3D printed sodium alginate-type I collagen-ceramic composite scaffold, preparation method and application

A sodium alginate and 3D printing technology, which is applied in prosthesis, tissue regeneration, additive processing, etc., can solve problems such as the inability to bear the huge stress of the knee joint, poor mechanical properties of fibrocartilage, and inability to guarantee long-term curative effect, and achieve improved Chondrocyte proliferation and ALP activity, reduce chronic inflammatory response, and facilitate cell adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

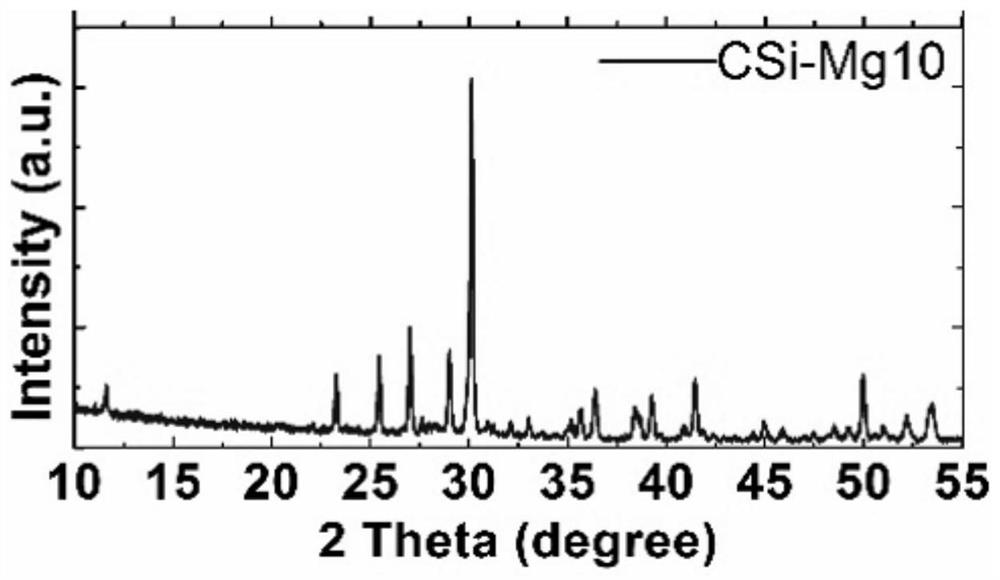

[0039] 1) The calcium magnesium silicate powder is processed by wet ball milling to obtain an ultrafine powder with a particle size of no more than 5 μm, and the ultrafine powder is dispersed in deionized water, stirred at room temperature for 1 hour, and then added with I The type collagen powder was stirred at room temperature for 5 minutes, and finally sodium alginate was added and stirred at room temperature for 15 minutes to make a hydrogel as a composite material ink;

[0040] Among them, the mass fraction ratio of sodium alginate: type I collagen: calcium magnesium silicate is 6:2:5.

[0041] The calcium-magnesium silicate is magnesium-doped wollastonite, and the molar percentage of magnesium replacing calcium in the magnesium-doped wollastonite is 10%.

