A polymer micelle freeze-dried preparation of taxane antineoplastic drugs and its preparation method and application

A technology of anti-tumor drugs and taxanes, which is applied in the direction of anti-tumor drugs, drug combinations, drug delivery, etc., can solve problems such as safety concerns and poor stability of micelles, and achieve improved safety, high encapsulation efficiency, The effect of eliminating hidden dangers of medication safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Synthesis of polycaprolactone-polyethylene glycol-polycaprolactone block copolymer:

[0037]A polycaprolactone-polyethylene glycol-polycaprolactone block copolymer with a weight ratio of 10:20:10 was prepared by ring-opening polymerization. Under the protection of nitrogen, 40g of polyethylene glycol monomethyl ether (molecular weight: 2000), 40g of caprolactone, and 0.1g of stannous octoate were successively added to the reactor that was fully dried at a high temperature of 60°C for 12 hours, and the reactor was vacuumed. Temperature <1mmHg, seal the reactor, heat up to 130°C for 12h, cool, add 160ml of dichloromethane to dissolve and dilute, add 160ml of purified water and stir at room temperature for 24h, let stand to separate layers, and dry the dichloromethane layer with anhydrous magnesium sulfate After suction filtration, the filtrate was precipitated with 3200 ml of anhydrous ether and then vacuum-dried to obtain a white solid product.

[0038] The white solid ...

Embodiment 2

[0040] Synthesis of polyethylene glycol monomethyl ether-polycaprolactone block copolymer:

[0041] A polyethylene glycol monomethyl ether-polycaprolactone block copolymer with a weight ratio of 50:50 was prepared by ring-opening polymerization. Under the protection of nitrogen, 50g of polyethylene glycol monomethyl ether (molecular weight: 2000), 50g of caprolactone, and 1g of stannous octoate were successively added to the reactor that was fully dried at a high temperature of 100°C for 4 hours, and the reactor was sealed and filled with dry nitrogen. Pressurize to >4kg, heat up to 180°C to react for 1h, cool, add 50ml of dichloromethane to dissolve and dilute, add 10ml of deionized water and stir at room temperature for 12h, stand to separate layers, dry the dichloromethane layer with anhydrous magnesium sulfate, and pump filtered, the filtrate was concentrated to dryness, added water to dissolve, and obtained a blank polymer micelle solution, which was concentrated by ultra...

