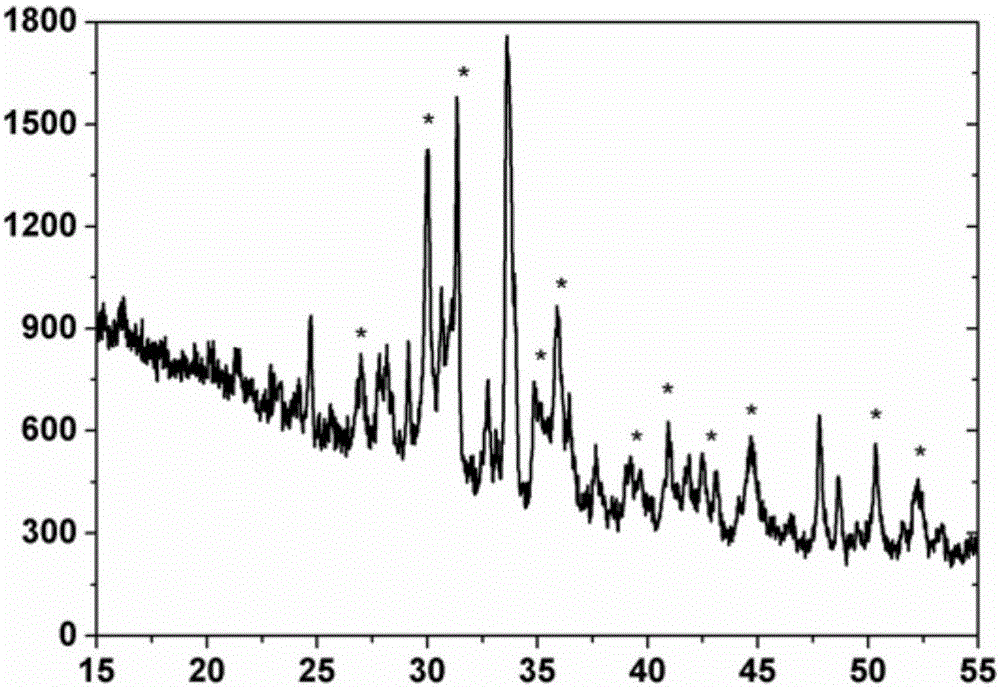

[0048] The preparation method is the same as that in Example 1, the difference is that the composition of the raw materials for preparing the calcium-magnesium silicate modified layer in step 2) is adjusted to: dissolve 0.40 mol of tetraethyl orthosilicate in 400 ml of deionized water, then add 8 ml of nitric acid and stir After 90 minutes, add 0.7mol calcium nitrate and 0.1mol magnesium nitrate, stir and hydrolyze for 90 minutes at room temperature, age for 12 hours, the mixed solution is converted into a hydrogel, and the diopside porous ceramic ball prepared in step 1) is placed in the In the gel, impregnate with negative pressure suction, take out the porous ceramic ball after standing for 8 minutes, then use vacuum filtration for 2 minutes to suck out the excess gel in the pores, continue to age for 36 hours, dry at 95°C for 24 hours, and then calcined at 1200°C for 1 Hours, cool down naturally. After testing, the surface of the diopside porous ceramic ball pore wall has ...

Embodiment 3

[0051] The preparation method is the same as in Example 1, the difference is that the composition of the raw materials for preparing the calcium-magnesium silicate modified layer in step 2) is adjusted to: dissolve 0.20 mol of tetraethylorthosilicate in 90 ml of deionized water, then add 3 ml of nitric acid and stir After 40 minutes, add 0.3mol calcium nitrate and 0.1mol magnesium nitrate, stir and hydrolyze for 60 minutes at room temperature, age for 2 hours, the mixed solution is converted into a gel, and the diopside porous ceramic ball prepared in step 1) is placed in the gel. In the glue, negative pressure suction impregnation, after standing for 5 minutes, take out the porous ceramic ball, then use vacuum filtration for 5 minutes to suck out the excess gel in the pores, continue to age for 36 hours, dry at 95°C for 36 hours, and then calcinate at 1000°C for 2 hours , natural cooling. After testing, the surface of diopside porous ceramic ball channel wall layered with a t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com