Method for preparing doping type carbon dioxide adsorbent ceramic

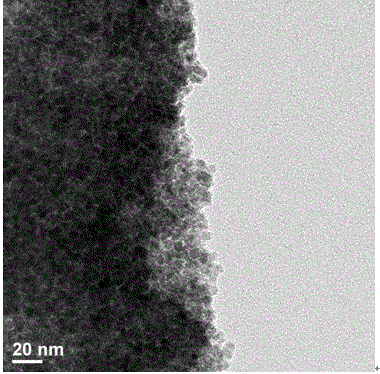

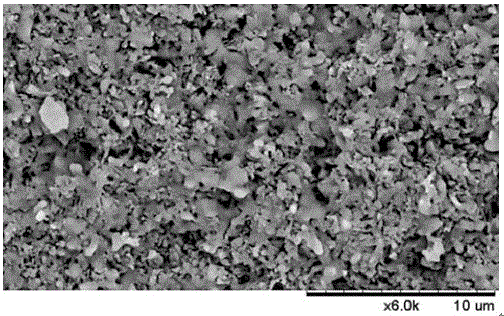

A carbon dioxide and adsorbent technology, applied in the field of preparing doped carbon dioxide adsorbent ceramics, can solve problems such as low adsorption efficiency, and achieve the effects of uniform distribution, high degree of crystallization and fine size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for preparing doped carbon dioxide adsorbent ceramics, characterized in that: comprising the following preparation steps:

[0029] (1) Raw materials are mixed, the silicon source is TEOS, the lithium source is lithium nitrate; the alcohol solvent is benzyl alcohol, and all raw materials are high-purity raw materials with a purity of more than 99.9%; Measure and proportion the ingredients, mix them with the alcohol solvent at room temperature, and stir them mechanically for 2 hours to obtain a uniform alcohol solution;

[0030] (2) Mix the above-mentioned homogeneous alcohol solution and the surfactant polyethylene glycol 2000 in a pre-reaction chamber, and then perform a pre-reaction, the temperature of the pre-reaction is 180 degrees Celsius, and the pre-reaction time is 2 hours to obtain a pre-reaction liquid;

[0031] (3) Then transport the pre-reaction liquid to the reaction chamber for alcohol thermal reaction, the reaction temperature is 250 degrees Celsi...

Embodiment 2

[0035] A method for preparing doped carbon dioxide adsorbent ceramics, characterized in that: comprising the following preparation steps:

[0036](1) Raw materials are mixed, the silicon source is TEOS, the lithium source is lithium nitrate; the alcohol solvent is benzyl alcohol, and all raw materials are high-purity raw materials with a purity of more than 99.9%; Measure and proportion the ingredients, mix them with the alcohol solvent at room temperature, and stir them mechanically for 2 hours to obtain a uniform alcohol solution;

[0037] (2) Mix the above-mentioned homogeneous alcohol solution and the surfactant polyethylene glycol 2000 in a pre-reaction chamber, and then perform a pre-reaction, the temperature of the pre-reaction is 170 degrees Celsius, and the pre-reaction time is 2 hours to obtain a pre-reaction liquid;

[0038] (3) Then transport the pre-reaction liquid to the reaction chamber for alcohol thermal reaction, the reaction temperature is 250 degrees Celsiu...

Embodiment 3

[0042] A method for preparing doped carbon dioxide adsorbent ceramics, characterized in that: comprising the following preparation steps:

[0043] (1) Raw materials are mixed, the silicon source is TEOS, the lithium source is lithium nitrate; the alcohol solvent is benzyl alcohol, and all raw materials are high-purity raw materials with a purity of more than 99.9%; Measure and proportion the ingredients, mix them with the alcohol solvent at room temperature, and stir them mechanically for 2 hours to obtain a uniform alcohol solution;

[0044] (2) Mix the above-mentioned homogeneous alcohol solution and the surfactant polyethylene glycol 2000 in a pre-reaction chamber, and then perform a pre-reaction, the temperature of the pre-reaction is 190 degrees Celsius, and the pre-reaction time is 1 hour to obtain a pre-reaction liquid;

[0045] (3) The pre-reaction solution is then transported to the reaction chamber for alcohol thermal reaction at a reaction temperature of 260 degrees...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com