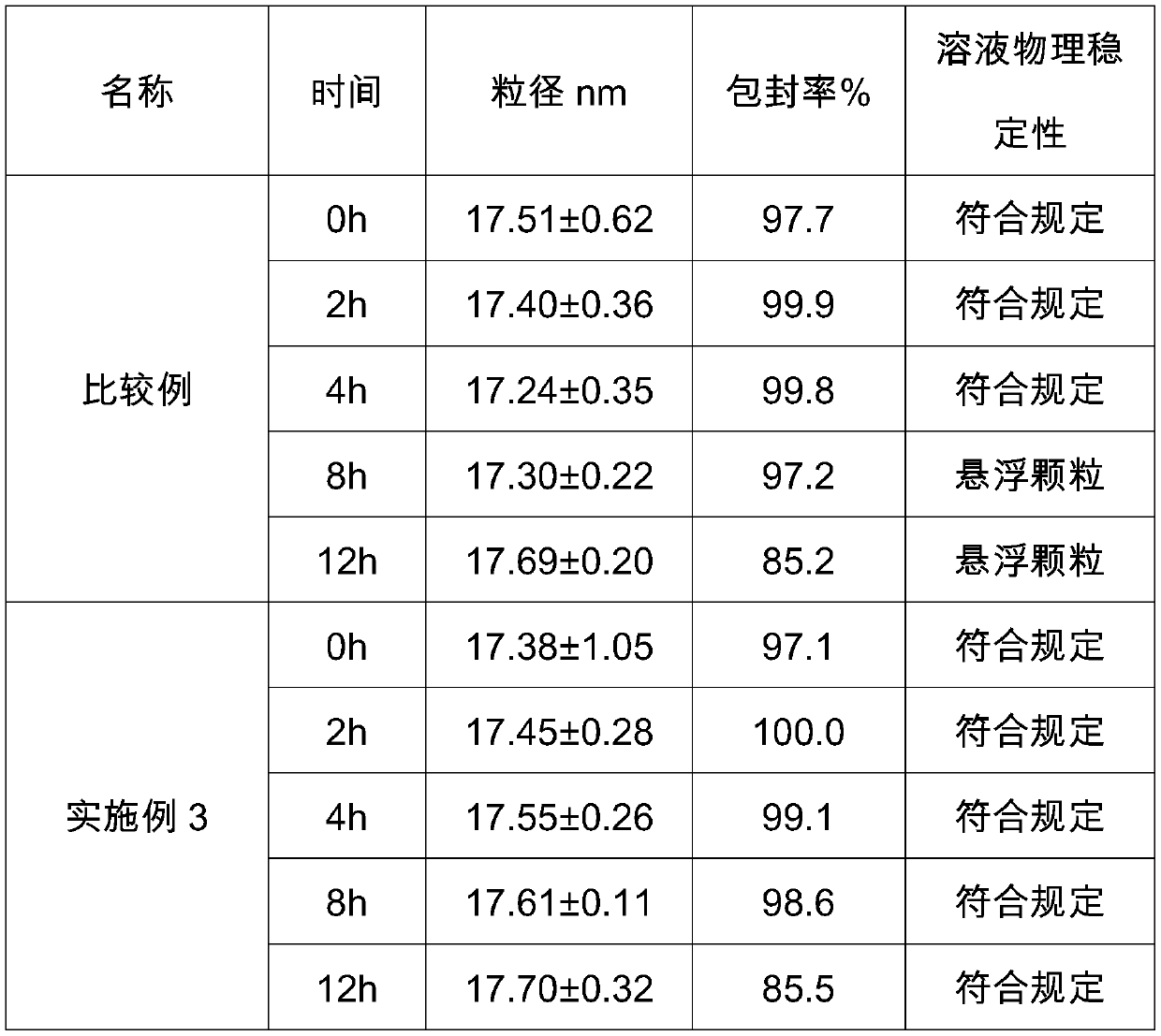

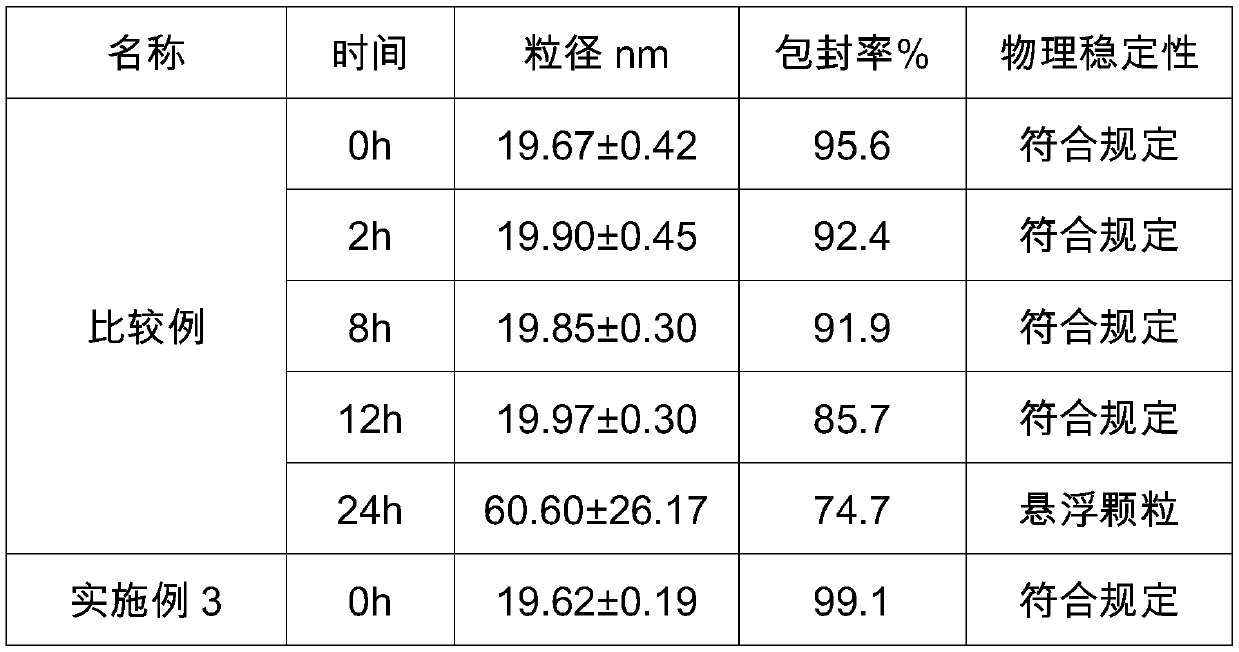

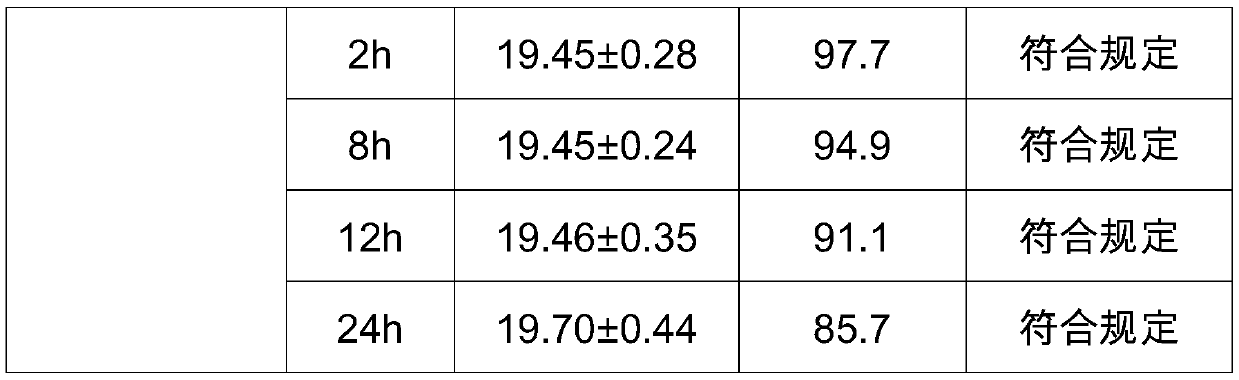

Embodiment 3

[0043] Synthesis of polyethylene glycol monomethyl ether-poly(D,L) lactide block copolymer:

[0044] A polyethylene glycol monomethyl ether-poly(D,L) lactide block copolymer with a weight ratio of 50:50 was prepared by ring-opening polymerization. Under nitrogen protection, add 50g of polyethylene glycol monomethyl ether (molecular weight: 2000), 50g of D, L-lactide, and 0.5g of stannous octoate into the reactor that has been fully dried at a high temperature of 120°C for 1 hour, and seal the reactor. , filled with dry nitrogen and pressurized to >2kg, heated to 150°C to react for 4 hours, cooled, added 100ml of dichloromethane to dissolve and dilute, then added 100ml of water for injection and stirred at room temperature for 24h, stood to separate layers, and dichloromethane layer was washed with anhydrous sulfuric acid Magnesium is dried and filtered with suction, the filtrate is concentrated to dryness, and dissolved in water for injection to obtain a blank polymer micelle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com