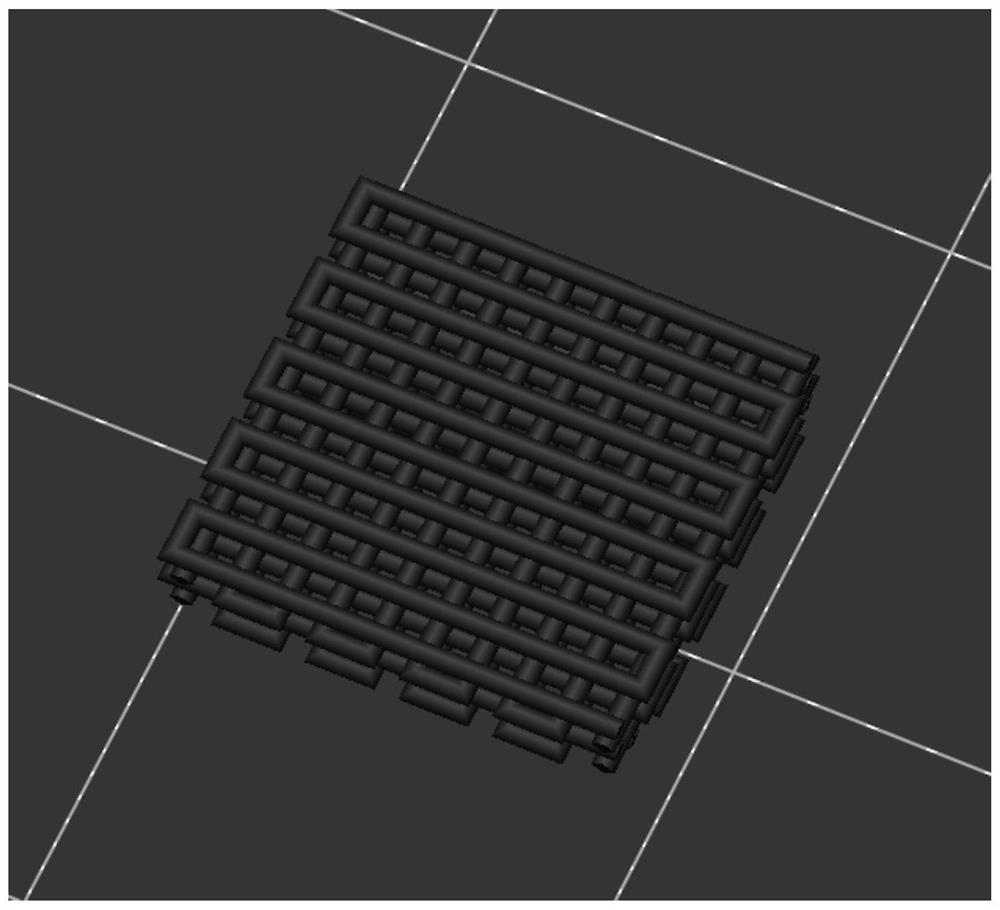

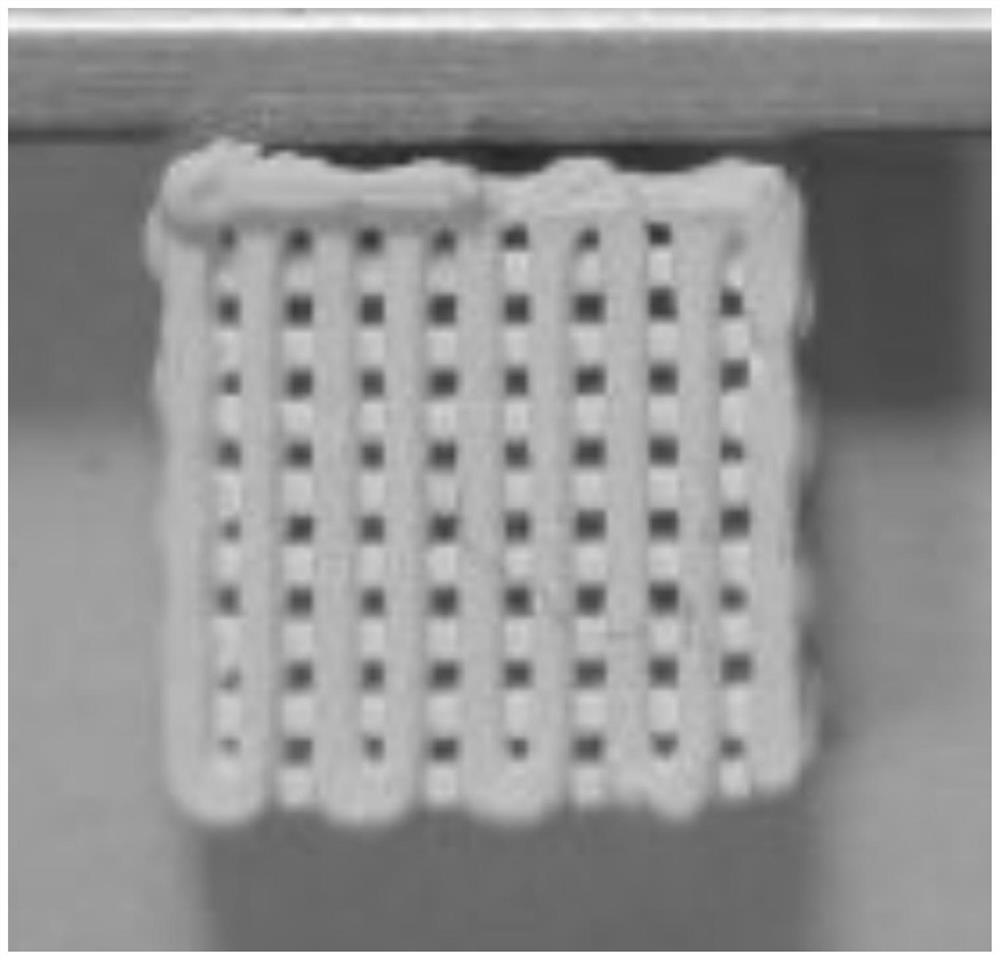

[0042] 2) Put the hydrogel into a three-dimensional printer and print it with a three-dimensional printer. The length of the scaffold is 10 mm, the pore size of the channel is 300 μm, and the porosity is 43%. During ...

Embodiment 2

[0045] 1) Treat the β-tricalcium phosphate powder with wet ball milling to obtain an ultrafine powder with a particle size of no more than 5 μm, disperse the ultrafine powder into deionized water, and stir at room temperature for 1 hour, then add I The type collagen powder was stirred at room temperature for 5 minutes, and finally sodium alginate was added and stirred at room temperature for 15 minutes to make a hydrogel as a composite material ink;

[0046] The mass fraction ratio of sodium alginate: type I collagen: β-tricalcium phosphate is 6:2:5.

[0047] 2) Put the hydrogel into a three-dimensional printer and print it with a three-dimensional printer. The length of the scaffold is 10 mm, the pore size of the channel is 300 μm, and the porosity is 43%. During the printing process, 10% calcium chloride spray was used for cross-linking. After printing, the scaffold was soaked in 10% calcium chloride solution for 10 minutes for further cross-linking to obtain the final 3D p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com