Method for preparing gas-bubble water-coal slurry or water-coke slurry by utilizing sludge and organic waste liquid through fermentation

A technology of organic waste liquid and water coke slurry, which is applied in the direction of liquid carbon-containing fuel, petroleum industry, fuel, etc., can solve the problems of unsatisfactory stabilization effect and short stabilization time of only 1-2 days, so as to save pulping cost , prevent coalescence and sedimentation, reduce the effect of additives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

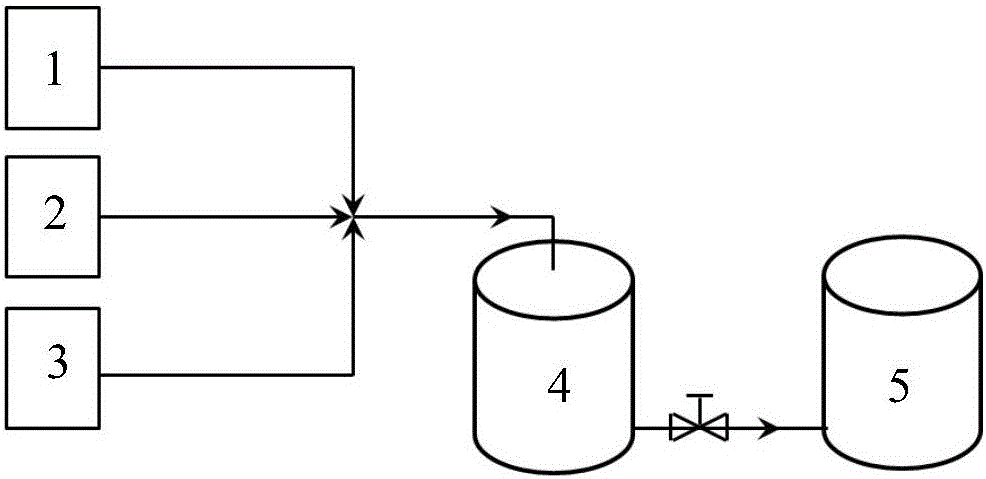

Method used

Image

Examples

Embodiment approach

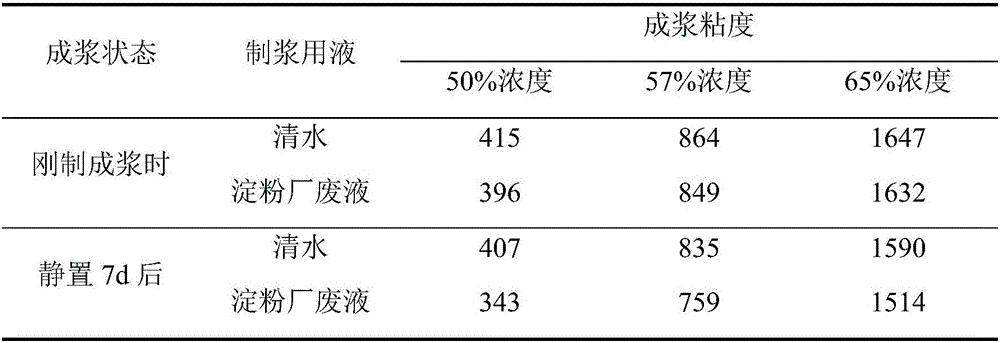

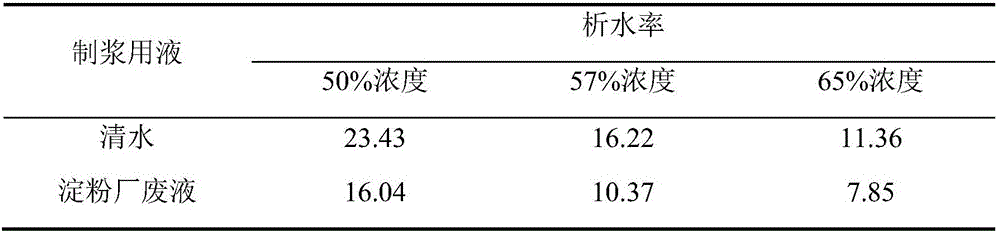

[0028]This example uses petroleum coke, sludge, starch factory waste liquid, and a small amount of additives to make sludge waste water coke slurry, and compares the difference in the effect of starch factory waste liquid and clean water in pulping. When making pulp, keep the mass ratio of petroleum coke, sludge and additives constant, and by changing the amount of waste liquid (or clean water) in the starch factory, mixed slurries with solid mass concentrations of 50%, 57% and 65% are prepared respectively , the mass proportions of the components under the three concentrations are: ① 50% concentration slurry: 47.8% petroleum coke, 42.4% waste liquid (or clean water) from starch factory, 9.5% sludge, 0.3% additive; ② 57% concentration slurry Body: petroleum coke 54.4%, starch factory waste liquid (or clear water) 34.3%, sludge 10.9%, additive 0.4%; ③ 65% concentration slurry: petroleum coke 62.0%, starch factory waste liquid (or clear water) 25.0%, sewage mud 12.5%, additives ...

Embodiment 2

[0040] (1) Implementation method

[0041] Due to the extremely poor stability of the water coke slurry made from petroleum coke, the stability of coal water slurry is much better under the same conditions. Therefore, this example studies the fermentation of sludge and organic waste liquid to produce air bubbles The effect on the stability of water coke slurry.

[0042] The solid mass concentration of the mixed slurry that makes in this example is 62%, and the mass proportion of each raw material component is: petroleum coke 59.1%, organic waste liquid 28.4%, sludge 12.0% (according to sludge water content 80% Converted), additive 0.5%.

[0043] The organic waste liquids used in this example are respectively taken from breweries, starch factories, meat processing plants and catering wastewater, and their chemical oxygen demand (COD) is 2480mg / L, 5910mg / L, 9220mg / L, 11900mg / L respectively. L, waste liquids with different chemical oxygen demand are represented as W1, W2, W3, W4...

Embodiment 3

[0059] (1) Implementation method

[0060] This example uses coal, sludge, winery waste liquid (or clear water), and a small amount of additives to make sludge waste liquid coal-water slurry, and investigates the influence of sludge and brewery waste liquid on the slurrying effect.

[0061] The coal used in this example is Datong bituminous coal, the organic waste liquid is taken from a winery, and the chemical oxygen demand (COD) is 2480mg / L; the sludge is the remaining activated sludge from Hangzhou Qige Sewage Plant, with a moisture content of about 89% ; The additive is sodium lignosulfonate.

[0062] The solid mass concentration of all the slurries prepared in this example is about 60%, and the mass ratio of each component is: ① ordinary clear water coal-water slurry: clear water 40.0%, coal 59.6%, additive 0.4%; ② sludge clear water Coal water slurry: coal 57.6%, clear water 32.0%, sludge 10.0% (converted according to the moisture content of 80%), additives 0.4%; ③ sludg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volatile matter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com