Molybdenum sulfide-based nano-material for high-efficiency photocatalytic preparation of hydrogen and preparation method thereof

A nanomaterial, molybdenum sulfide technology, applied in the field of catalysis, can solve the problem of low plasma-enhanced catalysis efficiency, and achieve the effect of remarkable catalysis effect, easy customer service, and high catalysis efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

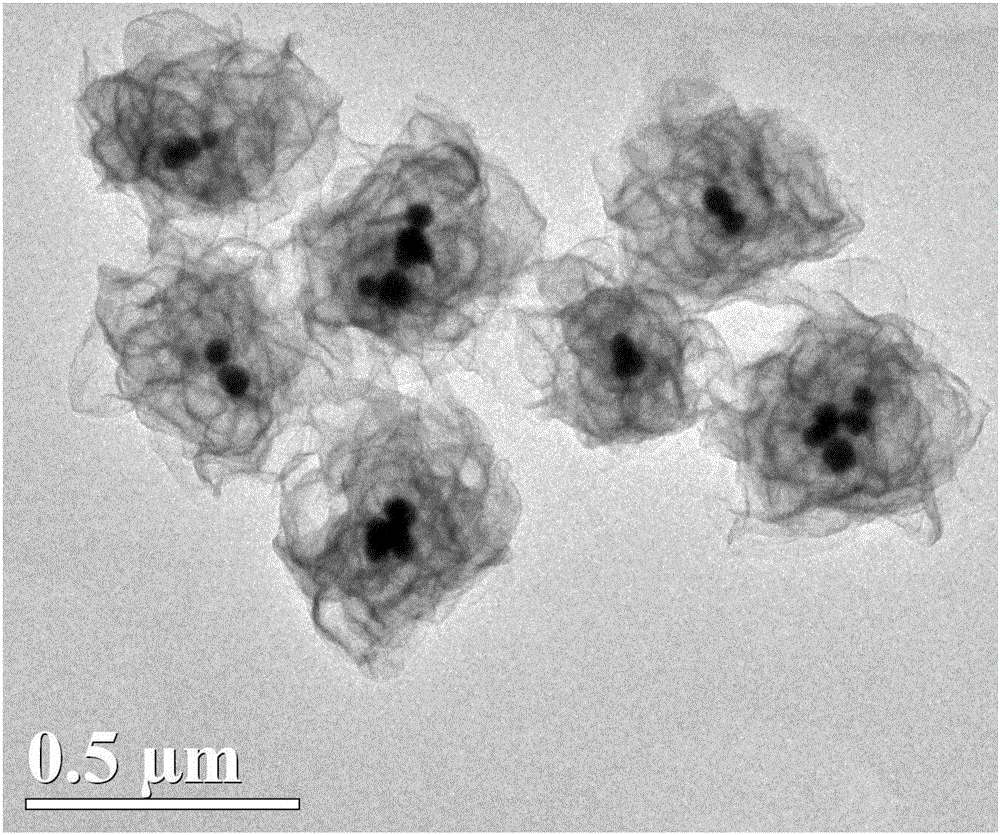

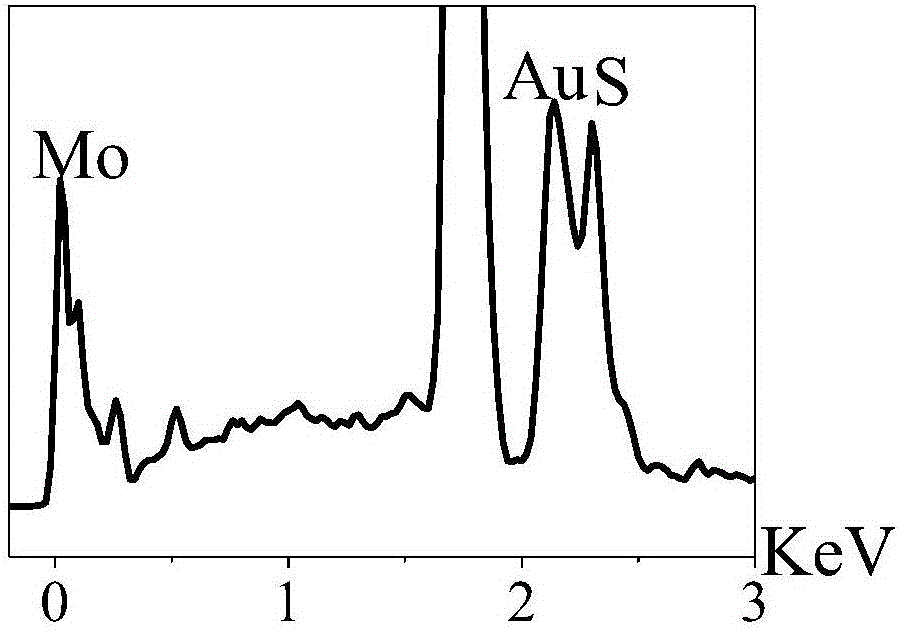

[0021] Mix 200 μl of chloroauric acid solution (50 mg / ml) with 100 ml of deionized water, heat to boiling, then add dropwise 700 μl of sodium citrate solution (1 wt %), and heat for 10 minutes to obtain a gold nanoparticle solution. 0.5 g of cysteine was dissolved in 100 ml of deionized water to obtain solution A. Dissolve 0.5-1.0 g of sodium molybdate in 100 ml of deionized water to obtain solution B. Solution A and solution B were mixed and sonicated for 2-4 hours at a volume ratio of 2:1. Add 40-80ml of gold nanoparticle solution into 10ml of 1% polyethylene glycol solution, and then mix with the above-mentioned ultrasonic mixture of A and B, and then carry out hydrothermal reaction at 200°C for 10h. After the reaction, the solution was dried in an oven at 110°C for 24 hours to obtain a gold nanoparticle / molybdenum sulfide core-shell nanomaterial.

[0022] Characterization: Take 0.1 g of gold nanoparticles / molybdenum sulfide core-shell nanomaterials and disperse them in...

Embodiment 2

