Extraction technology of egg yolk immunoglobulins

A technology of egg yolk immunoglobulin and extraction process, applied in immunoglobulin, antibacterial immunoglobulin, immunoglobulin from eggs, etc. The mortality rate and the inability to achieve large-scale production, etc., achieve the effects of easy control of the extraction process, low extraction cost and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

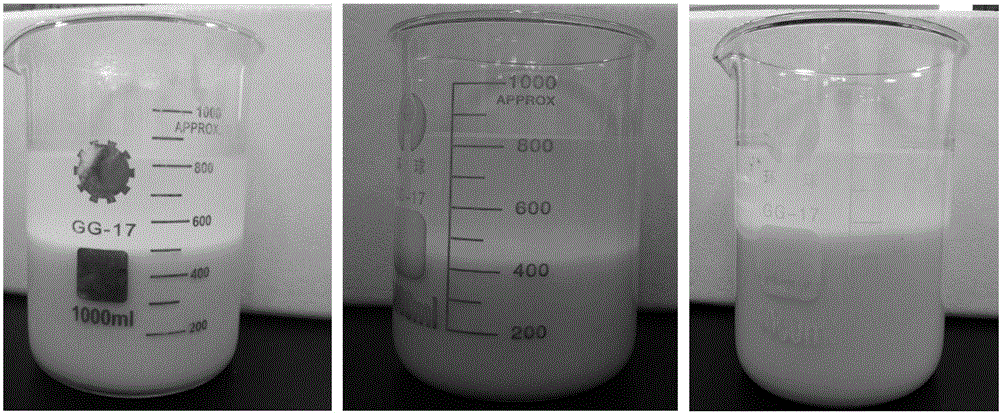

Image

Examples

Embodiment 1

[0027] Example 1: Acquisition of eggs

[0028] 1) Under aseptic conditions, draw Porphyromonas gingivalis (source to be supplemented) on Columbia blood agar plate by four-section line method, and culture in an anaerobic incubator at 37°C for 4 days until black Colony;

[0029] 2) Inoculate the black colony in 3.7% bovine brain heart infusion liquid medium for anaerobic culture for 3 days, and collect Porphyromonas gingivalis by centrifugation;

[0030] 3) Inactivate Porphyromonas gingivalis with 1% formaldehyde, overnight at 4°C, wash 3 times with sterile PBS buffer, and then wash with a concentration of 1.0×10 11 CFU / ml of inactivated bacteria 1ml and the same amount of Freund's incomplete adjuvant and Freund's complete adjuvant were blown and mixed respectively to form two water-in-oil injections corresponding to the needs.

[0031] 4) Healthy laying hens are immunized 4 times first, and each chicken is injected with 1.0ml each time. The first immunization is an injection ...

Embodiment 2

[0032] Embodiment 2: Extraction of yolk globulin

[0033] 1) Wash and sterilize the eggs, break the shell, remove the egg white and yolk coating, stir the egg yolk evenly, freeze at -20°C for 24 hours, thaw quickly, add 9 times the volume of purified water to dilute and stir for 5 hours, adjust the pH with hydrochloric acid solution to 5.0-5.1, stand overnight at 20-23°C;

[0034]2) Centrifuge the egg yolk dilution at 4°C, take the clear liquid and filter it on a filter column to obtain the filtrate. The filler in the filter column is composed of gauze layers arranged up and down and medical absorbent cotton layers;

[0035] 3) Adopt the ultrafiltration membrane that the molecular weight cut off is 100KD to concentrate the filtrate ultrafiltration 9 times, then use 0.9% sodium chloride solution to replace the ultrafiltration concentrate twice in equal amounts, and replace the gained concentrate according to the ratio of 1ml:0.243g Ammonium sulfate was added to the mixture, fu...

Embodiment 3

[0037] Embodiment 3: Extraction of yolk globulin

[0038] 1) Wash and sterilize the eggs, break the shell, remove the egg white and yolk coating, stir the egg yolk evenly, freeze at -20°C for 48 hours, thaw quickly, add 9 times the volume of purified water to dilute and stir for 5 hours, adjust the pH with hydrochloric acid solution to 5.0-5.1, stand overnight at 20-23°C;

[0039] 2) Centrifuge the egg yolk dilution at 4°C, take the clear liquid and filter it on a filter column to obtain the filtrate. The filler in the filter column is composed of gauze layers arranged up and down and medical absorbent cotton layers;

[0040] 3) Adopt the ultrafiltration membrane that the molecular weight cut off is 100KD to concentrate the filtrate ultrafiltration 9 times, then use 0.9% sodium chloride solution to replace the ultrafiltration concentrate twice in equal amounts, and replace the gained concentrate according to the ratio of 1ml:0.243g Ammonium sulfate was added to the mixture, f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com