[0024] Mix 200 μl of chloroauric acid solution (70 mg / ml) with 100 ml of deionized water, heat to boiling, then add dropwise 700 μl of sodium citrate solution (2 wt %), and heat for 15 minutes to obtain a gold nanoparticle solution. 0.7 g of cysteine was dissolved in 100 ml of deionized water to obtain solution A. 0.7 g of sodium molybdate was dissolved in 100 ml of deionized water to obtain solution B. Solution A and solution B were mixed and sonicated for 2-4 hours at a volume ratio of 2:1. 50ml of gold nanoparticle solution was added to 20ml of 2% polyethylene glycol solution, then mixed with the ultrasonic mixture of A and B above, and then subjected to hydrothermal reaction at 200°C for 16h. After the reaction, the solution was dried in an oven at 110°C for 36 hours to obtain a gold nanoparticle / molybdenum sulfide core-shell nanomaterial.

[0025] Characterization: Take 0.1 g of gold nanoparticles / molybdenum sulfide core-shell nanomaterials and disperse them in 100 ml...

Embodiment 3

[0027] Mix 200 μl of chloroauric acid solution (80 mg / ml) with 100 ml of deionized water, heat to boiling, then add dropwise 700 μl of sodium citrate solution (3 wt %), and heat for 10 minutes to obtain a gold nanoparticle solution. 0.8 g of cysteine was dissolved in 100 ml of deionized water to obtain solution A. 0.8 g of sodium molybdate was dissolved in 100 ml of deionized water to obtain solution B. Solution A and solution B were mixed and sonicated for 2-4 hours at a volume ratio of 2:1. Add 60ml of gold nanoparticle solution into 30ml, 3%, polyethylene glycol solution, and then mix with the above-mentioned ultrasonic mixture of A and B, and then carry out hydrothermal reaction at 200°C for 18h. After the reaction, the solution was dried in an oven at 110°C for 48 hours to obtain a gold nanoparticle / molybdenum sulfide core-shell nanomaterial.

[0028] Characterization: Take 0.1 g of gold nanoparticles / molybdenum sulfide core-shell nanomaterials and disperse them in 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com